Nitrile rubber selective heterogeneous hydrogenation catalyst and preparation method and hydrogenation method thereof

A nitrile rubber, selective technology, applied in the direction of catalyst carrier, chemical instrument and method, metal/metal oxide/metal hydroxide catalyst, etc. Utilization and other issues to achieve the effect of high recycling efficiency, controllable particle size, and improved accessibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

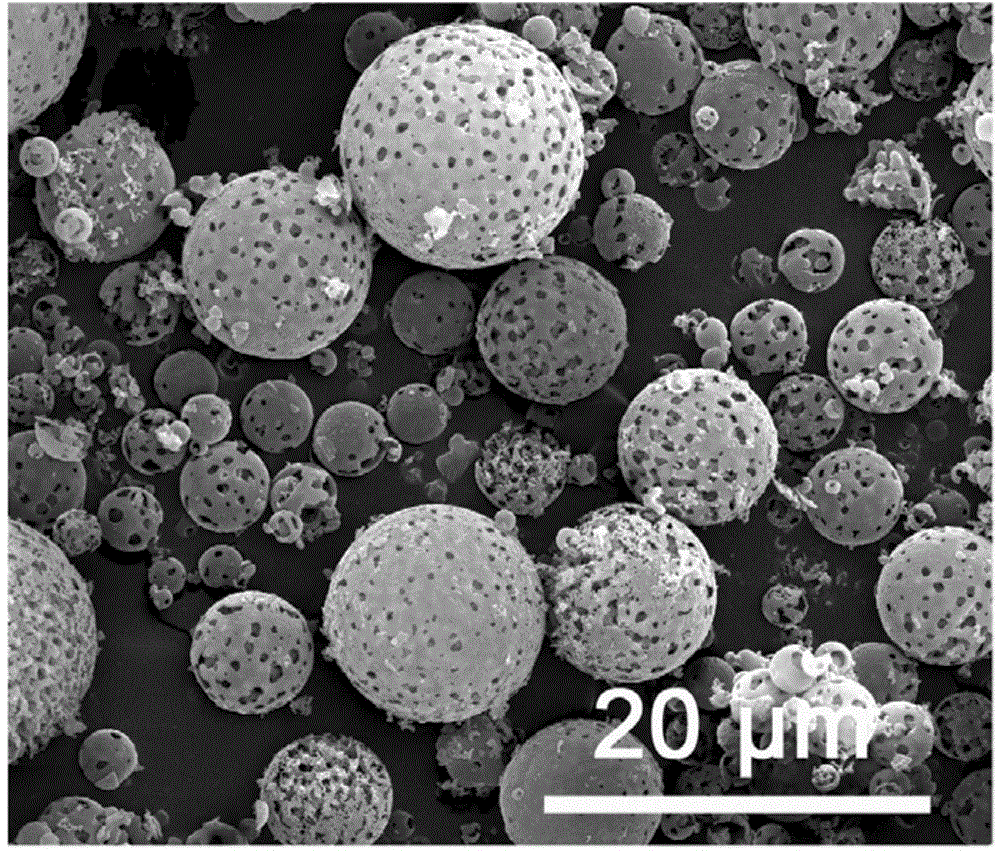

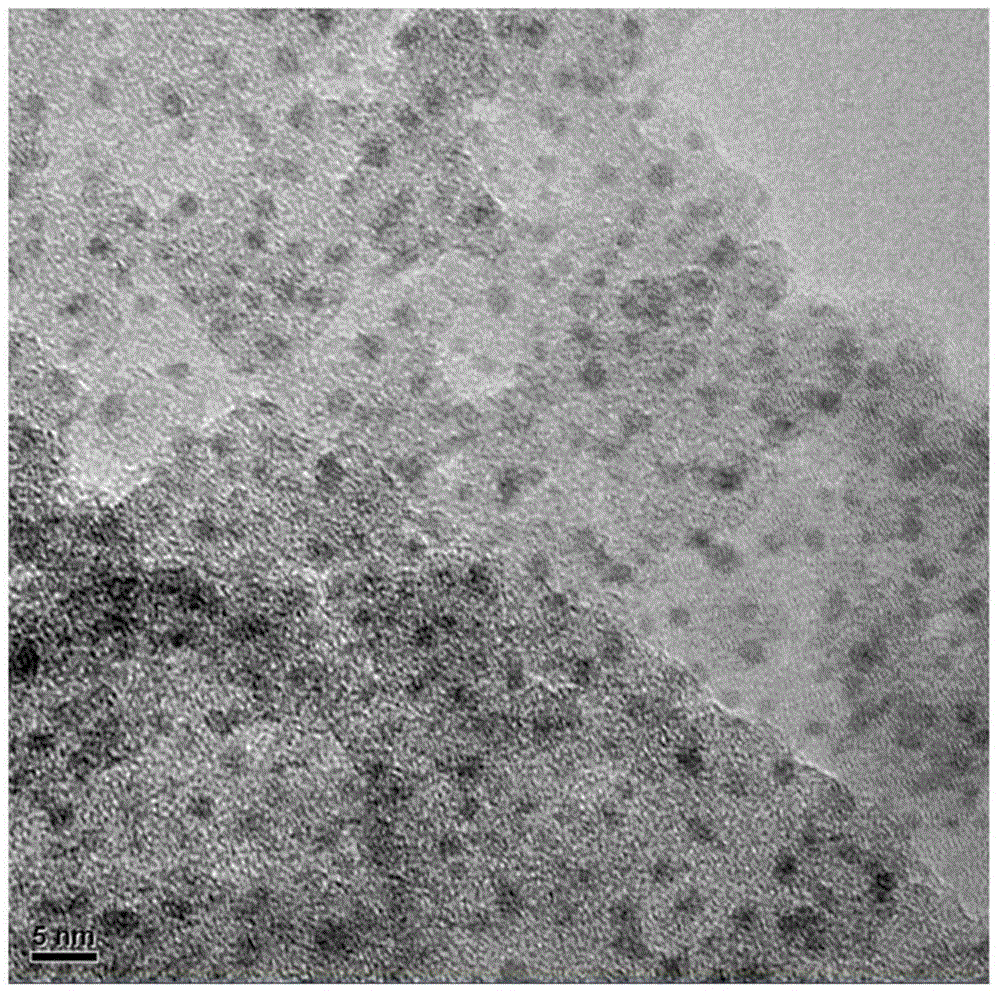

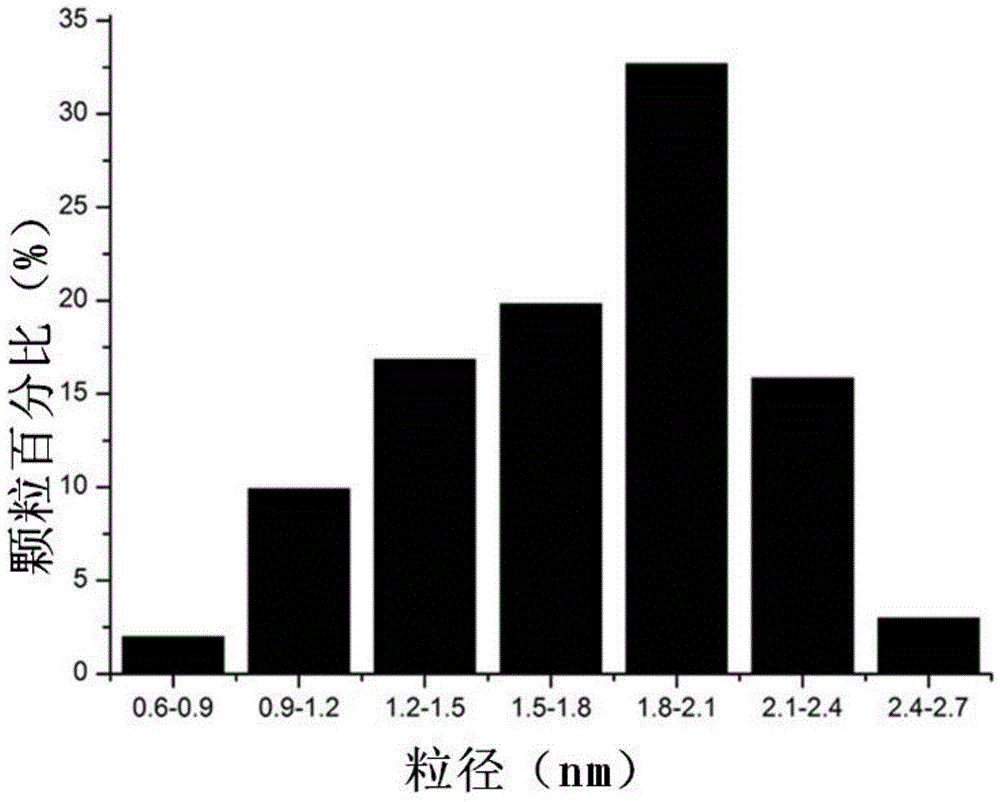

[0057] The present embodiment provides a kind of nitrile rubber selective heterogeneous hydrogenation catalyst, which is prepared through the following steps:

[0058] N-(beta-aminoethyl)-gama-aminopropyltrimethoxysilane was used as the coupling agent, the carrier SHMs was used as the carrier, and Pd(OAc) 2 The solution is a precursor solution, and N-(beta-aminoethyl)-gama-aminopropyltrimethoxysilane is used to functionalize the carrier SHMs to obtain the modified carrier SHMs; the modified carrier SHMs and Pd(OAc) 2 The solutions were mixed for reaction, and the heterogeneous catalyst Pd / SHMs with a loading capacity of 5% was prepared.

