Processing method of microstructure array

A technology of microstructure arrays and processing methods, which is applied in the direction of metal processing equipment, electrochemical processing equipment, manufacturing tools, etc., can solve the problems of narrow application range of masks and complicated mask preparation, and achieve easy implementation and simple mask preparation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

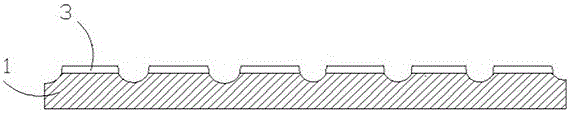

[0028] Combine below figure 1 , figure 2 , image 3 with Figure 4 The present invention is specifically illustrated for further description.

[0029] A processing method of a microstructure array of the present embodiment comprises the following steps:

[0030] (1) Take a certain amount of emulsified wax, atomize and evenly spray the emulsified wax on the surface 1 of the workpiece to be processed with atomization equipment, so that the atomized emulsified wax droplets 2 are discrete and evenly attached to the surface 1 of the workpiece to be processed superior.

[0031] The surface of the workpiece to be processed should be polished, degreased and derusted. Preferably, the material of the workpiece to be processed is a conductive material with good electrolytic machining performance, such as nickel, copper or stainless steel. The workpiece to be processed used in this example is a stainless steel sheet.

[0032] Preferably, the emulsifying wax adopts polypropylene wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com