Electrochemical oxidation device for treating desulfurized wastewater

A technology for oxidation treatment and desulfurization wastewater, which is applied in filtration treatment, water/sewage treatment, chemical instruments and methods, etc. It can solve the problems of large alkali consumption, large amount of sludge, large equipment footprint, etc., to save land occupation Smaller area, shortened process, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

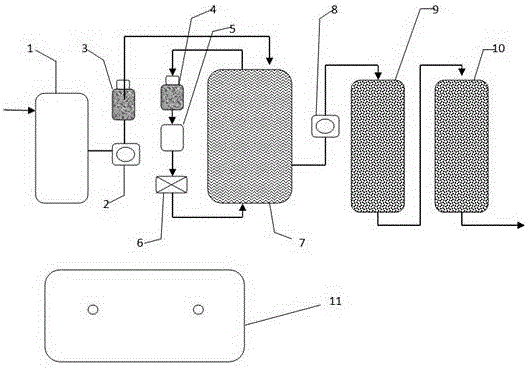

[0019] The present invention will be further explained below in conjunction with the accompanying drawings.

[0020] The invention relates to an electrochemical oxidation device for treating desulfurization wastewater. The electrochemical oxidation device includes: a pretreatment system, an electrochemical reaction system, an adsorption system, and an electrical control system. The desulfurization wastewater is collected and enters the pretreatment tank 1 to adjust the water quality and water quality of the wastewater. The sewage in the pretreatment tank enters the sand filter 3 after the action of the delivery pump 2 to remove large particles of organic matter and sand in the water, and then passes through the intermediate delivery pump 4. The lifting effect enters the wastewater reaction storage tank 7, and circulates through the side-treated electrochemical reactor 5 to degrade the wastewater in the reaction storage tank. The electrochemical reactor 5 has a bag filter 6 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com