Method for preparing dual-function catalyst and application thereof

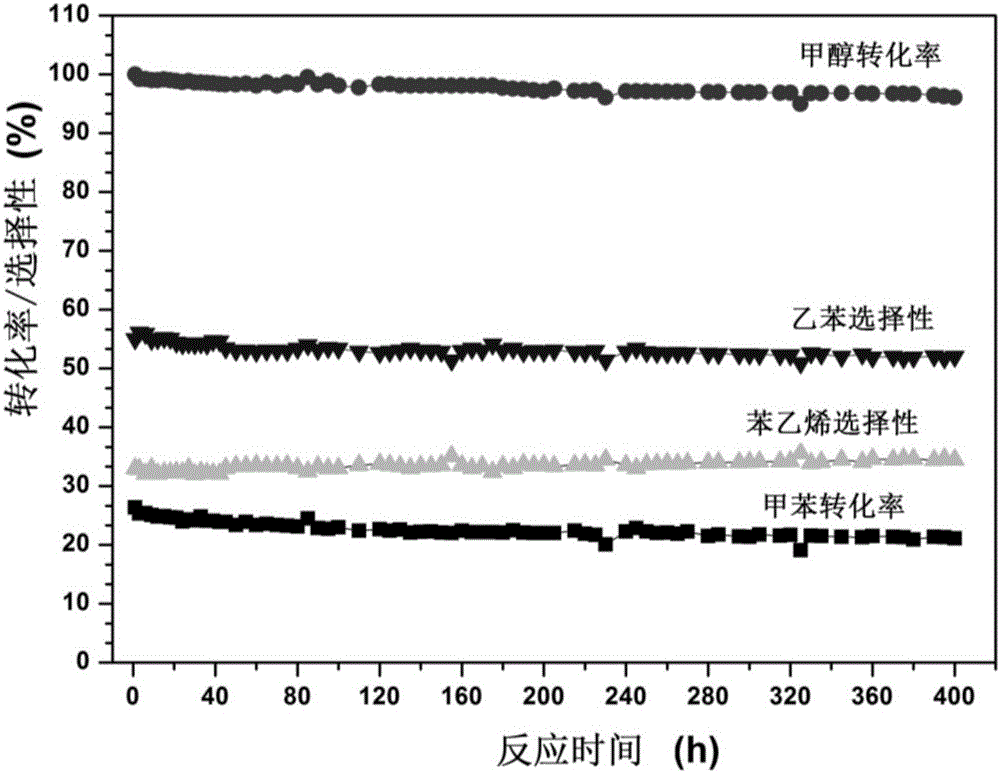

A dual-function catalyst and additive technology, applied in the chemical industry, can solve the problems of low utilization rate, low conversion rate of toluene, severe methanol decomposition, etc., achieve the effect of simple operation, simple preparation method, and meet the requirements of industrial application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] The preparation of embodiment 1 basic molecular sieve sample

[0055] Basic molecular sieve sample Z-1 # preparation of

[0056] Take 20 g each of NaX (Si / Al=1.17), NaY (Si / Al=2.51), and Naβ (Si / Al=3.93), and exchange them with 125 ml of 0.5 mol / L CsCl solution at 80°C for 4 times. Washing with deionized water and suction filtration until the filtrate was added with silver nitrate solution without precipitation, dried overnight at 120°C, roasted in the air at 500°C for 5 hours, after grinding, pressed into tablets, crushed and sieved into 20-40 mesh for later use, the obtained The sample is marked as Z-1 # ~Z-3 # .

[0057] Equal volume impregnated basic molecular sieve sample Z-4 # ~Z-8 # preparation of

[0058] First vacuumize the carrier to be impregnated, and then use deionized water to measure the saturated adsorption capacity of the carrier to deionized water. Calculate the mass of the impregnated precursor according to the load, dissolve the corr...

Embodiment 2

[0062] The preparation of embodiment 2 metal oxide samples

[0063] metal oxide OX-1 # Preparation of:

[0064] Take 7.9g Cu(NO 3 )·3H 2 O, 7.1g Zn(NO 3 ) 2 ·6H 2 O, 5.6g Al(NO 3 ) 3 9H 2 O, 1.3g Cr(NO 3 ) 3 9H 2 O was dissolved in 125ml deionized water, and under high-speed stirring at 70°C, 1mol / L Na 2 CO 3 The pH of the solution was adjusted to 7, aged at 80°C for 5 hours, filtered, dried overnight at 120°C, roasted at 520°C for 2 hours, ground, pressed into tablets, crushed and sieved into 20-40 mesh for later use. The obtained sample was designated as OX-1 # .

[0065] OX-2 # ~OX-3 # Preparation of:

[0066] The specific experimental steps are the same as OX-1 # The preparation of the metal salt, the relationship between the type and amount of the metal salt and the sample number are shown in Table 2.

[0067] Table 2

[0068]

Embodiment 3

[0069] The element composition analysis of embodiment 3 basic molecular sieve sample and metal oxide sample

[0070] Sample Z-1 by XRF # ~Z-8 # and sample OX-1 # ~OX~3 # The element composition of is analyzed, and the result is as shown in table 3 and table 4:

[0071] table 3

[0072]

[0073] Table 4

[0074] sample Molar ratio of metal elements OX-1 # Cu: Zn: Al: Cr: = 10.4: 7.9: 4.4: 1 OX-2 # Cu: Zn: Al: Cr: = 9.7: 5.5: 4.1: 1 OX-3 # Cu: Zn: Al: Cr: = 14.8: 3.8: 2.7: 1

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com