Quaternized chitosan/polyacrylic acid composite nanofiltration membrane and preparation method thereof

A technology of quaternized chitosan and composite nanofiltration membrane, which is applied in the field of membrane separation, can solve the problems of weak positive charge and low flux, achieve good acid resistance and alkali resistance, good antibacterial effect, good The effect of interception effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

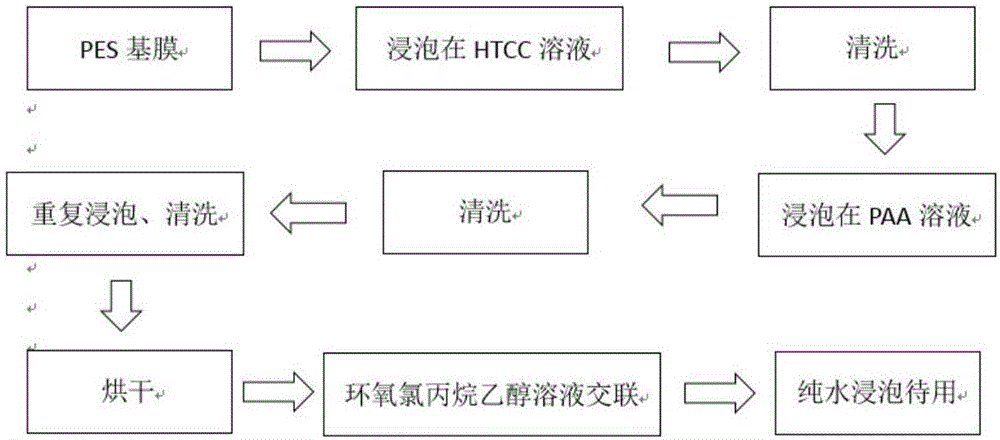

Method used

Image

Examples

Embodiment 1

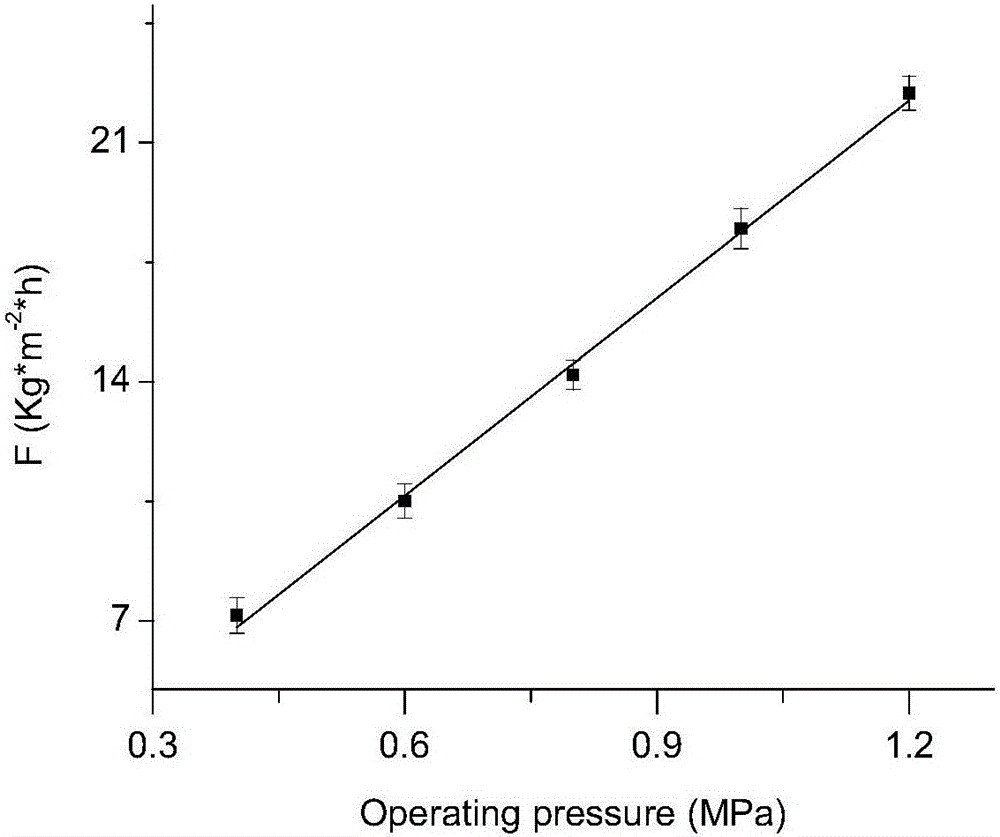

[0023] Prepare a 5g / L HTCC solution and a 1g / L PAA solution, adjust the pH of the PAA solution to 4, 7, and 10 with NaOH solution, and add NaCl as a supporting salt to the HTCC solution and PAA solution to make the NaCl concentration 0.05 g / L HTCC casting solution and PAA casting solution. Soak three PES base films in HTCC casting solution for 15 min, wash them with pure water to obtain composite films with positive charges on the surface; After washing with water, a composite film with a negatively charged surface is obtained, completing a double layer. The soaking was repeated to obtain a composite membrane with 4.5 double layers. Then, soak the three dry films in the ethanol solution of epichlorohydrin adjusted by KOH, pH 9, mass concentration 1.3%, cross-linking reaction at 50°C for 21 hours, after the cross-linking reaction is completed, dry, and remove Wash with deionized water, soak in pure water for more than 24 hours, and wait for determination.

[0024] The prepar...

Embodiment 2

[0026] Prepare a 5g / L HTCC solution, then take quantitative PAA and prepare 0.5g / L, 1g / L, 1.5g / L, 2g / L, 2.5g / LPAA solutions with pure water, and adjust the pH of the PAA solution to 7. Add NaCl as a supporting salt to the HTCC and PAA solutions respectively to prepare HTCC casting solutions and PAA casting solutions with a NaCl mass concentration of 0.05 g / L. Soak 5 pieces of PES base films in HTCC casting solution for 15 minutes, wash them with pure water to obtain composite films with positive charges on the surface; After washing, a composite film with a negatively charged surface is obtained, completing a double layer. The soaking was repeated to obtain a composite membrane with 4.5 double layers. Then, 5 pieces of dry films were respectively soaked in the ethanol solution of epichlorohydrin with pH 9 and mass concentration of 1.9% mediated by KOH, and cross-linked at 50°C for 21 hours. After the cross-linking reaction was completed, they were dried and removed Wash with...

Embodiment 3

[0029] Take quantitative HTCC and prepare 4g / L, 5g / L, 6g / L HTCC solutions with pure water respectively, prepare 1g / LPAA solution, adjust the pH of PAA solution to 7 with NaOH solution, and then add NaCl to HTCC and PAA solutions respectively As supporting salt, HTCC casting solution and PAA casting solution with NaCl mass concentration of 0.05g / L were prepared. Soak three PES base films in HTCC casting solution for 15 minutes, wash them with pure water to obtain composite films with positive charges on the surface; After washing, a composite film with a negatively charged surface is obtained, completing a double layer. The soaking was repeated to obtain a composite membrane with 4.5 double layers. Then, soak the three dry films in the ethanol solution of epichlorohydrin with a pH of 9 and a mass concentration of 2.5% mediated by KOH, and conduct a cross-linking reaction at 50°C for 21 hours. After the cross-linking reaction is completed, dry and remove Wash with deionized wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com