Lotus-root-shaped porous carbon/oxyhalogen bismuth semiconductor composite photocatalysis material as well as preparation and application thereof

A composite photocatalysis, porous carbon technology, applied in catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of weak visible light activity, large forbidden band width, low quantum efficiency, etc. Low cost, good stability and strong catalytic ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

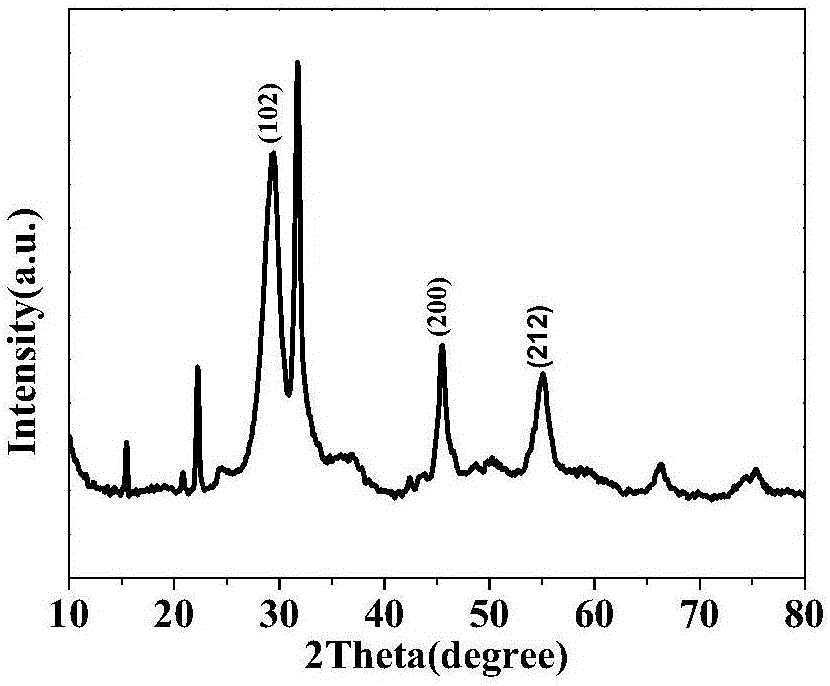

Embodiment 1

[0057] 1. Material preparation:

