High-solid circulating anaerobic reactor

An anaerobic reactor, high-solid technology, applied in solid-phase fermentation bioreactor, bioreactor/fermenter combination, specific-purpose bioreactor/fermenter, etc., can solve difficult manufacturing, inconvenient maintenance, etc. Material deposition and other problems, to achieve the effect of strong adaptability, convenient manufacturing and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

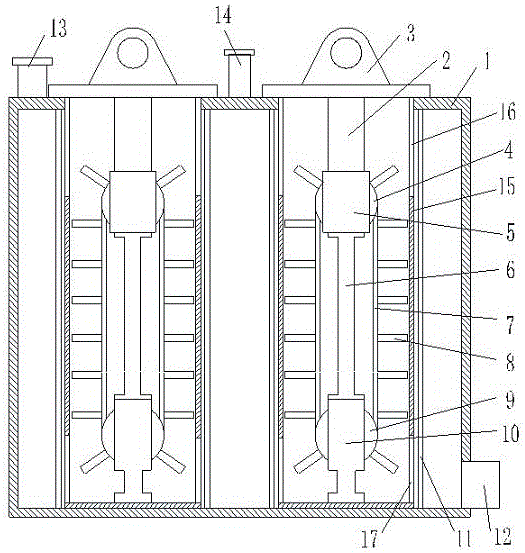

[0021] Such as figure 1 As shown, the high-solid circulation anaerobic reactor of the present invention includes a tank body 1 and at least one turning unit, and each turning unit is vertically or obliquely arranged in the tank body 1 . figure 1 Two copying units are drawn in the middle, and the specific number can be determined according to the experiment according to the inner diameter of the tank body 1 and the required processing effect and efficiency. The top cover of the tank body 1 is provided with a feeding port 13 and an exhaust port 14, and a sewage discharge port 12 is provided at the bottom. Solid waste is filled into the tank body 1 through the feeding port 13 , biogas produced by fermentation is discharged through the exhaust port 14 , and biogas residue and biogas slurry can be discharged through the sewage discharge port 12 . The sewage outlet 12 is arranged at the bottom of the side of the tank body 1 opposite to the feeding port 13, so that the feed material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com