A kind of processing method of glass fiber reinforced plastic parts

A processing method and glass fiber reinforced plastic technology, applied in the field of parts processing, can solve the problems of slag dropping around the opening of the glass fiber reinforced plastic, and achieve the effect of improving the processing effect and avoiding the slag dropping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The embodiments of the present invention provide a processing method for FRP parts, which solves the technical problem of slag falling in different parts around the FRP opening in the prior art, and achieves the technical effect of improving the processing effect.

[0031] The technical solution in the embodiment of the present invention is to solve the above-mentioned technical problems, and the general idea is as follows:

[0032] Taking the center of the R-shaped surface of the part to be processed as the dividing line, the R-shaped surface is divided into two parts for symmetrical processing, and the two ends of the processing are guaranteed to be flat. Slag, thereby improving the processing effect of parts.

[0033] In order to better understand the above technical solution, the above technical solution will be described in detail below in conjunction with the accompanying drawings and specific implementation methods.

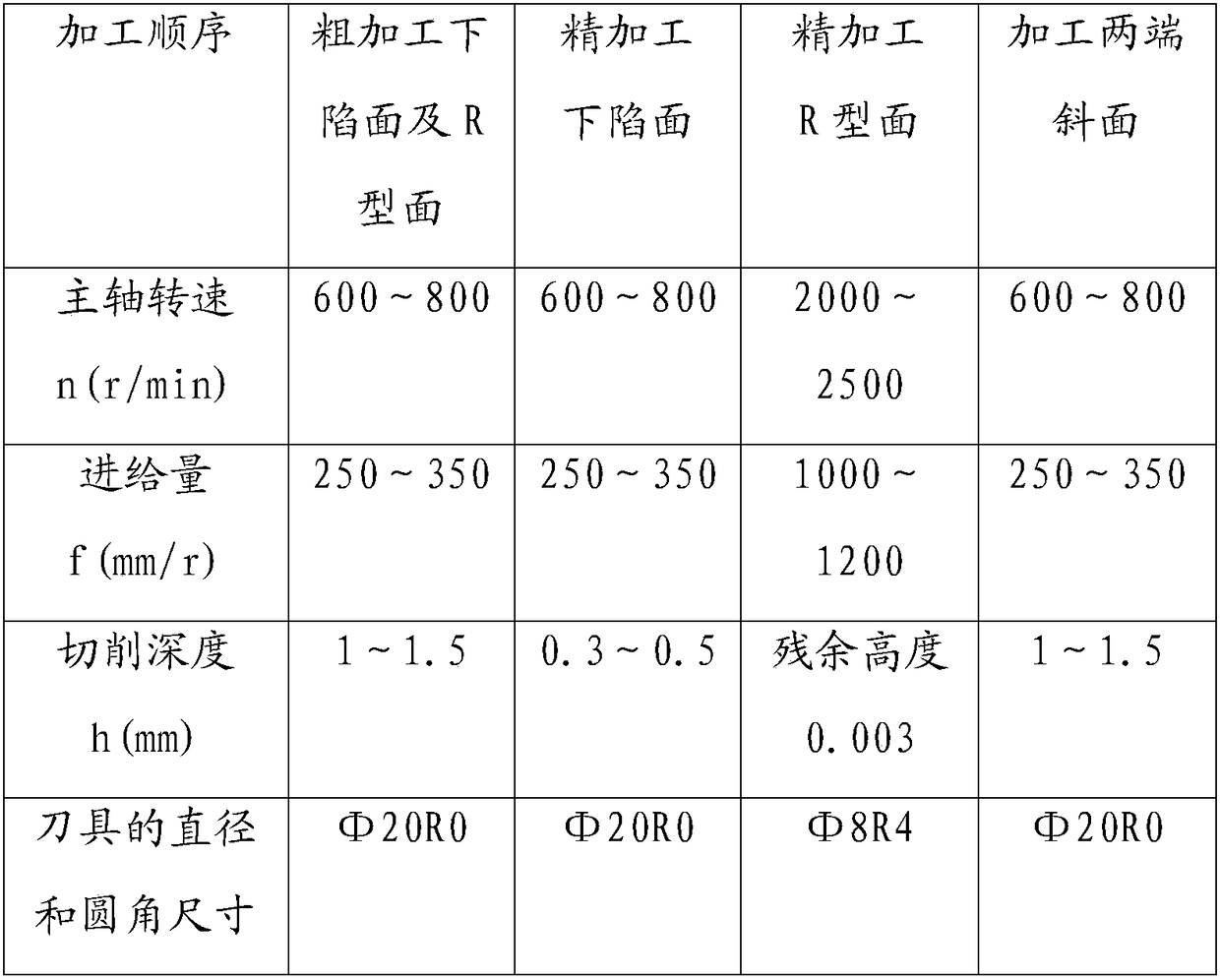

[0034] see figure 1 , the processing method...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com