Stable arsenic acid iron slag solidifying method

A technology of iron arsenate slag and solidification method, which is applied in the direction of improving process efficiency, etc., can solve the problems of high cost and large amount of ferrous sulfate, and achieve the effect of large specificity, high strength and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

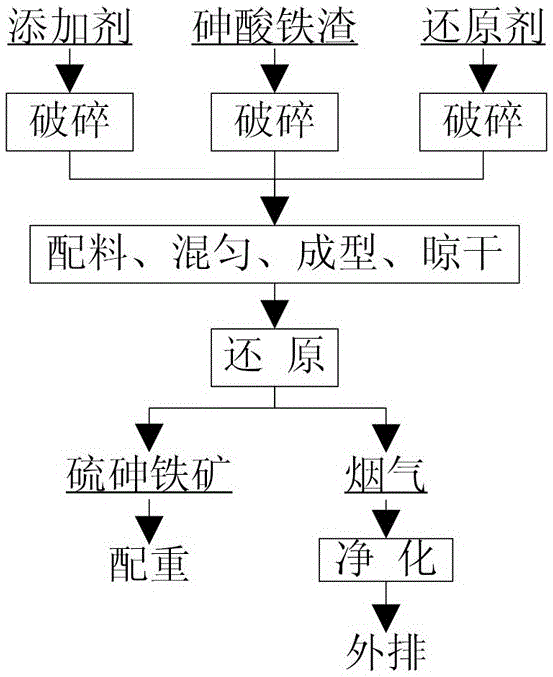

[0027] A method for stable solidification of iron arsenate slag, including the following steps:

[0028] (1) The iron arsenate slag, additives and reducing agent are firstly crushed separately so that the raw material particles with a particle size of less than 120μm account for more than 98%, and then mixed uniformly to obtain a mixed raw material.

[0029] (2) Place the mixed raw materials in a molding mold for molding (preferably tablet molding), the molding pressure is 6.2MPa, the molding temperature is room temperature, and the pressure holding time is 7.5s to obtain a molded part, which is dried for 48h after demolding.

[0030] (3) Put the dried parts into an electric furnace for reduction (specifically carbothermic reduction), turn on the electric dust collection, control the reduction temperature to 800℃, and the reduction time to 2.5h. After reduction, sulfur and arsenic are obtained. Iron ore and arsenic pyrite can be used for weighting, and the flue gas produced by reduct...

Embodiment 2

[0038] A method for stable solidification of iron arsenate slag, including the following steps:

[0039] (1) The iron arsenate slag, additives and reducing agent are firstly crushed separately so that the raw material particles with a particle size of less than 120μm account for more than 98%, and then mixed uniformly to obtain a mixed raw material.

[0040] (2) Place the mixed raw materials in a molding die for molding (preferably tablet molding), the molding pressure is 7.0 MPa, the molding temperature is room temperature, and the pressure-holding time is 4.6 s to obtain molded parts, which are dried for 48 hours after demolding.

[0041] (3) Put the dried parts into an electric furnace for reduction, turn on the electric dust collector, control the reduction temperature to 1050℃, and the reduction time to 2.0h. After reduction, pyrite and pyrite are obtained. It can be used for counterweight, and the flue gas produced by reduction is discharged after purification.

[0042] In this ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com