Flour product and preparation method for flour product

A production method and technology of noodle products, which are applied in the production of noodle products and the field of noodle products, can solve problems such as ultrasonic applications that have not yet been seen, and achieve the effect of apparent smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The preparation method of the flour product of the present embodiment comprises the following steps, wherein the flour product is noodles:

[0024] 1) Dough preparation: Add 150g of wheat flour to 65ml of salt water (dissolved with 4g of salt), and stir at a low speed until a flour flocculation without dry powder is formed;

[0025] 2) Ultrasonic curing: put the flour flocs obtained in step 1) into an ultrasonic machine, place them for 40 min at an ultrasonic power of 100 W and an ultrasonic frequency of 20 kHz, to obtain matured dough;

[0026] 3) Dough rolling: press the cooked dough obtained in step 2) into a dough sheet with a thickness of 3 mm, then put the dough sheet into a small noodle forming machine, and press it into noodles with a length of 200 mm, a width of 4 mm, and a thickness of 3 mm. Instantly.

[0027] The noodle product of this embodiment is noodles, which is obtained by the above-mentioned noodle product manufacturing method.

Embodiment 2

[0029] The preparation method of the flour product of the present embodiment comprises the following steps, wherein the flour product is noodles:

[0030] 1) Dough preparation: add 60ml of salt water (dissolved with 3g of salt) to 150g of wheat flour, and stir at a low speed until a flour flocculation without dry powder is formed;

[0031] 2) Ultrasonic curing: Put the dough obtained in step 1) into an ultrasonic machine, place it for 30 minutes at an ultrasonic power of 480W and an ultrasonic frequency of 40kHz, to obtain matured dough flocs;

[0032] 3) Dough rolling: Press the matured dough obtained in step 2) into a dough sheet with a thickness of 2mm, then put the dough sheet into a small noodle forming machine, and press it into noodles with a length of 200mm, a width of 4mm, and a thickness of 1.5mm , that is.

[0033] The noodle product of this embodiment is noodles, which is obtained by the above-mentioned noodle product manufacturing method.

Embodiment 3

[0035] The preparation method of the flour product of the present embodiment comprises the following steps, wherein the flour product is noodles:

[0036] 1) Dough preparation: Add 150g of wheat flour to 58ml of salt water (dissolved with 2.5g of salt), and stir at a low speed until a flour flocculation without dry powder is formed;

[0037] 2) Ultrasonic curing: Put the flour flocs obtained in step 1) into an ultrasonic machine, and place them for 20 minutes at an ultrasonic power of 700W and an ultrasonic frequency of 80kHz to obtain matured dough;

[0038] 3) Dough rolling: Press the matured dough obtained in step 2) into a dough sheet with a thickness of 1.5 mm, then put the dough sheet into a small noodle forming machine, and press it into a dough sheet with a length of 300 mm, a width of 7 mm, and a thickness of 1.5 mm. Noodles, ready to serve.

[0039] The noodle product of this embodiment is noodles, which is obtained by the above-mentioned noodle product manufacturin...

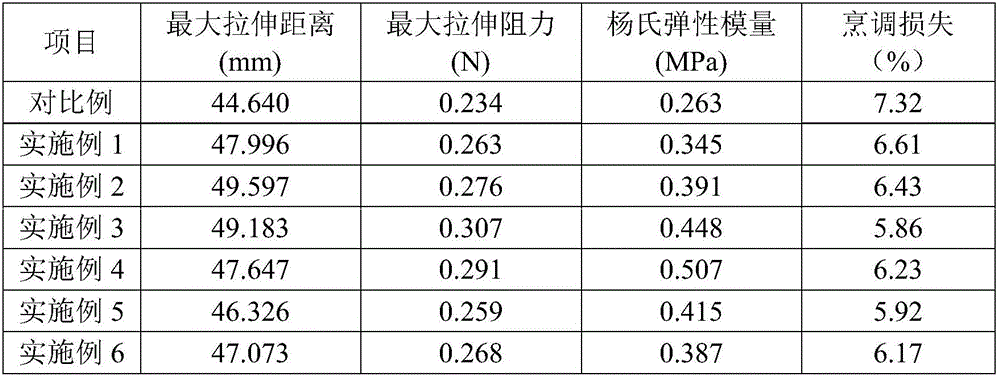

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Young's modulus of elasticity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com