Method for simultaneously extracting oil and protein and/or glucoside in moringa seeds

A technology of Moringa seed oil and Moringa seed, which is applied in the direction of fat oil/fat production, fat production, fermentation, etc., can solve the problems of insufficient comprehensive utilization and low extraction rate of Moringa seed oil, and achieve easy promotion and comprehensive utilization Value, the effect that the health care function is strong

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

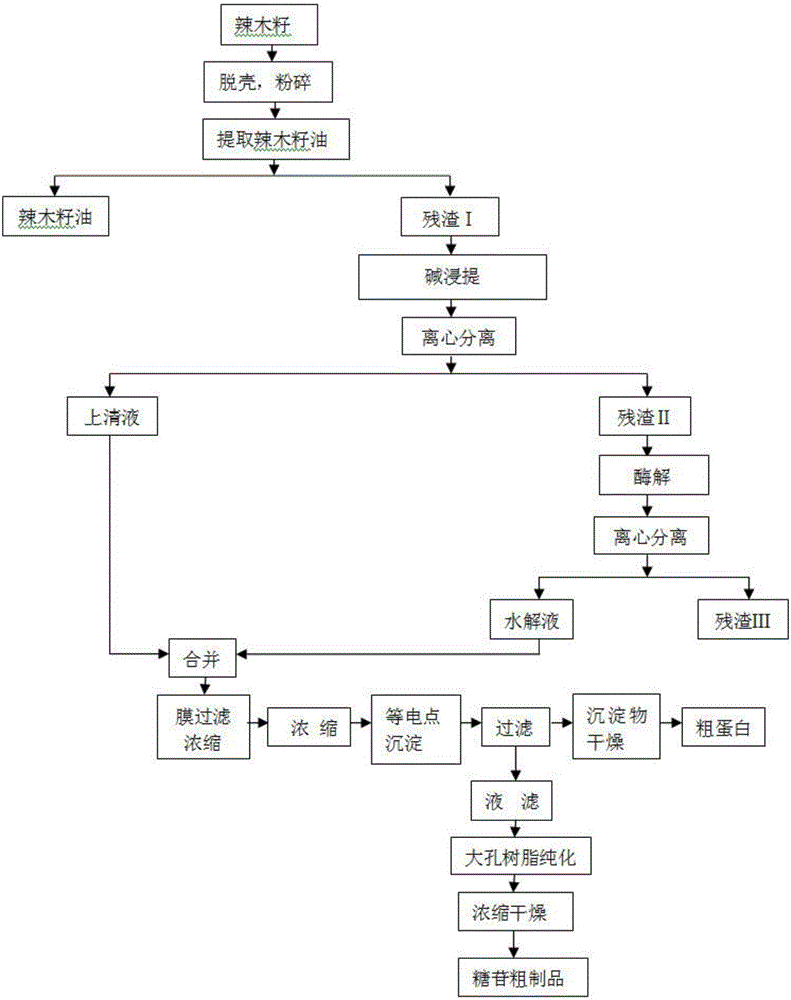

[0075] Embodiment 1 Grease and crude protein preparation

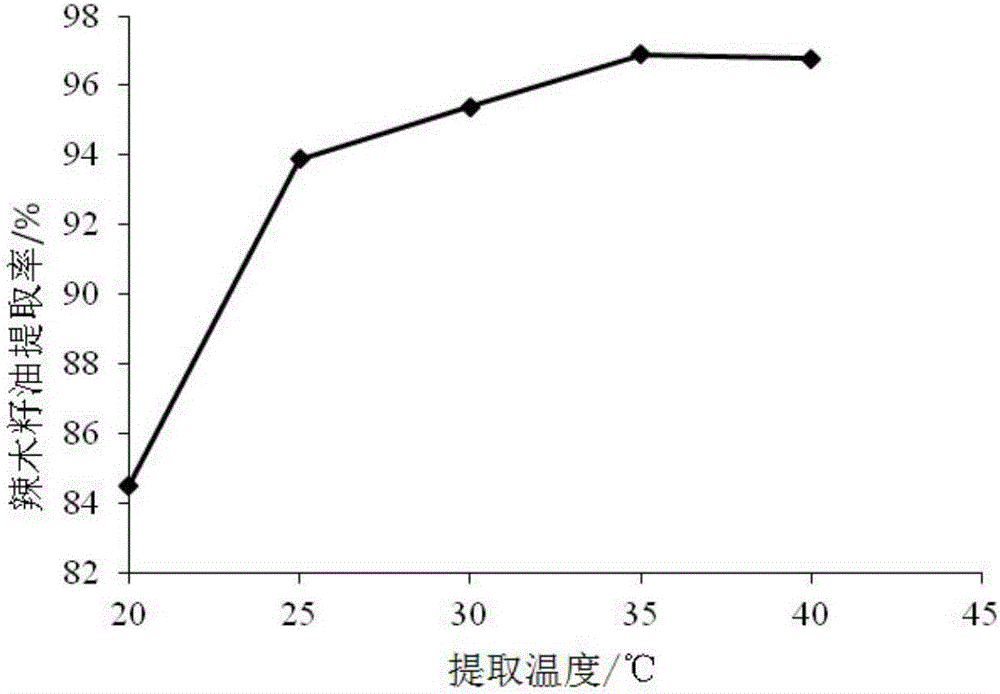

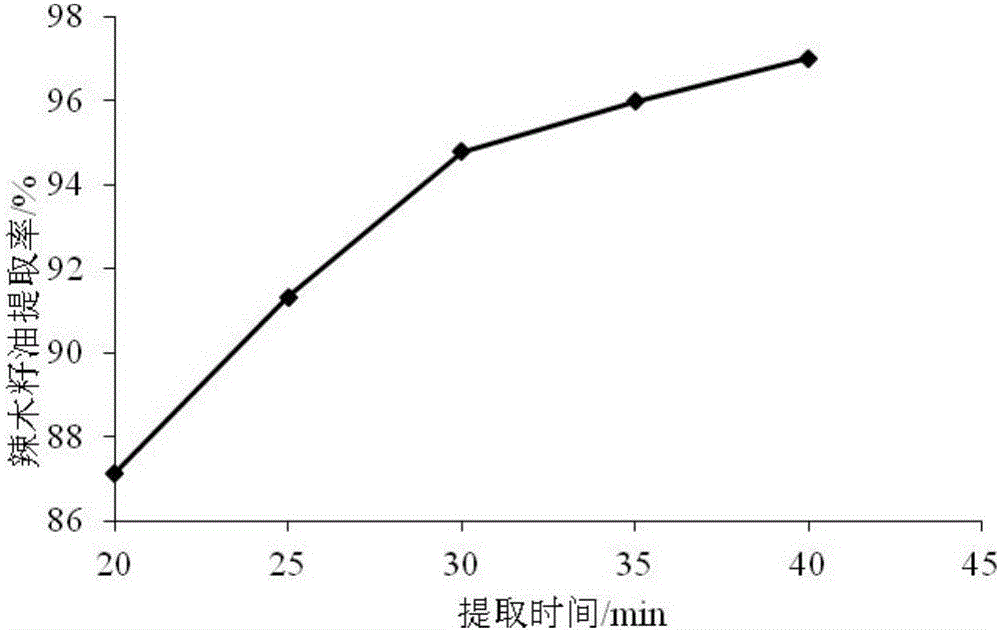

[0076] S1. Extract Moringa oleifera seed oil: Dehull and pulverize moringa oleifera seeds and use subcritical fluid extraction to extract oil and get moringa oleifera seed oil and residue I; the extraction agent is butane, and the ratio of solid to liquid is 1:2 (g / mL), the extraction temperature is 30°C, the extraction time is 40min, and the extraction times are 2 times;

[0077] S2. Ultrasonic treatment: take the residue I after extracting Moringa oleifera seed oil in step S1, add a sodium hydroxide solution with a pH of 8.0 according to a solid-liquid ratio of 1:5 (g / mL), and then ultrasonically treat it at 300W and 50°C 15min.

[0078] S3. Enzymolysis: After ultrasonic treatment, the mixture is centrifuged to obtain supernatant and residue. Mix the residue with water at a ratio of 1:8 (g / mL). Cellulase was added to the mixed solution in an amount of 0.1% of the mass of the residue II, and then extracted at 30° ...

Embodiment 2

[0082] Embodiment 2 fat and crude protein preparation

