Feedback control method of granularity for crystal product in intermittent cooling and crystallization process

A technology of cooling crystallization and feedback control, applied in heat exchange cooling crystallization, crystallization adjustment/control, selection of crystallization auxiliary conditions, etc., can solve problems such as uneven particle size distribution of crystal products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] In this embodiment, erythritol is used as the research object.

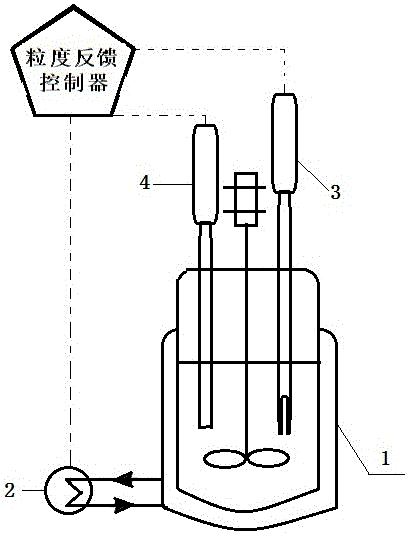

[0019] A feedback control method for the grain size of crystal products in the process of batch cooling and crystallization, which specifically includes a cooling crystallization system I, a crystal crushing system II, an online particle size detection system III, and a particle size feedback controller IV; the cooling crystallization system I is mainly composed of batch cooling The crystallizer (1) is composed of a temperature-controlled water bath (2) with an external circulation program, and the water bath (2) is connected to the jacket of the crystallizer (1) through an external circulation pipe to regulate the operating temperature in the crystallizer (1); The crystal crushing system II is a kind of submerged toothed rotor-stator wet mill (3); the online particle size detection system III can measure the total number N of crystal particles in the crystal slurry of the crystallizer (1) in real time , p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com