Integrated dust-fog removing device and dust-fog removing method for wet desulphurization system

A technology of wet desulfurization and wire mesh demister, which is applied in the direction of chemical instruments and methods, combined devices, separation devices, etc., can solve the problems of poor performance of demisters, single type of demisters, poor corrosion resistance of materials, etc. problems, to achieve the effect of easy installation, simple operation, and compact device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

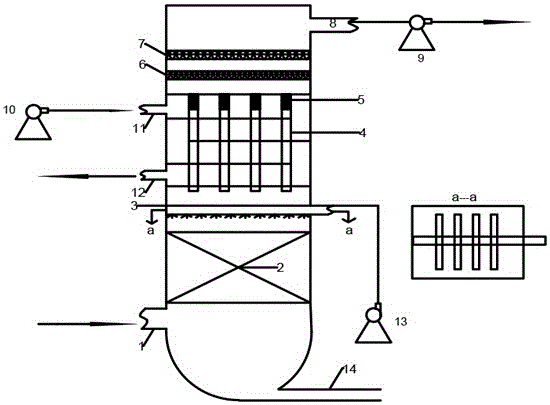

[0018] Combine below figure 1 The present invention is described in further detail with specific examples.

[0019] The dust removal-fog integrated device used in the wet desulfurization system of this embodiment, wherein the wet desulfurization system includes a flue gas inlet pipe 1, a desulfurization packing layer 2, a pipe sprayer 3 and a waste liquid drainage pipe 14 , the pipe sprayer 3 is connected with the plunger pump 13, the desulfurization packing layer 2 is located under the pipe sprayer 3, the flue gas inlet pipe 1 is arranged under the desulfurization packing layer 2, and the bottom of the whole wet desulfurization system is provided with Waste liquid drain pipe 14;

[0020] The dust removal-fog integrated device includes a condensing glass tube 4, PTFE demisting velvet 5, a primary PFTE wire mesh demister 6 and a secondary PFTE wire mesh demister 7; wherein the condensing glass tube 4 top The nozzle is filled with PTFE defogging velvet 5, and the condensation ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com