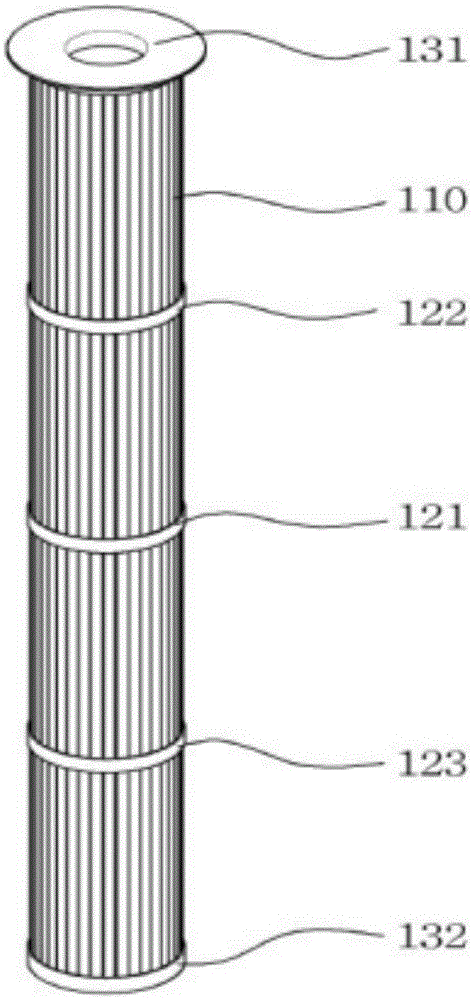

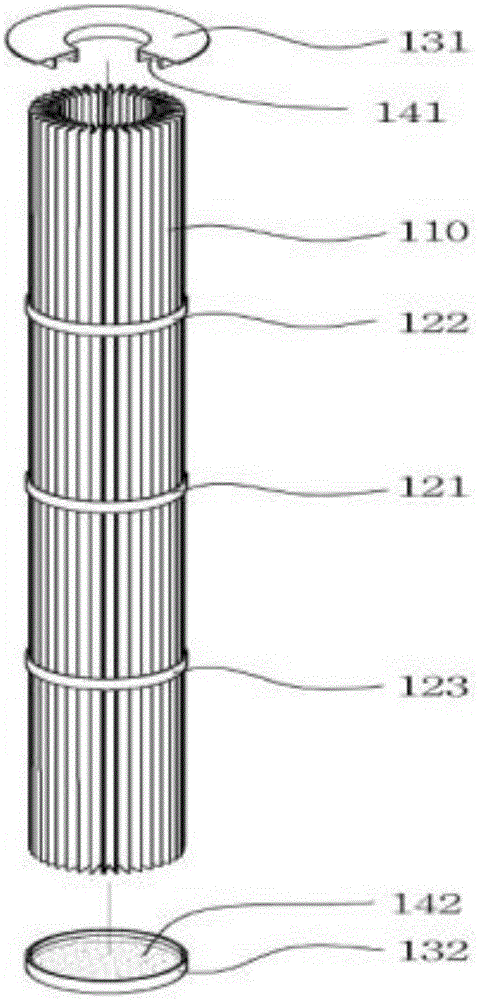

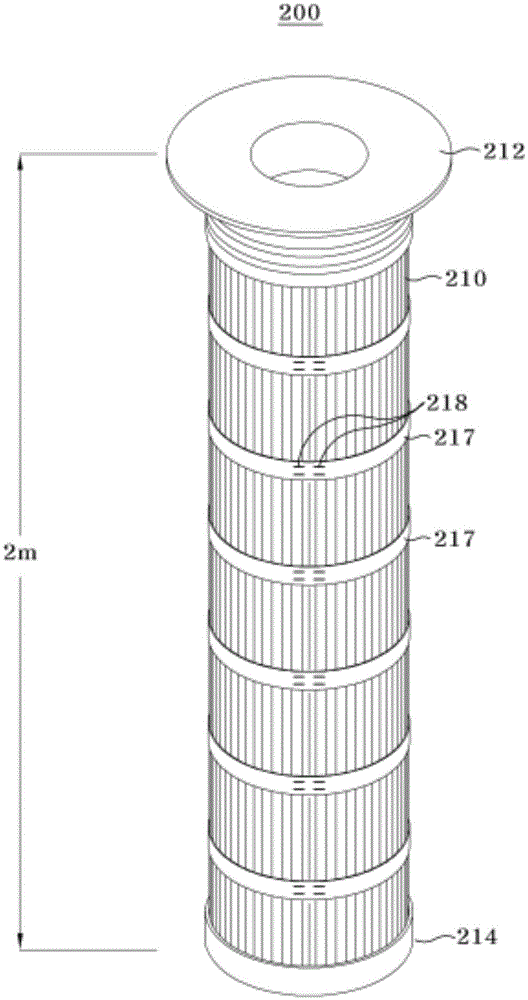

A fold type filter and a method for manufacturing the same

A manufacturing method and filter technology, which is applied to chemical instruments and methods, separation methods, and dispersed particle filtration, etc., can solve the problems that the filter function cannot be performed normally, and it is difficult to maintain the distance between multiple pleated peaks, etc., so as to reduce the processing cost , prevent deformation, handle simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0105] The weight of polyaramide (Polyaramide) is made into 150g / m by spunlace method 2 , a thickness of 1.0㎜, a tensile strength of 50㎏ / 5㎝ (cut strip method), an elongation of 25%, and a deviation of 20% in the left and right tensile strength of the non-woven fabric, relative to the impregnated 100 weight % of the non-woven fabric was impregnated with 40% by weight of a heat-resistant resin aqueous solution consisting of a 1:2% by weight mixture of 60% phenolic resin aqueous solution and 58% PTFE aqueous solution, and then dried at 60° C. for 1 hour , and preheated in a preheater at 80°C for 20 minutes using a knife folding machine, and then folded and cured in a post-heater at 330°C for 20 minutes to manufacture a pleated filter for high-temperature dust removal.

Embodiment 2

[0107] A pleated filter for high-temperature dust removal was produced in the same manner as in Example 1 except that a nonwoven fabric produced by hydroentanglement using polyimide was used.

Embodiment 3

[0109] A pleated filter for high-temperature dust removal was produced by the same method as in Example 1 except that a nonwoven fabric produced by hydroentanglement using PPS was used.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com