Laminator Pole Piece Cutting Device

A laminating machine and pole piece technology, which is applied to presses, punching machines, chemical instruments and methods, etc., can solve the problems of low punching efficiency and unqualified pole piece punching quality, etc. Fast speed, meet the effect of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with specific drawings.

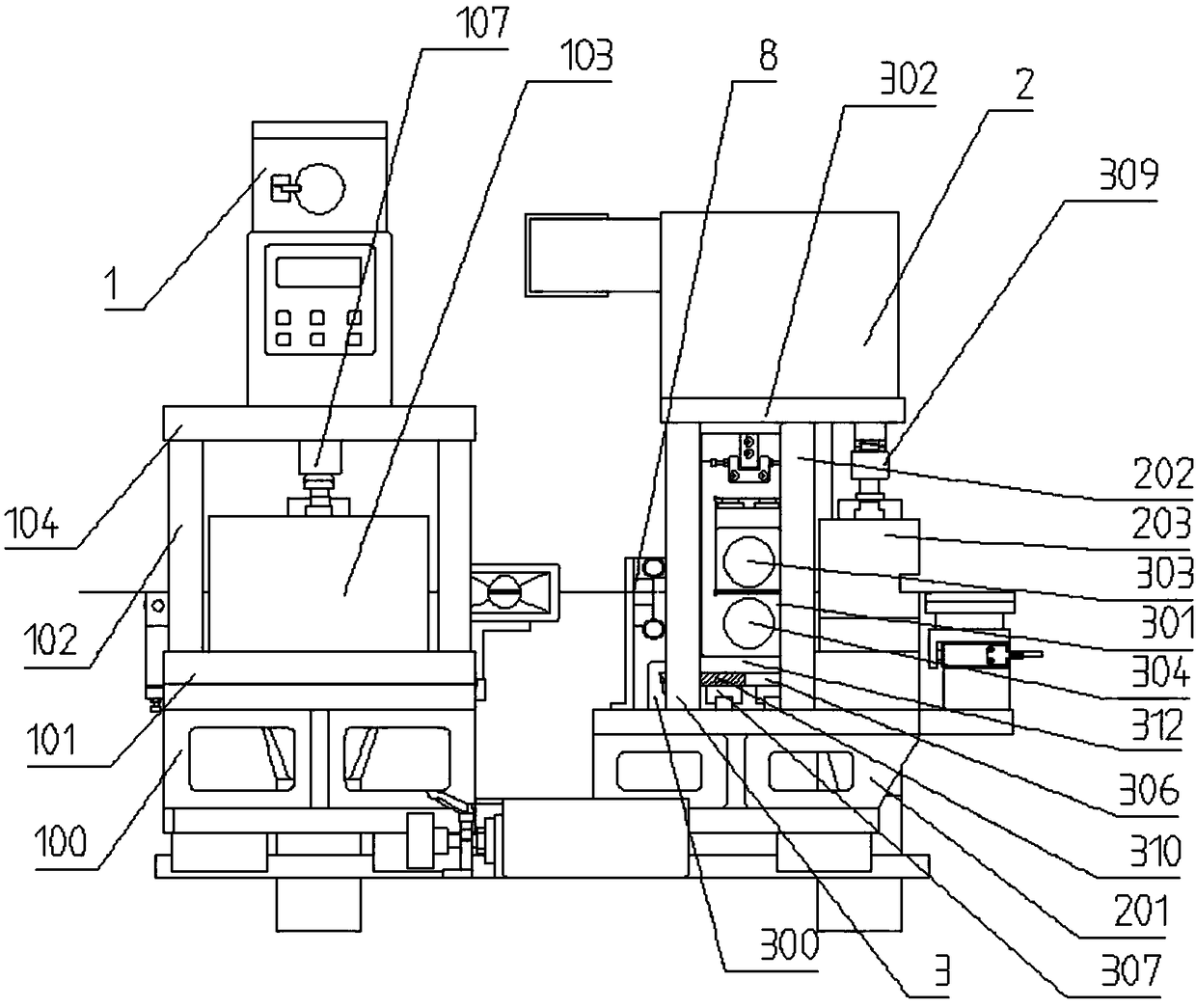

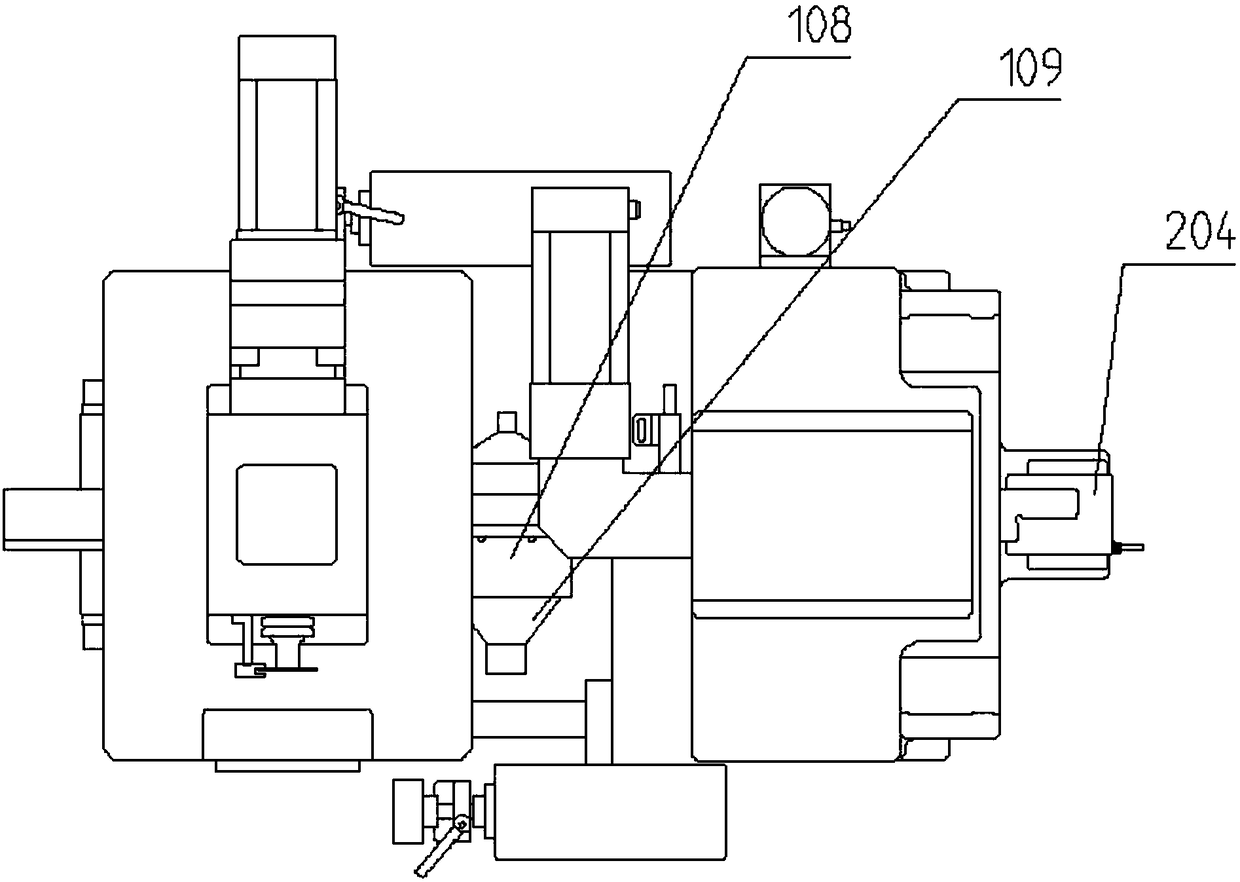

