Method for simultaneously preparing methylallyl alcohol and cyclododecanone

A technology of methallyl alcohol and methacrolein, which is applied in the fields of oxidative preparation of carbonyl compounds, reduction preparation of oxygen-containing functional groups, organic chemistry, etc., to achieve the effects of high atom economy, high catalytic activity, and equipment cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

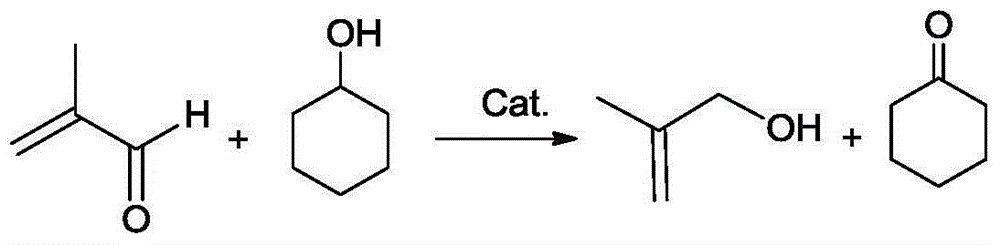

Method used

Image

Examples

Embodiment 1

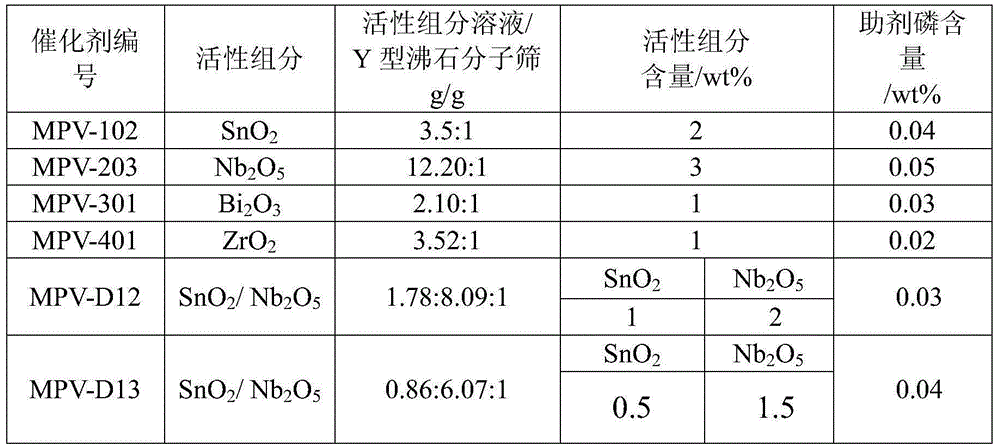

[0038] Preparation of heteroatom-containing Y-type zeolite molecular sieve catalyst:

[0039] Add 3000g nitric acid solution (10wt%) and 600g Y-type zeolite molecular sieve into a 10L glass reactor, reflux at 90°C for 8h, filter after reflux, wash with deionized water until neutral, and dry at 120°C for 8h to obtain a Number of Y-type zeolite molecular sieves.

[0040] Dissolve tin tetrachloride and / or niobium oxalate, bismuth nitrate, and zirconium nitrate in 2% dilute nitric acid solution to obtain an active component solution, the mass concentration of the above solution is 1%, and one or more of the above solutions are used to prepare The obtained Y-type zeolite molecular sieve with a certain number of vacancies was impregnated, and then added a certain amount of auxiliary phosphoric acid, impregnated for 5 hours at 25°C, dried at 120°C for 8 hours after impregnation, and roasted at 550°C for 6 hours to obtain a finished catalyst. The specific composition is shown in Tabl...

Embodiment 2

[0044] Preparation of methallyl alcohol and cyclohexanone:

[0045] Using a 3L stainless steel reactor to synthesize methallyl alcohol and cyclohexanone, first add 1500g methacrolein, 1.5g inhibitor ZJ-701 (p-hydroxytetramethylpiperidine nitroxide free radical) and 45g catalyst, N 2 Replace the air in the system, and ensure a certain pressure, heat, stir, increase the temperature to 90 ° C, add N 2 When the pressure reached 3 bar, 214.3 g of cyclohexanol was gradually added using a parallel flow pump at a rate of 2 g / min. After the cyclohexanol was added, the reaction was continued for a total of 9 hours. After the reaction, use N 2 The materials in the system are pressed out, and the reaction kettle has its own filter head to filter to obtain a mixed solution containing cyclohexanone, methallyl alcohol and methacrolein.

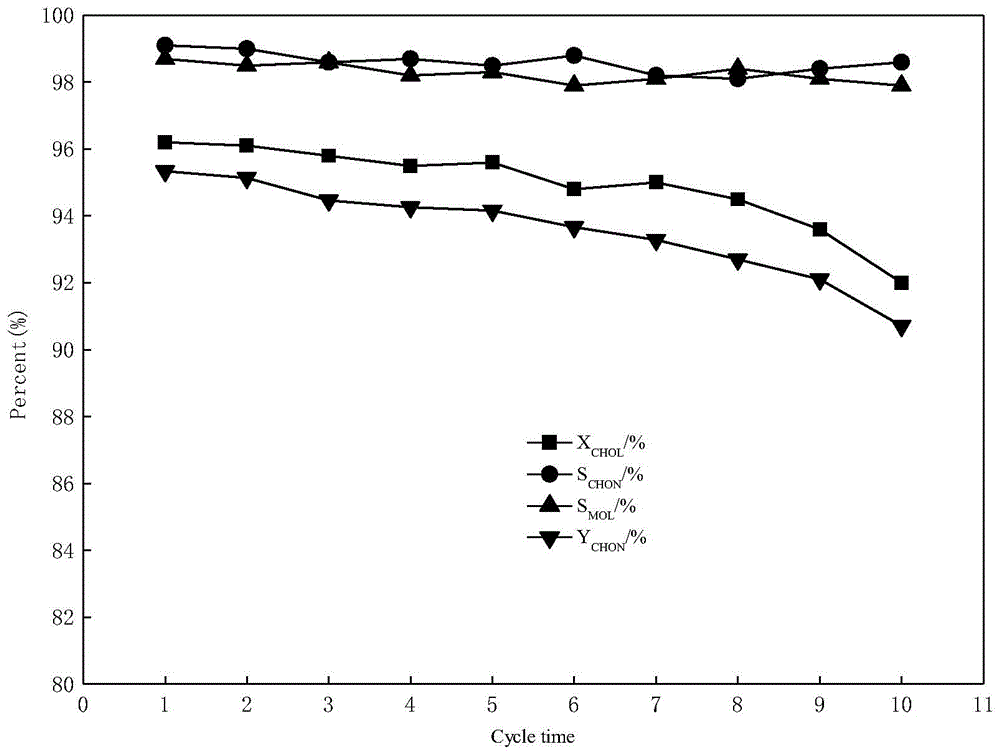

[0046] The product composition was analyzed by gas chromatography. The analysis results are shown in Table 2.

[0047] Table 2 Catalytic performance of...

Embodiment 3

[0054] Different from Example 2, the reaction performance of MPV-D12 catalyst for synthesizing methallyl alcohol and cyclohexanone under different process conditions was investigated. (catalyst consumption is based on the weight of methacrolein)

[0055] Table 3 Catalyst Reaction Performance under Different Process Conditions

[0056]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com