Preparation method and application of mucor-fermented soybean bitter peptide

A technology of bitter peptide and fermented soya bean, which is applied in the field of preparation of mucormycin-type fermented fermented soya bean bitter peptide, can solve the problems of poor stability and low purity of bitter peptide, achieve the effect of easy chemical synthesis, high product purity, and broaden the application field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

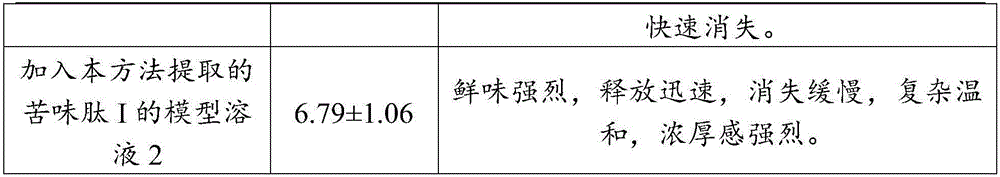

Examples

preparation example Construction

[0032] Such as figure 1 As shown, the preparation method of the Mucor type tempeh bitter peptide of the embodiment of the present invention comprises the following steps:

[0033] S101: Preparation of crude peptide: Accurately weigh a certain amount of tempeh sample (10.00g)→quick freezing in liquid nitrogen→grind into powder in the frozen state→add deionized water (such as 50mL) according to the ratio of material to liquid 1:8-16→ice bath Homogenize for 6min-12min→ultrasonic extraction at 60W-120W for 20min-40min→adjust pH to 5.5-6.5→stir at 45°C for 50min-90min→centrifuge (2000g) at 4°C for 15min-30min→take supernatant→repeat extraction once →Combine the two extracts→centrifuge (10500g) at 4°C for 15min-30min→dialyze the supernatant through a 100Da-200Da dialysis bag for 18h-30h→collect the extract and freeze-dry to obtain crude peptide powder A;

[0034] S102: Dissolve powder A in deionized water to make the concentration reach 5mg / mL-40mg / mL, use NKA-II macroporous resin ...

Embodiment 1

[0057] Preparation of crude peptide: Accurately weigh tempeh sample (10.00g)→quick freezing in liquid nitrogen→grind into powder in frozen state→add deionized water (50mL), homogenate in ice bath (8min)→ultrasonic extraction (80W, 30min)→adjust pH is 6.0→Stir (45°C, 60min)→Centrifuge (2,000g, 4°C, 20min)→Take supernatant→Repeat extraction once, combine two extracts→Centrifuge (10,500g, 4°C, 20min)→Up The clear liquid was dialyzed through a 100Da dialysis bag for 24 hours → the extract was collected and freeze-dried to obtain crude peptide powder A;

[0058] Powder A was dissolved in deionized water to make the concentration reach 5mg / mL, and purified by NKA-II macroporous resin column, first eluted with deionized water to equilibrium, and then eluted with 25% ethanol solution as eluent, Collect the eluted fractions, concentrate and lyophilize to obtain powder B;

[0059] Dissolve powder B in deionized water to reach a concentration of 5 mg / mL, then use Sephadex G-25 gel colum...

Embodiment 2

[0063] Preparation of crude peptide: Accurately weigh tempeh sample (20.00g)→quick freezing in liquid nitrogen→grind into powder in frozen state→add deionized water (320mL), homogenate in ice bath (12min)→ultrasonic extraction (120W, 30min)→adjust pH is 6.5→Stir (45℃, 90min)→Centrifuge (2,000g, 4℃, 30min)→Take supernatant→Repeat extraction once, combine two extracts→Centrifuge (10,500g, 4℃, 30min)→Up The clear liquid was dialyzed by 200Da dialysis bag for 32 hours → the extract was collected and freeze-dried to obtain crude peptide powder A;

[0064] Dissolve powder A in deionized water to make the concentration reach 40mg / mL, use NKA-II macroporous resin column for purification, first elute with deionized water to equilibrium, and then elute with 30% ethanol solution as eluent , collect the eluted fractions, concentrate and freeze-dry to obtain powder B;

[0065] Dissolve powder B in deionized water to reach a concentration of 40mg / mL, then use Sephadex G-25 gel column for p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com