Reaction equipment for synthesizing D-phenylglycine methyl ester hydrochloride

A technology of phenylglycine methyl ester and reaction equipment, which is applied in the field of reaction equipment for the synthesis of D-phenylglycine methyl ester hydrochloride, which can solve the problems of oversized equipment, difficult sampling, and location at the bottom of the equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

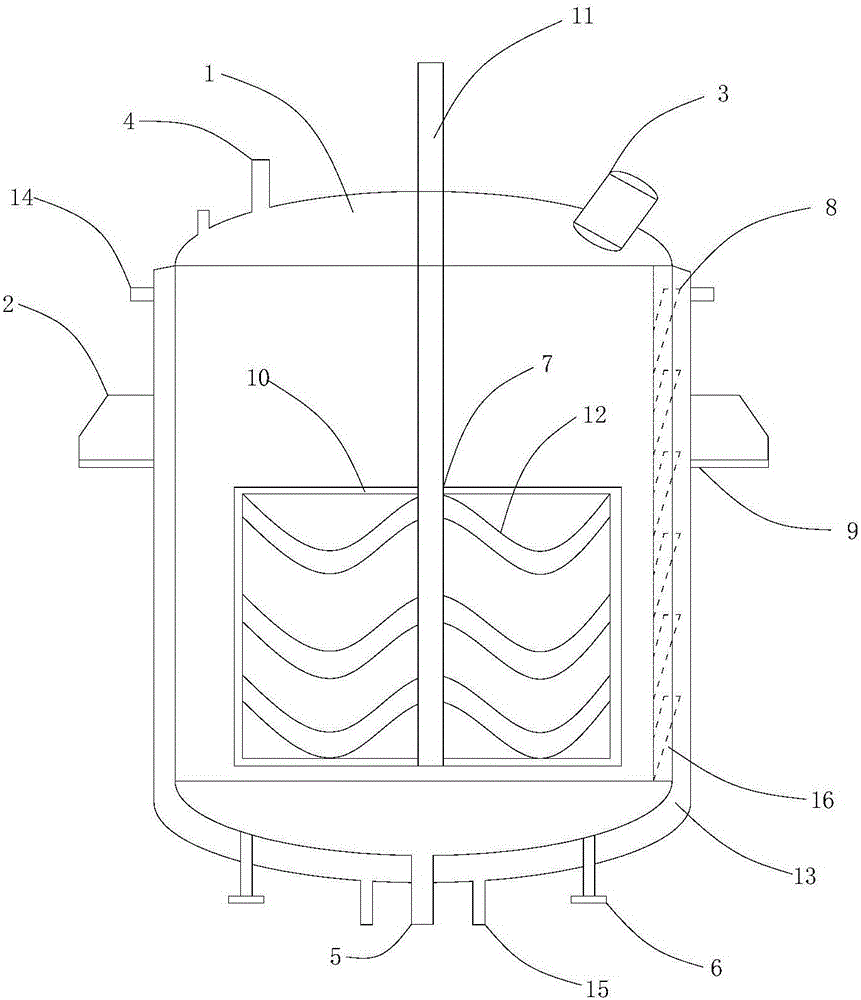

[0022] A kind of reaction equipment for the synthesis of D-phenylglycine methyl ester hydrochloride, comprising a kettle body 1, an ear seat 2 arranged on the kettle body 1, an observation port 3, a feed port 4, a discharge port 5 and a heating pipe 6, the kettle body Stirring device 7 is arranged inside 1, and a plurality of sampling tubes 8 are arranged on the outer wall of kettle body 1, and sampling tube 8 is outwardly inclined at 15-45°, and the sampling outlet of each sampling tube 8 is higher than the previous sampling tube 8 and the kettle. body 1 junction. The sampling tube is set on the kettle body, and the corresponding sampling tube can be opened according to the height of the reactor body where the reactants are located, and sampling can be performed quickly.

Embodiment 2

[0024] A kind of reaction equipment for the synthesis of D-phenylglycine methyl ester hydrochloride, comprising a kettle body 1, an ear seat 2 arranged on the kettle body 1, an observation port 3, a feed port 4, a discharge port 5 and a heating pipe 6, the kettle body Stirring device 7 is arranged inside 1, and a plurality of sampling tubes 8 are arranged on the outer wall of kettle body 1, and sampling tube 8 is outwardly inclined at 15-45°, and the sampling outlet of each sampling tube 8 is higher than the previous sampling tube 8 and the kettle. body 1 junction. The sampling tube is set on the kettle body, and the corresponding sampling tube can be opened according to the height of the reactor body where the reactants are located, and sampling can be performed quickly. A gravity sensor 9 is arranged under the ear socket 2 . The setting of the gravity sensor can accurately measure the weight of the reactant and provide the purity of the reaction composition.

Embodiment 3

[0026] A kind of reaction equipment for the synthesis of D-phenylglycine methyl ester hydrochloride, comprising a kettle body 1, an ear seat 2 arranged on the kettle body 1, an observation port 3, a feed port 4, a discharge port 5 and a heating pipe 6, the kettle body Stirring device 7 is arranged inside 1, and a plurality of sampling tubes 8 are arranged on the outer wall of kettle body 1, and sampling tube 8 is outwardly inclined at 15-45°, and the sampling outlet of each sampling tube 8 is higher than the previous sampling tube 8 and the kettle. body 1 junction. The sampling tube is set on the kettle body, and the corresponding sampling tube can be opened according to the height of the reactor body where the reactants are located, and sampling can be performed quickly. A gravity sensor 9 is arranged under the ear socket 2 . The setting of the gravity sensor can accurately measure the weight of the reactant and provide the purity of the reaction composition. The stirring d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com