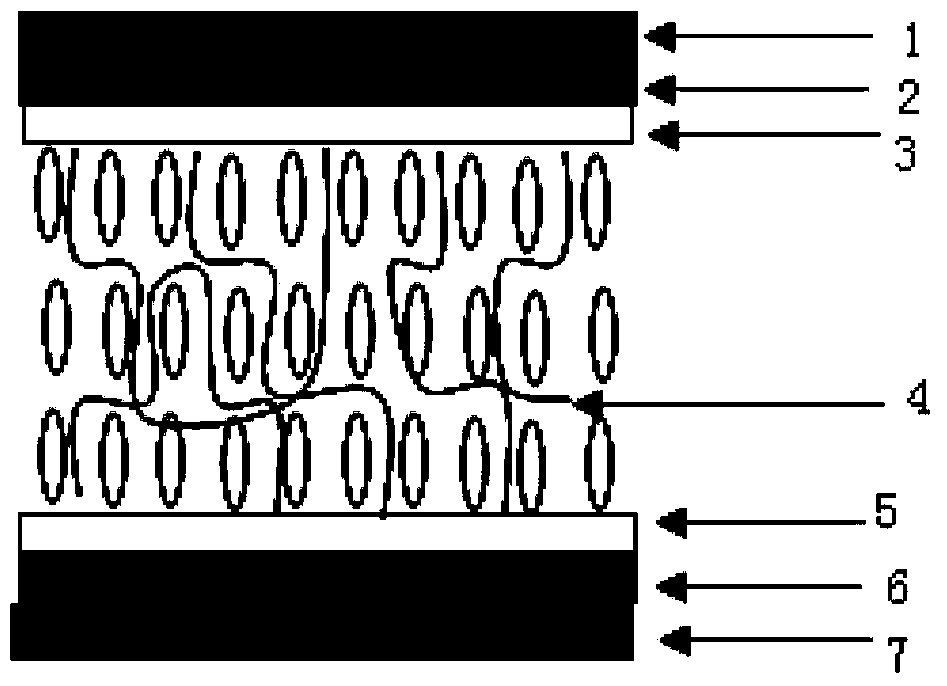

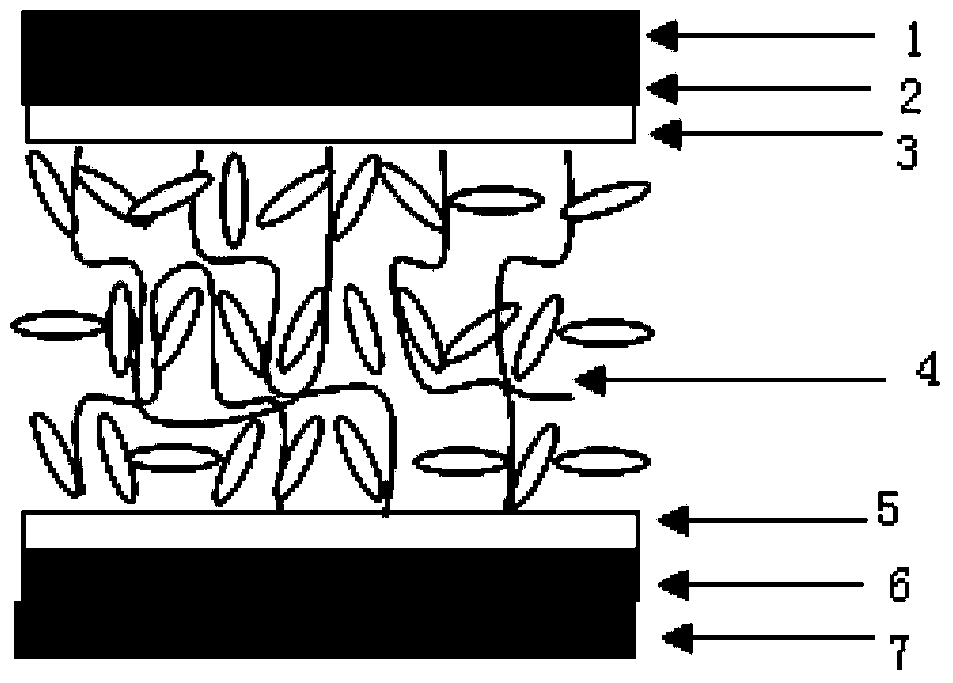

polymer network liquid crystal display

A liquid crystal display and polymer technology, applied in liquid crystal materials, instruments, chemical instruments and methods, etc., can solve the problems of low light transmittance, the contrast and light transmittance of display devices are difficult to meet the needs of technological development, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