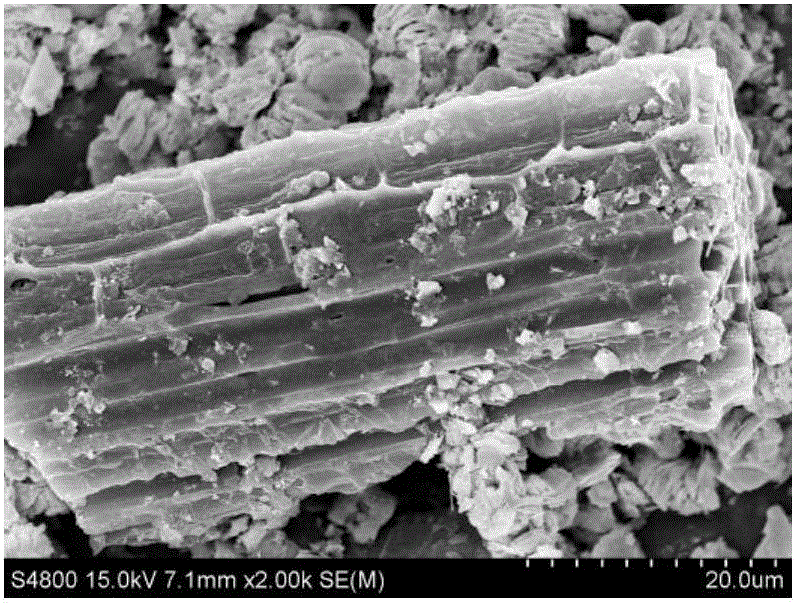

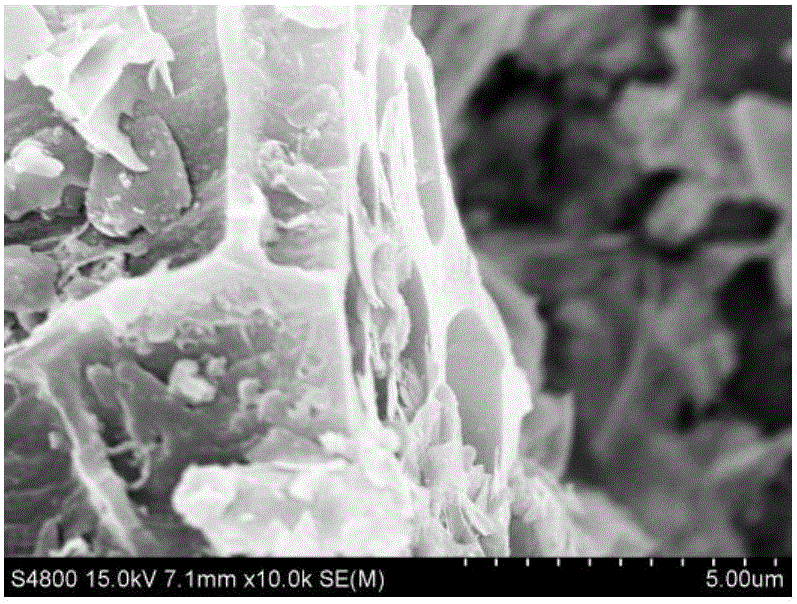

[0058] (1) The air-dried cattail grass is placed in a tube furnace and carbonized for a period of time under the protection of inert gas. The black powder collected after cooling is the lotus root-like porous carbon.

[0059] (2) Add 36mg of lotus root-like porous carbon to a 20ml mixture of ethanol and ethylene glycol in a beaker and stir for 30 minutes (including 8ml of ethanol and 12ml of ethylene glycol), and then add 3m mol (1.4553g) of Bi(NO) 3 ) 3 ·5H 2 O, marked as solution 1; meanwhile, 3m mol of KI (0.4980g) was dissolved in 20ml of ethanol and ethylene glycol mixed solution (of which 8ml of ethanol, 12ml of ethylene glycol), recorded as solution 2;

[0060] (3) Solutions 1 and 2 were quickly stirred at room temperature for 30 minutes; the stirred solution 2 was quickly added to solution 1, and quickly stirred at room temperature for 60 minutes;

[0061] (4) Load the above-mentioned mixed liquid into a microwave reactor and perform microwave ...

Embodiment 2

[0076] Material preparation: (1) Air-dried cattail grass is placed in a tube furnace and carbonized for a period of time under the protection of inert gas. The black powder collected after cooling is lotus root-like porous carbon.

[0077] (2) Add 36mg of lotus root-like porous carbon to a 20ml mixture of ethanol and ethylene glycol in a beaker and stir for 30 minutes (including 8ml of ethanol and 12ml of ethylene glycol), and then add 3m mol (1.4553g) of Bi(NO) 3 ) 3 ·5H 2 O, marked as solution 1; meanwhile, 3m mol of KBr (0.3570g) was dissolved in 20ml of ethanol and ethylene glycol mixed solution (of which 8ml of ethanol, 12ml of ethylene glycol), recorded as solution 2;

[0078] (3) Solutions 1 and 2 were quickly stirred at room temperature for 30 minutes; the stirred solution 2 was quickly added to solution 1, and quickly stirred at room temperature for 60 minutes;

[0079] (4) Load the above-mentioned mixed liquid into a microwave reactor and perform microwave reaction at 600W f...

Embodiment 3

[0090] (1) The air-dried cattail grass is placed in a tube furnace and carbonized for a period of time under the protection of inert gas. The black powder collected after cooling is the lotus root-like porous carbon.

[0091] (2) Add 36mg of lotus root-like porous carbon to a 20ml mixture of ethanol and ethylene glycol in a beaker and stir for 30 minutes (including 8ml of ethanol and 12ml of ethylene glycol), and then add 3m mol (1.4553g) of Bi(NO) 3 ) 3 ·5H 2 O, marked as solution 1; at the same time, 1.5m mol of KI (0.2490g) and 1.5m mol of KBr (0.1785g) were dissolved in 20ml of ethanol and ethylene glycol mixed solution (including 8ml of ethanol and 12ml of ethylene glycol), Recorded as solution 2;

[0092] (3) Solutions 1 and 2 were quickly stirred at room temperature for 30 minutes; the stirred solution 2 was quickly added to solution 1, and quickly stirred at room temperature for 60 minutes;

[0093] (4) Load the above mixed liquid into a microwave reactor and perform microwav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com