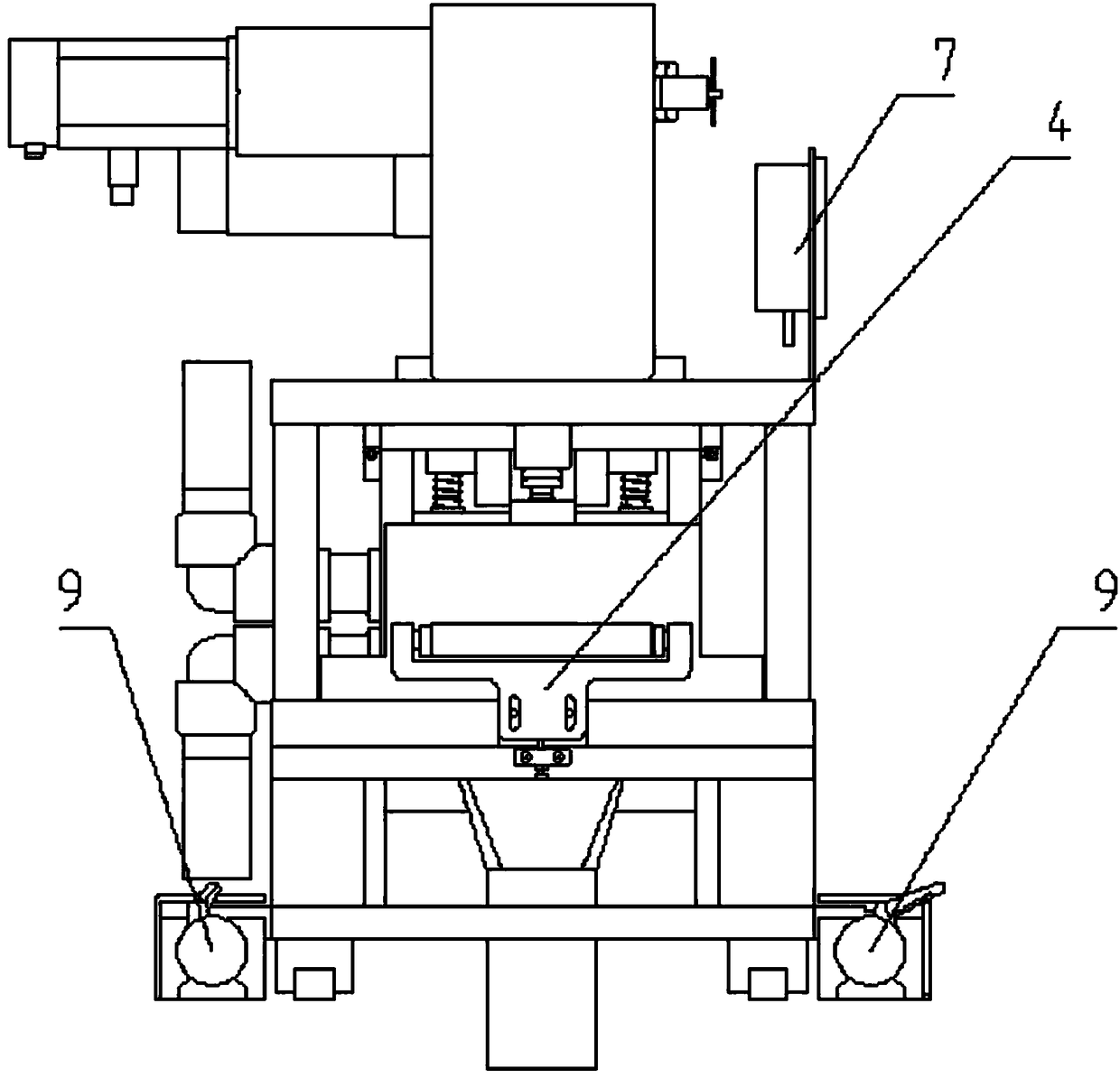

[0035] Such as Figure 1 to Figure 10 As shown: the pole piece punching device of the stacking machine includes a lug die stamping mechanism 1, a cutting die stamping mechanism 2, a main drive mechanism 3, a roller assembly 4, a guide post guide sleeve assembly 5, a cylinder 6, and a deviation correction controller 7 , Correction sensor 8, variety switching position adjustment mechanism 9, brush dust removal device 10, first support frame 100, mold bottom plate 101, first support column 102, anode forming mold 103, cutting mold top plate 104, crankshaft 105, connecting rod 106 , the first punch 107, the fixed block 108, the hopper 109, the connecting rod fixed block 110, the rail limit assembly 111, the second support frame 201, the second support column 202, the anode cutting die 203, the compensation motor 204, and the main drive deviation correction power Mechanism 300, su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com