Low-damage acid liquor used for oil and gas well acidizing and preparation method thereof

A technology for oil and gas wells and acid solutions, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of weakened chelating agent chelation, low solubility, weak acidity, etc., so as to slow down acid-rock reaction and prevent secondary Minor damage, stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

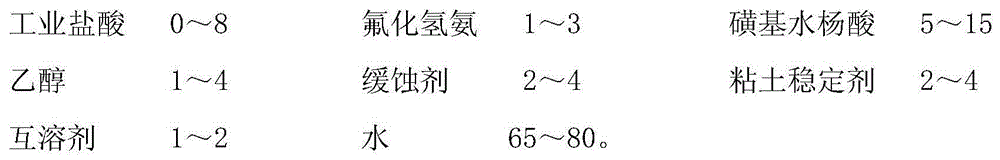

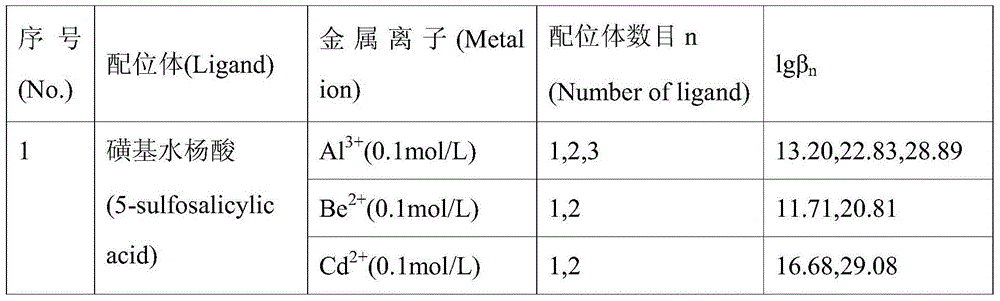

Method used

Image

Examples

Embodiment 1

[0040] First add 65 kg of water into the reaction kettle, then add 15 kg of sulfosalicylic acid, 1 kg of ammonia hydrogen fluoride, 4 kg of ethanol, and 1 kg of ethylene glycol monobutyl ether in sequence at 15°C under stirring, and continue stirring for 50 minutes. Then add 2 kg of NH 4 Cl, 4 kg of corrosion inhibitor compounded by hexamethylenetetramine and thiourea according to the ratio of 1:2.2 parts by weight, stirred for 20 minutes, and mixed to obtain the product.

Embodiment 2

[0042] First add 80 kg of water to the reaction kettle, then add 5 kg of sulfosalicylic acid, 3 kg of ammonia hydrogen fluoride, 1 kg of ethanol, and 2 kg of ethylene glycol monobutyl ether in sequence at 30°C under stirring, and continue stirring for 20 minutes. Then add 4 kg of NH 4 Cl, 2 kg of corrosion inhibitor compounded by hexamethylenetetramine and thiourea according to the ratio of 1:1.8 parts by weight, stirred for 40 minutes, and mixed to obtain the product.

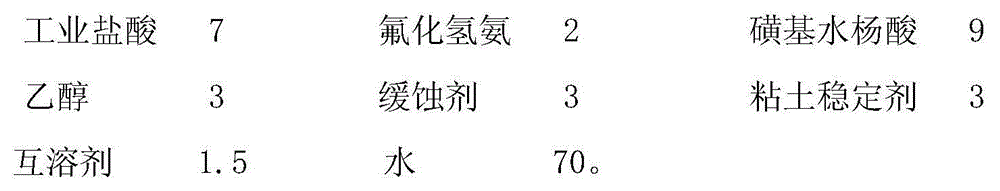

Embodiment 3

[0044] First add 70 kg of water to the reaction kettle, then add 9 kg of sulfosalicylic acid, 2 kg of ammonia hydrogen fluoride, 3 kg of ethanol, and 1.5 kg of ethylene glycol monobutyl ether in sequence at 22°C with stirring, and continue stirring for 35 minutes. Then add 3 kg of NH 4 Cl, 3 kg of a corrosion inhibitor compounded by hexamethylenetetramine and thiourea in a ratio of 1:2 parts by weight, stirred for 30 minutes, and mixed to obtain a product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com