Gene fusion reaction adhesion type wet-applied waterproof coiled material and method for constructing same

A gene fusion, waterproofing membrane technology, applied in chemical instruments and methods, building insulation materials, synthetic resin layered products, etc., can solve the problem of thermal stability, dimensional stability, two-way tear resistance, strength and problems such as low elongation, to achieve the effect of good compactness, excellent weather resistance and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the embodiments and accompanying drawings, but they are not limitations to the technical solution of the present invention, and any changes made based on the teachings of the present invention all fall within the scope of protection of the present invention.

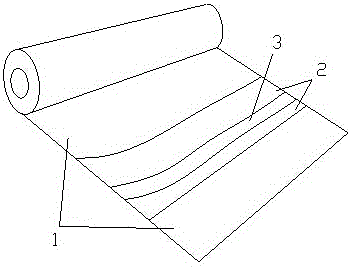

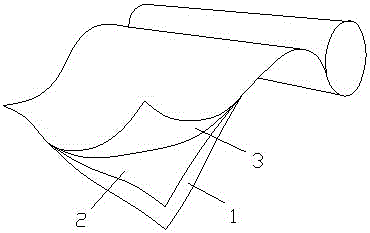

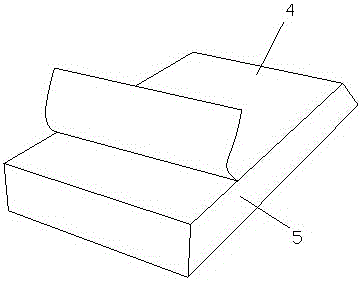

[0026] As shown in 1-2, a gene fusion reaction bonding wet-laid waterproof membrane includes a cross-laminated strength film 3, and the cross-laminated strength film 3 is made of cross-laminated high-density polyethylene films, The high-density polyethylene film is cross-laminated by single-layer films cut at 45° obliquely to form a multi-layer film. The outer surface of the cross-laminated strength film 3 is coated with a rubber asphalt self-adhesive material 2. Rubber asphalt self-adhesive material 2 is covered with silicone oil anti-adhesive isolation film 1. If only one side is required to stick to concrete 5, only one layer of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com