Adhesive film feeding mechanism

A feeding mechanism and film technology, applied in the directions of sending objects, thin material processing, lamination auxiliary operations, etc., can solve the problems of cutting loss, warpage and deformation of film materials, increase production costs, etc., to reduce the probability of occurrence, The effect of increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

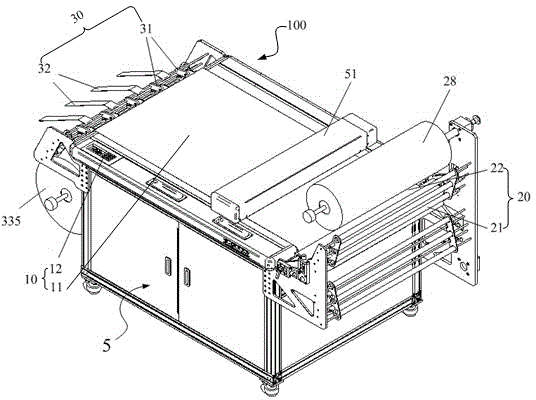

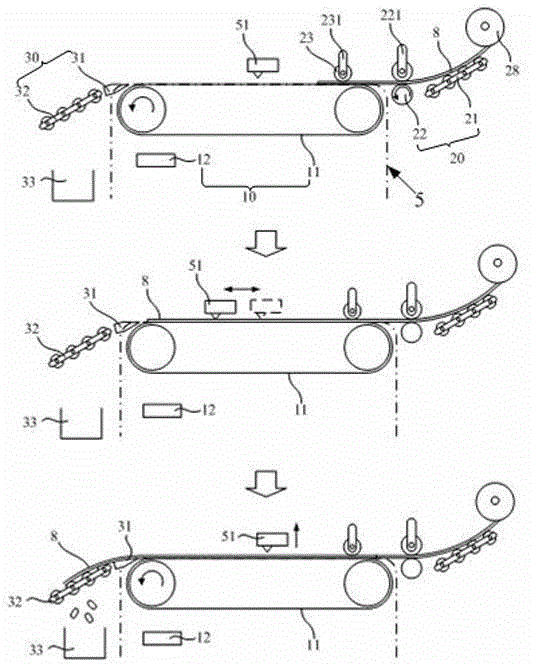

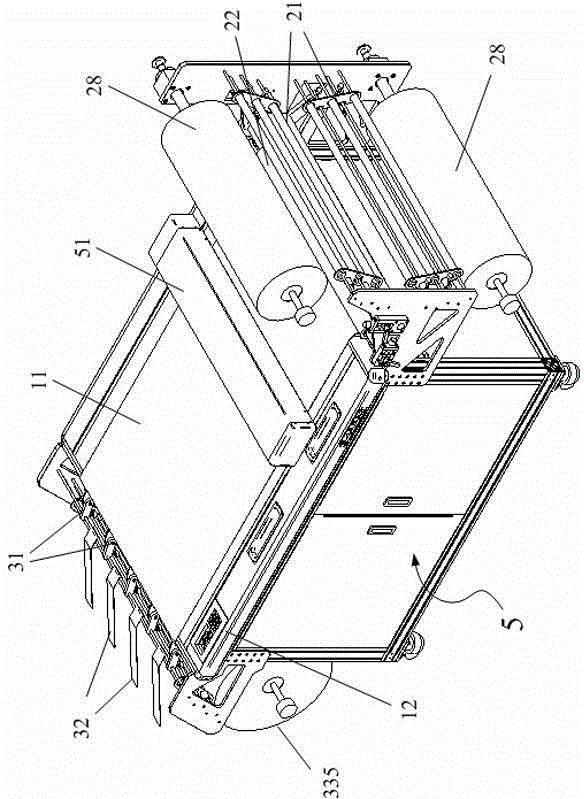

[0027] In order to make the objectives, technical solutions and effects of the present invention clearer and clearer, the present invention will be further described in detail below with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, but not to limit the present invention.

[0028] The advantages, features, and technical methods of the present invention will be described in more detail with reference to the exemplary embodiments and the accompanying drawings to make it easier to understand, and the present invention may be implemented in different forms, so it should not be understood to be limited to these The described embodiments, on the contrary, for those with ordinary knowledge in the technical field, the provided embodiments will make this disclosure more thorough, comprehensive and complete to convey the scope of the present invention, and the prese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com