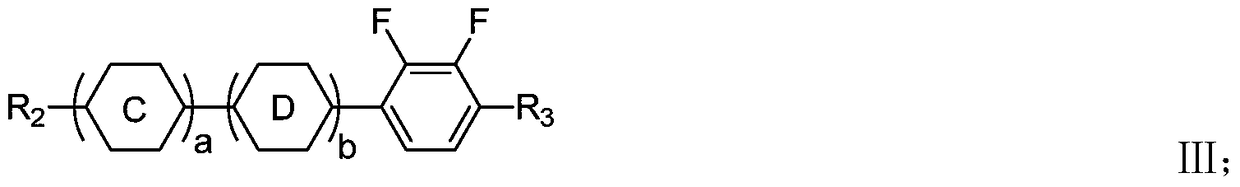

Method used

Image

Examples

Embodiment 1

[0171] The liquid crystal composition HNG700200-100 was formulated according to the compounds and weight percentages listed in Table 2, and it was filled between the two substrates of the liquid crystal display for performance testing. The test data are shown in the following table:

[0172] Table 2 Liquid crystal composition formula and its test performance

[0173]

[0174] After mixing HNG700200-100, Ⅰ-2-2, and photoinitiator-184 uniformly in a mass ratio of 94:5.9:0.1, vacuum pour it into a 6um vertically aligned liquid crystal cell, and place the liquid crystal cell filled with the mixture in the main light The wavelength is 365nm, the light intensity is 15mw / cm 2 Curing at room temperature for 5 min under a UV lamp to obtain a PNLC film. The light transmittance of the prepared PNLC film without an electric field is 86%, and a voltage of 30V is applied to the PNLC film. At this time, the light transmittance of the PNLC film is 6.6%, and the contrast is 13. At a viewin...

Embodiment 2

[0177] The liquid crystal composition HNG720200-100 was formulated according to the compounds and weight percentages listed in Table 3, and it was filled between the two substrates of the liquid crystal display for performance testing. The test data are shown in the following table:

[0178] Table 3 Liquid crystal composition formula and its test performance

[0179]

[0180] After mixing HNG720200-100, Ⅰ-1-1, and photoinitiator-184 uniformly in a mass ratio of 94:5.9:0.1, vacuum pour it into a 6um vertically aligned liquid crystal cell, and place the liquid crystal cell filled with the mixture in the main light The wavelength is 365nm, the light intensity is 20mw / cm 2 Curing at room temperature for 5 min under a UV lamp to obtain a PNLC film. The light transmittance of the prepared PNLC film without an electric field is 86%. Apply a voltage of 30V to the PNLC film. At this time, the light transmittance of the PNLC film is 9.5%, and the contrast ratio is 9. When the viewin...

Embodiment 3

[0182]The liquid crystal composition HNG721600-100 was formulated according to the compounds and weight percentages listed in Table 4, and it was filled between the two substrates of the liquid crystal display for performance testing. The test data are shown in the following table:

[0183] Table 4 Liquid crystal composition formula and its test performance

[0184]

[0185] After mixing HNG721600-100, polymers Ⅰ-2-2 and Ⅱ-1-2, and photoinitiator-184 in a mass ratio of 92:5.9:2:0.1, vacuum pour them into a 6um vertically aligned liquid crystal cell. Put the liquid crystal cell filled with the mixture under the main light wavelength of 365nm and the light intensity of 15mw / cm 2 Curing at room temperature for 5 min under a UV lamp to obtain a PNLC film. The light transmittance of the prepared PNLC film without an electric field is 87%, and a voltage of 30V is applied to the PNLC film. At this time, the light transmittance of the PNLC film is 6.2%, and the contrast is 14. At ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com