Preparation method and application of surface-enhanced-Raman-spectrum-sensitive conductive silver ink

A surface-enhanced Raman and conductive silver technology, applied in the direction of copying/marking methods, applications, inks, etc., can solve the problems of small-diameter nozzle clogging, substrates that cannot withstand high temperatures, etc., and achieve good electrical conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

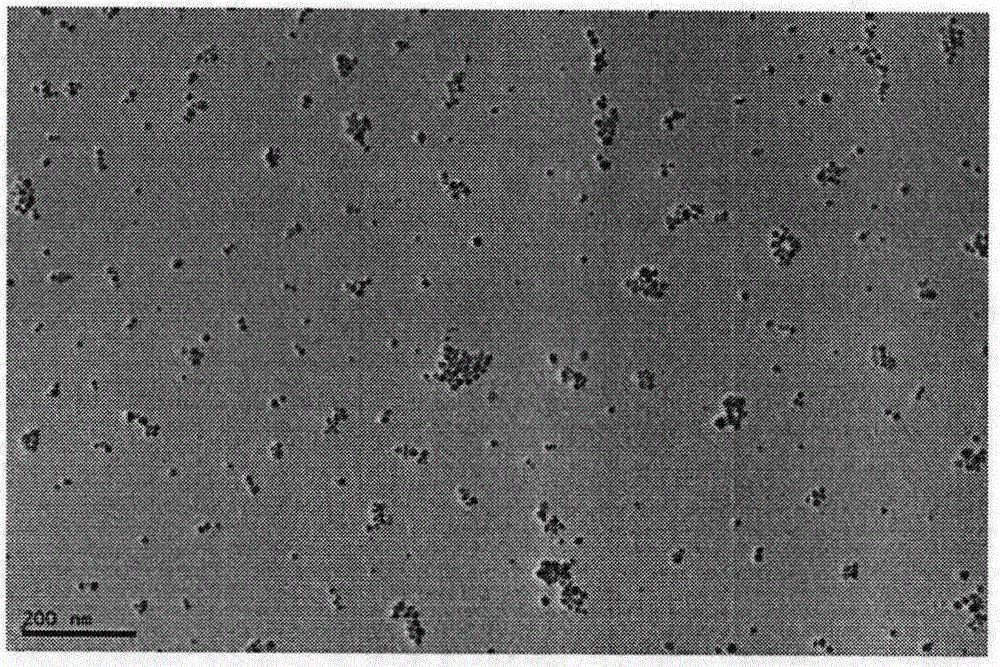

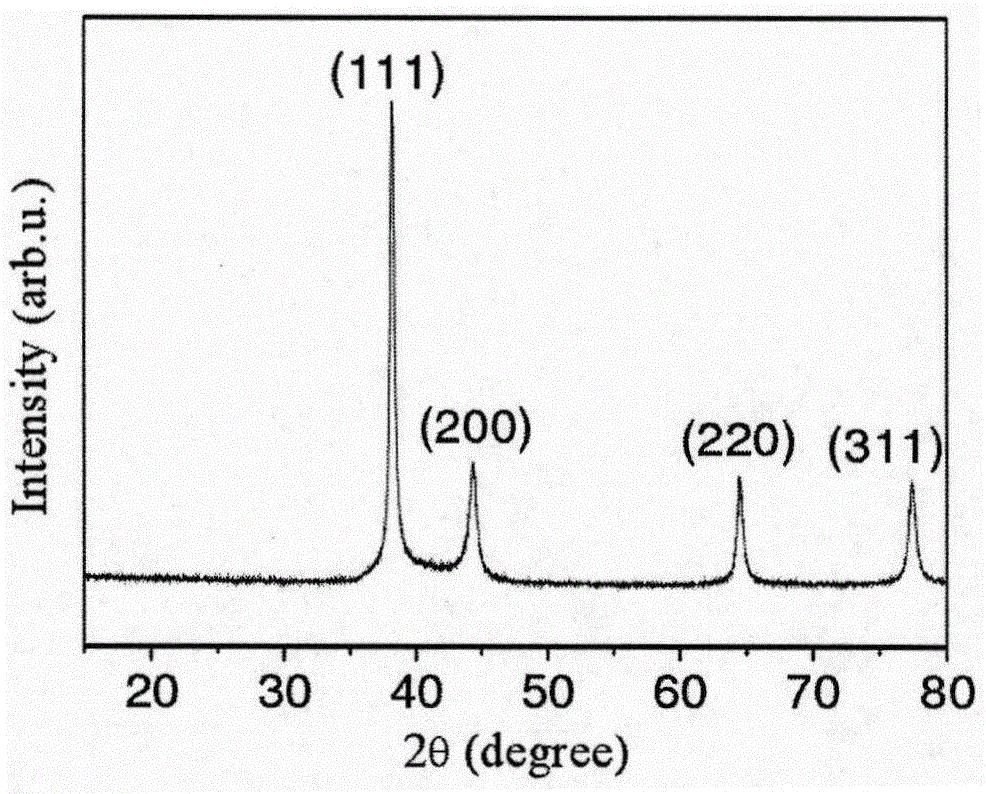

[0043] Step 2, preparation of nano-silver conductive ink

[0044] The self-synthesized nano-silver is dispersed in the water phase solvent, and has good dispersibility in the water phase solvent. Because nano-silver has a small particle size and a very low melting point, the suspension of silver nanoparticles is used as a conductive ink, which can be used to make conductive circuits by inkjet printing. The water-based conductive ink uses a mixed solution of triethylene glycol monoethyl ether and water as the dispersion solvent for nano-silver. Since triethylene glycol monoethyl ether has a relatively high boiling point (256°C), it has moisturizing properties to slow down the drying speed of the ink and avoid particle accumulation. The resulting nozzle clogging can also weaken the "coffee ring" effect of ink droplets. The purified Ag@PVP nanocolloid was used as the conductive phase, and triethylene glycol monoethyl ether, glycerin, and isopropanol were used as the main compone...