[0083] S1. Extract Moringa oleifera seed oil: Dehull and pulverize Moringa oleifera seeds and use subcritical fluid extraction method for oil extraction to obtain Moringa oleifera seed oil and residue I; the extraction agent is propane, and the ratio of solid to liquid is 1:3 (g / mL ), the extraction temperature is 50°C, the extraction time is 20min, and the extraction times are 3 times;

[0084] S2. Ultrasonic treatment: take the residue I after extracting Moringa oleifera seed oil from S1, add sodium hydroxide solution with a pH of 9.0 according to a solid-liquid ratio of 1:10 (g / mL), and then ultrasonicate at 400W and 60°C for 20min.

[0085] S3. Enzymolysis: After ultrasonic treatment, the mixture is centrifuged to obtain supernatant and residue. Mix the residue with water at a solid-liquid ratio of 1:12 (g / mL). Protease was added to the mixture in an amount of 0.5% of the mass of the residue II, and then extracted a...

Embodiment 3

[0089] Embodiment 3 fat and crude protein preparation

[0090] S1. Extract Moringa oleifera seed oil; perform solvent extraction according to conventional methods to obtain oil and residue I.

[0091] S2. Ultrasonic treatment: Take the residue I after solvent extraction of Moringa oleifera seed oil, add sodium hydroxide solution with a pH of 10.0 according to a solid-liquid ratio of 1:15 (g / mL), and then ultrasonicate at 500W and 75°C for 15min.

[0092] S3. Enzymolysis: After ultrasonic treatment, the mixture is centrifuged to obtain supernatant and residue. Mix the residue with water at a solid-liquid ratio of 1:15 (g / mL). Add alkaline protease to the mixed solution first, and then add cellulase after enzymolysis for 1.5 hours. The total amount of the two enzymes added is 1.0% of the mass of residue II, and the ratio is alkaline protease: cellulase = 1:2 (w / w), and then stirred and extracted at 50° C. for 6.0 h to obtain an enzymatic hydrolysis solution.

[0093] S4. Enzy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com