Graphene-containing polyurethane antimicrobial adhesive and preparation method thereof

A graphene and antibacterial glue technology, applied in adhesive additives, non-polymer adhesive additives, etc., can solve the problems of bacteria, mold growth, affecting the aesthetics, service life and practical functions of the application carrier, and improve antibacterial performance, remarkable technological progress, and unique effects of technical formulas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

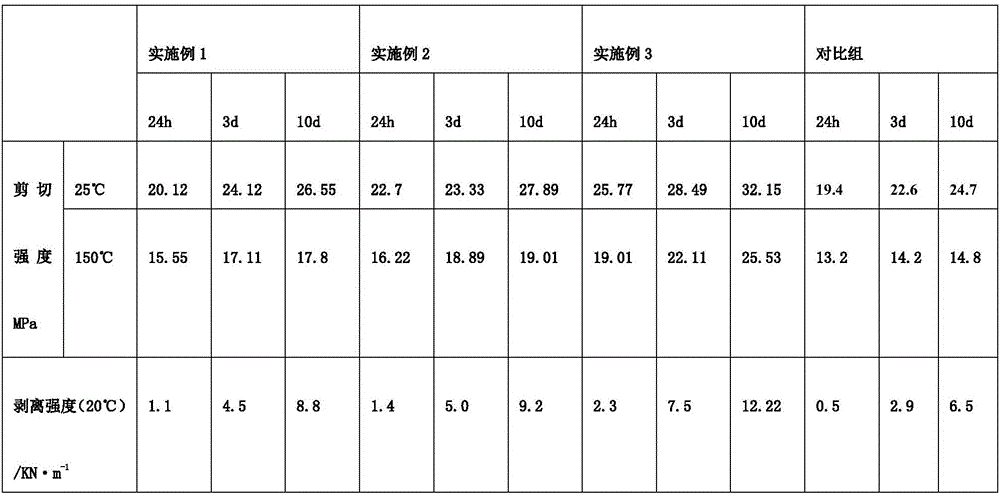

Embodiment 1

[0042] Embodiment 1: a kind of polyurethane antibacterial adhesive with graphene, a kind of polyurethane antibacterial adhesive with graphene, is made of the raw material of following parts by weight: polytetrahydrofuran diol (molecular weight 3000) 60 parts, diphenyl 10 parts of methyl methane diisocyanate, 1 part of graphene oxide, 1.0 parts of polyoxyethylene polyoxypropylene pentaerythritol ether, 0.10 parts of Dabco33-LV, 15 parts of diisooctyl phthalate, p-toluenesulfonyl isocyanate 0.07 parts, 0.07 parts of γ-aminopropyltriethoxysilane, and 0.10 parts of 3,5-di-tert-butyl-4-hydroxyphenylpropionic acid octadecanoate.

[0043] Concrete preparation steps are:

[0044] 1) Weigh 600g of polytetrahydrofuran diol with a molecular weight of 3000 and put it into a reaction kettle, stir and heat to 100°C, and vacuumize and dehydrate for 4 hours;

[0045] 2) Add 10 g of polyoxyethylene polyoxypropylene pentaerythritol ether to polytetrahydrofuran diol cooled to room temperature a...

Embodiment 2

[0049] Embodiment 2: a kind of polyurethane antibacterial adhesive with graphene is made of the raw materials of following parts by weight: polytetrahydrofuran diol (molecular weight 3000) 60 parts, diphenylmethane diisocyanate 10 parts, graphene oxide 1.5 parts , 1.0 parts of polyoxyethylene polyoxypropylene pentaerythritol ether, 0.10 parts of Dabco33-LV, 15 parts of diisooctyl phthalate, 0.07 parts of p-toluenesulfonyl isocyanate, γ-aminopropyl triethoxy 0.07 parts of silane, 0.10 parts of 3,5-di-tert-butyl-4-hydroxyphenylpropionic acid octadecanoate.

[0050] Concrete preparation steps are:

[0051] 1) Weigh 600g of polytetrahydrofuran diol with a molecular weight of 3000 and put it into a reaction kettle, stir and heat to 100°C, and vacuumize and dehydrate for 4 hours;

[0052] 2) Add 10 g of polyoxyethylene polyoxypropylene pentaerythritol ether to polytetrahydrofuran diol cooled to room temperature after dehydration treatment, and mechanically stir to obtain a combined...

Embodiment 3

[0056] Embodiment 3: a kind of polyurethane antibacterial adhesive with graphene is made of the following raw materials in parts by weight: polytetrahydrofuran diol 48g, diphenylmethane diisocyanate 16g, graphene oxide 1.5g, polyoxyethylene polyoxygen Propylene pentaerythritol ether is 0.7g, Dabco33-LV is 0.12g, diisooctyl phthalate is 13g, p-toluenesulfonyl isocyanate is 0.09g, γ-aminopropyltriethoxysilane is 0.13g, 3,5 - 0.08 g of di-tert-butyl-4-hydroxyphenylpropanoic acid octadecanoate.

[0057] Concrete preparation steps are:

[0058] 1) Weigh polytetrahydrofuran diol with a molecular weight of 3000 and put it into a reaction kettle, stir and heat to 100°C, and vacuumize and dehydrate for 4 hours;

[0059] 2) Pour polyoxyethylene polyoxypropylene pentaerythritol ether into polytetrahydrofuran diol cooled to room temperature after dehydration treatment, and mechanically stir to obtain a combined material;

[0060] 3) Add graphene oxide to diphenylmethane diisocyanate, st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com