[0059] Present embodiment also provides the method for selective heterogeneous phase hydrogenation of nitrile rubber, the method may further comprise the steps:

[0060] Dissolve 2g of nitrile rubber (NBR) in 100mL of acetone solvent to obtain a glue solution. Take 2g of the above-mentioned heterogeneous catalyst Pd / SHMs and add it to the gl...

Embodiment 2

[0062] The present embodiment provides a kind of nitrile rubber selective heterogeneous hydrogenation catalyst, which is prepared through the following steps:

[0063] The carrier SHMs was functionalized with mercaptopropyltrimethoxysilane, and PdCl 2 The solution is a precursor solution, and a heterogeneous catalyst Pd / SHMs with a loading capacity of 5% is prepared.

[0064] Present embodiment also provides the method for selective heterogeneous phase hydrogenation of nitrile rubber, the method may further comprise the steps:

[0065] Dissolve 2g of nitrile rubber (NBR) in 100mL of acetone solvent to obtain a glue solution. Take 2g of the above-mentioned heterogeneous catalyst Pd / SHMs and add it to the glue solution. At 80°C and a hydrogen pressure of 6MPa, hydrogenation reaction under high pressure Catalytic hydrogenation reaction was carried out in the kettle for 5h. After the reaction, the heterogeneous catalyst is centrifuged and recovered for reuse, and the liquid is e...

Embodiment 3

[0067] The present embodiment provides a kind of nitrile rubber selective heterogeneous hydrogenation catalyst, which is prepared through the following steps:

[0068]Carrier SHMs were functionalized with N-(beta-aminoethyl)-gama-aminopropyltrimethoxysilane, utilizing Pd(OAc) 2 The solution is a precursor solution, and a heterogeneous catalyst Pd / SHMs with a loading of 4% is prepared.

[0069] Present embodiment also provides the method for selective heterogeneous phase hydrogenation of nitrile rubber, the method may further comprise the steps:

[0070] Dissolve 2g of nitrile rubber (NBR) in 100mL of acetone solvent to obtain a glue solution. Take 2g of the above-mentioned heterogeneous catalyst Pd / SHMs and add it to the glue solution. At 80°C and a hydrogen pressure of 6MPa, hydrogenation reaction under high pressure Catalytic hydrogenation reaction was carried out in the kettle for 5h. After the reaction, the heterogeneous catalyst is centrifuged and recovered for reuse, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com