Die cavity structure of back box body casing of wind power generating unit and method

A technology for wind turbines and rear boxes, which is applied in the casting field of castings, and can solve problems such as uneven filling, pore defects, and slag inclusion defects in castings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The new invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments; however, the following examples do not limit the present invention.

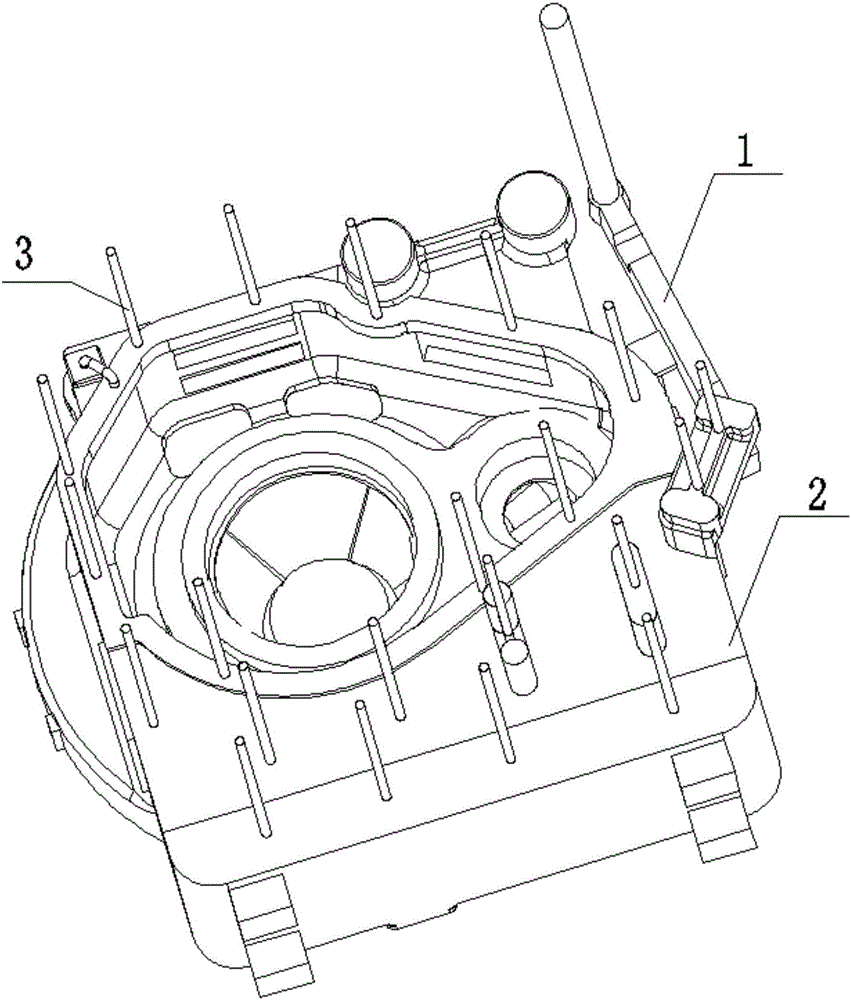

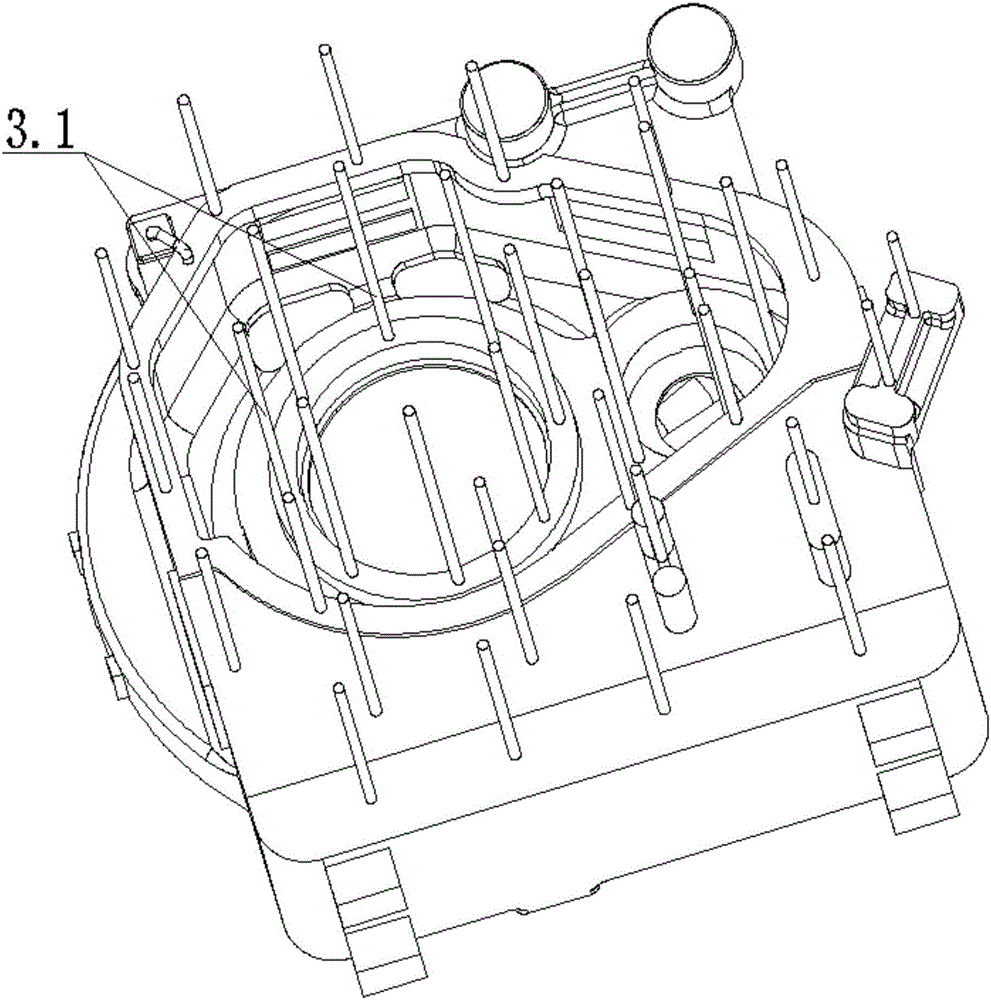

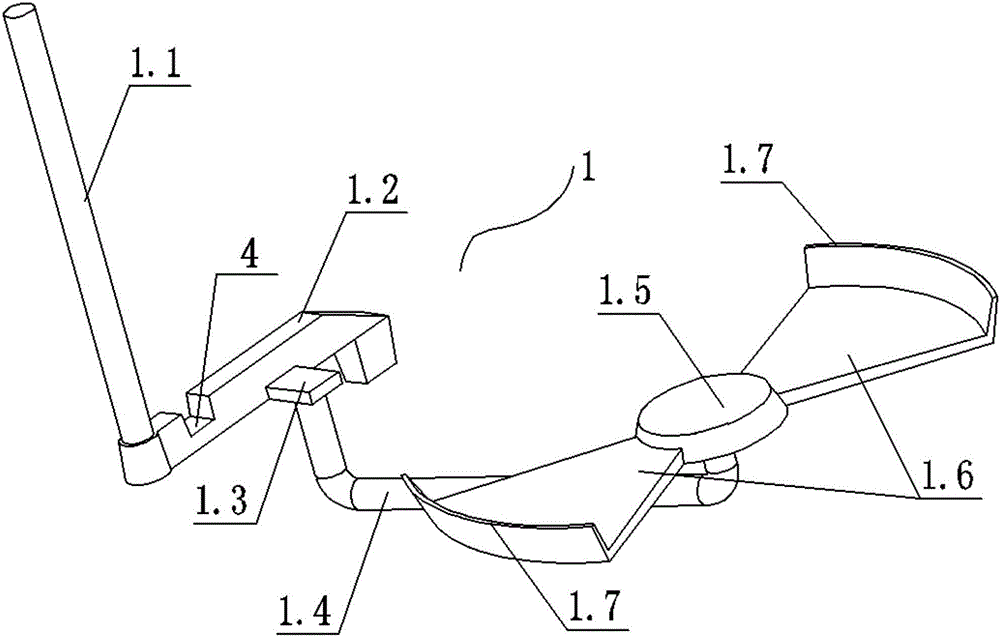

[0032] as attached Figure 1-3 As shown, as an embodiment: a cavity structure of a wind turbine rear box casting of the present invention, the structure includes a pouring system 1, a rear box cavity 2, and an air outlet 3 arranged on the rear box cavity The pouring system includes a sprue 1.1, a runner 1.2 connected with the sprue, and the runner is connected with a first transition runner 1.3, a second transition runner 1.4, and a third transition runner 1.5 in sequence. , the fourth transition runner 1.6; the fourth transition runner communicates with the rear box body cavity through the ingate 1.7; the first buffer runner 4 is arranged on the runner, and the cross-sectional area of the sprue is the same as The cross-sectional area ratio of the first buffer runner i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com