Smelting furnace and method used for recycling of by-produced industrial salt

A technology for by-product industry and industrial salt, applied in the direction of alkali metal halide purification, etc., can solve the problems affecting the normal carbonization of inorganic salts, sticking to the wall, shortening the service life of equipment, etc. Design compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

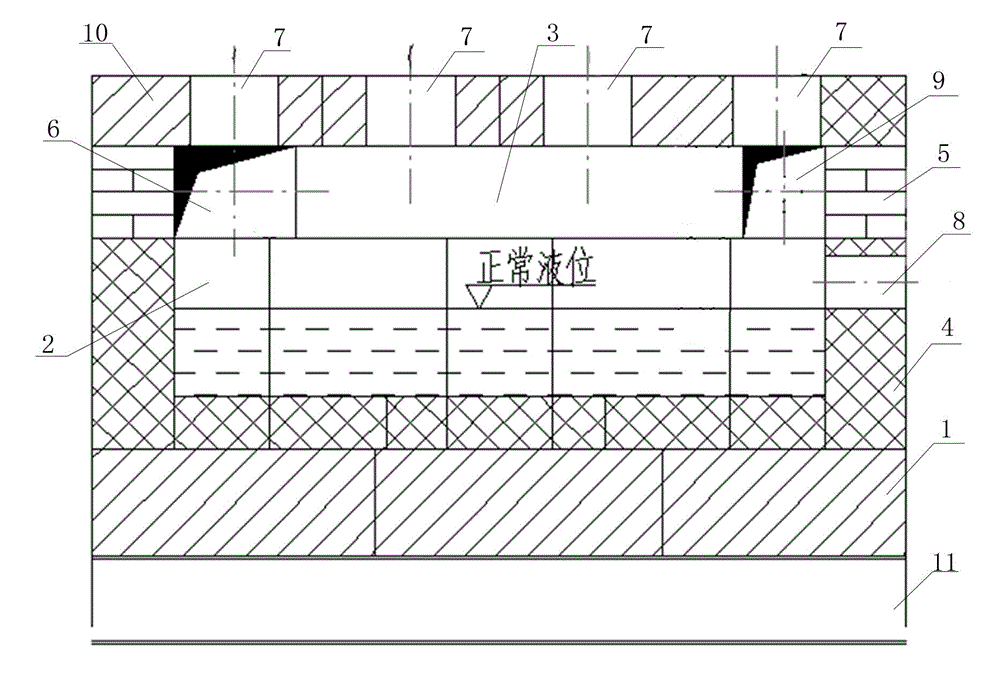

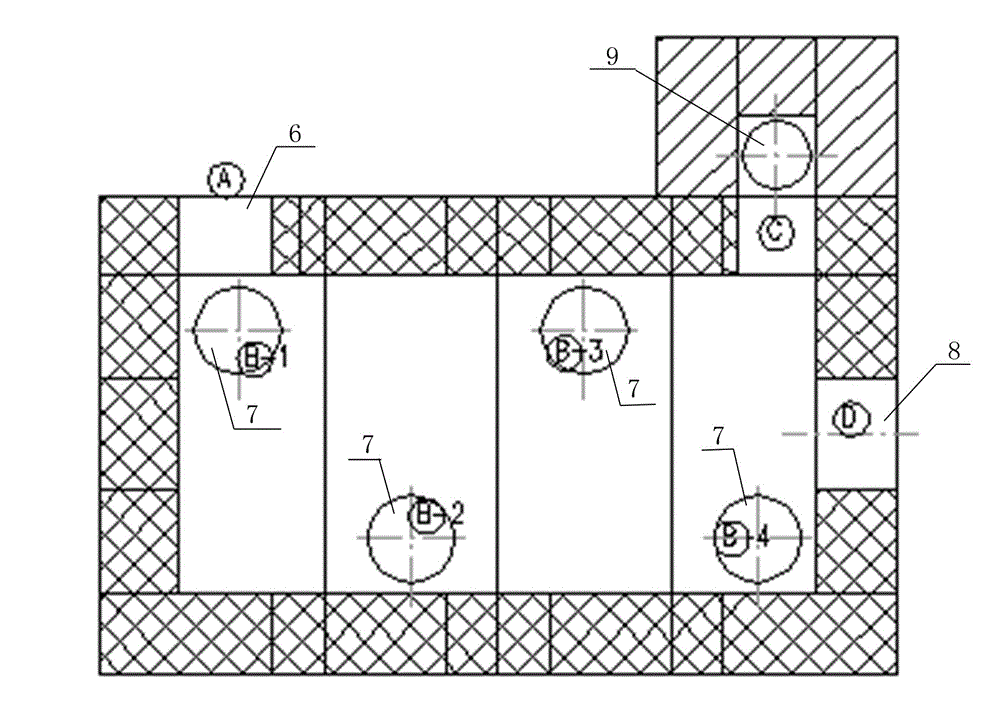

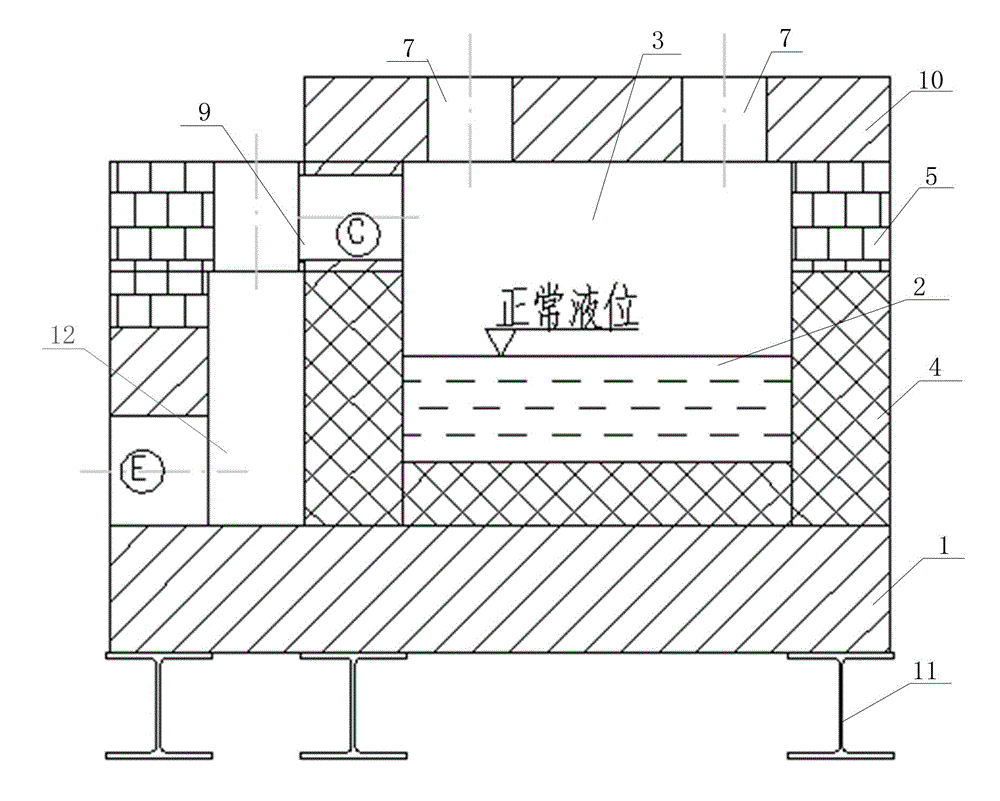

[0026] Such as figure 1 , figure 2 with image 3 As shown, the front view, top view and left side view of the melting furnace used for the recycling of by-product industrial salt according to the present invention are respectively provided, which includes a foundation 1, a melting chamber 2, a heating chamber 3, a feed port 6, a natural gas Nozzle interface 7, material outlet 8, flue gas outlet 9, top cover 10, base 11, flue soot cleaning port 12; the foundation 1 shown is set on the base 11, the melting chamber 2 is located above the foundation 1, and the base 11 Realize the fixing and supporting effect on the foundation 1. The melting chamber 2 is composed of refractory bricks 4, which can not only withstand the high temperature in the melting state of by-product industrial salt, but also avoid the phenomenon of "sticking to the wall". Above the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com