Precisely-metering disc feeder, as well as liquid adding device and application thereof

A disc feeder, precise technology, applied in the field of machinery, can solve problems such as poor fluidity, unevenness, discontinuous material discharge, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

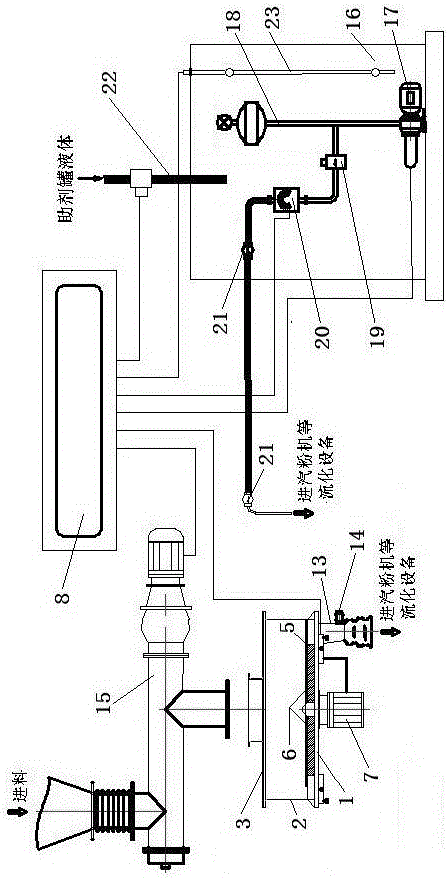

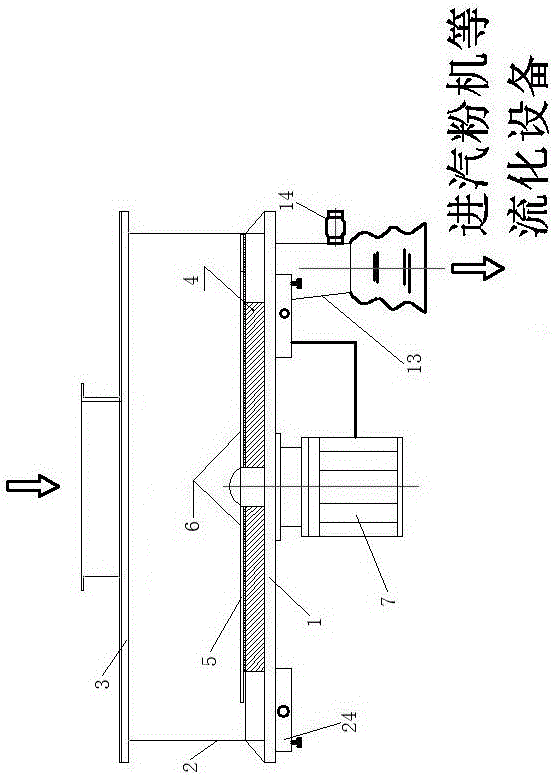

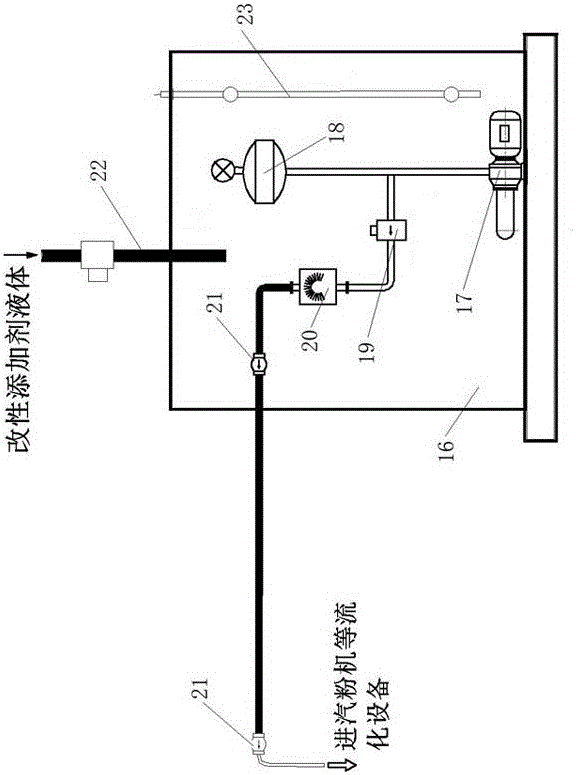

[0067] The device of this embodiment includes two parts: an accurate metering disc feeder and a liquid adding device. Accurate metering disc feeder includes bottom plate 1, side plate 2, top plate 3, fixed height fixing device 4, scraper plate 5 for holding materials, scraper plate 6, rotating drive device, connecting shaft, connected with the rotating drive device Control system 8, feeding device 15, discharge pipe 13, vibration source 14. Wherein, the cross-section of the side plate 2 along the horizontal direction is circular, the bottom plate 1, the side plate 2, and the top plate 3 are connected successively to form a cylindrical shell, and the top plate 3 is provided with a feeding port through which materials can be added, and the bottom plate 1 is provided with a discharge port 12 matching the material chamber; the discharge pipe 13 is connected to the discharge port 12, and the material can be accurately fed through the discharge pipe 13 after passing through the disc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com