Embodiment 1

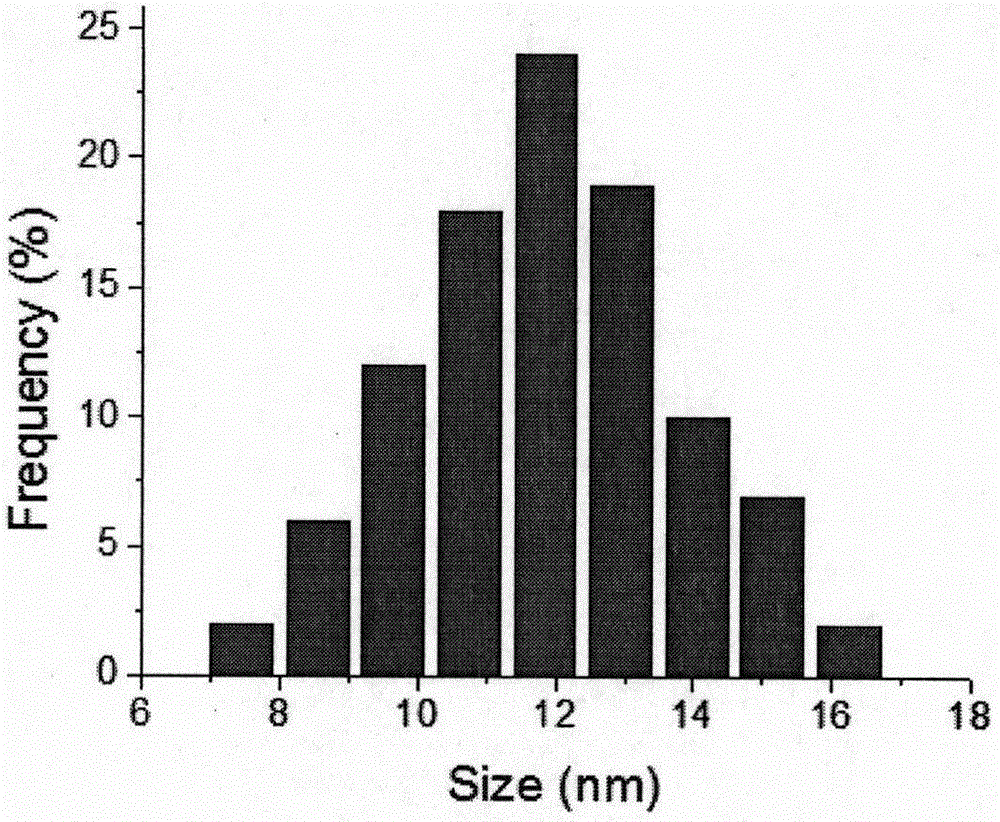

[0059] Synthesis of PAA-coated silver nanoparticles:

[0060] First, weigh a certain amount (0.1g, 0.3g, 0.5g, 0.7g) of polyacrylic acid (PAA) and 1g of silver acetate (CH 3 COOAg), dissolved in 90mL of pure water, heated to a certain temperature (25°C, 50°C, 75°C), stirred at a rate of 500rpm until clear and transparent; then, after weighing 1g of ascorbic acid dissolved in 10mL of pure water, use a trace The syringe pump slowly drips it into the reaction solution at a rate of 60mL / h, adjusts the stirring rate to 700rpm, continues the reaction for 1h, and uses a tangential flow ultrafiltration system to purify and separate the obtained product to remove unreacted Impurities, free ions and excess PAA, etc., were obtained from PAA-coated silver nanoparticles (Ag@PAANPs). The particle size of Ag@PAANPs is concentrated in 10-30nm, the average particle size is 20nm, and the monodispersity is good.

[0061] The purified Ag@PAA nanocolloid was used as the conductive phase, and tri...

Embodiment 2

[0065] Preparation of solution-type silver ink:

[0066] First, weigh 10 g of silver acetate (CH 3 COOAg) was dissolved in a three-necked flask containing 25 mL of ammonia water, protected from light, and stirred at a rate of 500 rpm for 15 min until the solution was clear and transparent; another 2 mL of formic acid (HCOOH) was injected into the reaction at a rate of 8 mL / h using a micro-syringe pump In the solution, adjust the stirring rate to 800rpm, keep away from light, and continue to react for 15 minutes; finally take out the solution, keep it overnight in the dark, take the supernatant, and filter it with a filter membrane with a pore size of 0.22 μm to obtain a stable solution. ink solution.

[0067] Inkjet printing was performed with an Epson Stylus Photo R230 printer. The base material adopts flexible substrate material polyimide (PI). Before printing, use KOH to modify the surface of the PI film to increase the wetting effect of the film and the ink. The specifi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com