Novel complex enzyme product special for ruminants and preparation method of novel complex enzyme product

A ruminant, compound enzyme technology, applied in the direction of animal feed, application, additional food elements, etc., can solve the problems of difficulty in applying ruminants, waste, affecting the production performance of ruminants, etc., to achieve rich varieties, stable product quality, and improved types. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

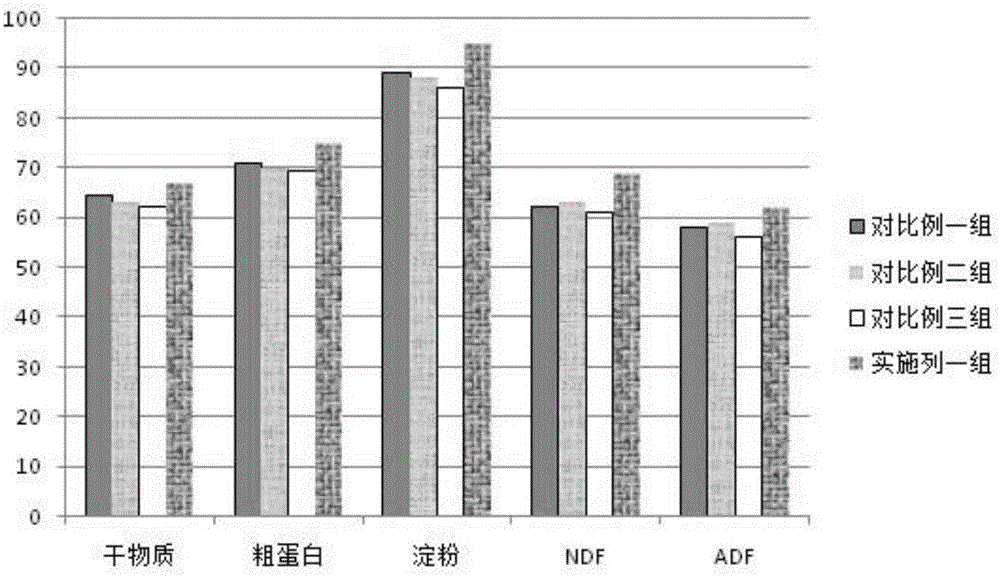

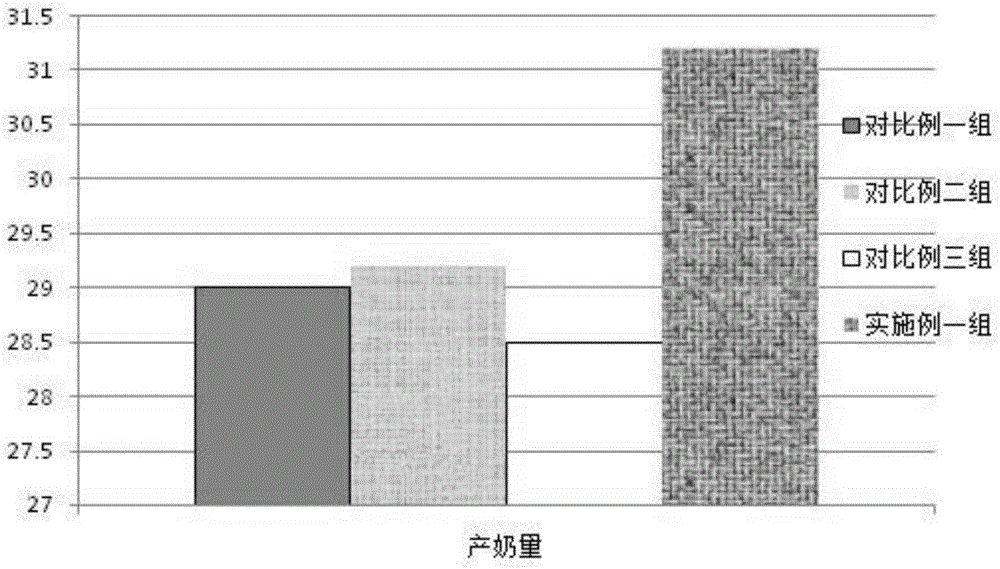

Embodiment 1

[0029] Embodiment one compound enzyme product

[0030] The compound enzyme product provided by the present invention includes the following components: xylanase 2000U / g, cellulase 3500U / g, β-glucanase 17500U / g, α-galactosidase 40U / g, α-starch Enzyme 37500U / g, acid protease 3750U / g, papain 3750U / g. α-amylase is coated with a rumen small intestine release coating material to make the first pellet, and the rumen small intestine release coating material is composed of ethyl cellulose, palmitic acid and fatty acid calcium in a weight ratio of 3:4:3; After the acid protease and papain are mixed, they are coated with the rumen abomasum release coating material to make the second pellet. The rumen abomasum release coating material is composed of fatty acid calcium, microcrystalline cellulose and polyacrylic acid resin IV. 5:3:2 weight ratio composition.

[0031] The preparation method of compound enzyme product comprises the steps:

Embodiment 2

[0034] Embodiment two compound enzyme product

[0035] The compound enzyme product provided by the present invention includes the following components: xylanase 2200U / g, cellulase 3200U / g, β-glucanase 17000U / g, α-galactosidase 30U / g, α-starch Enzyme 38000U / g, acid protease 4000U / g, papain 3500U / g. α-amylase is coated with a rumen small intestine release coating material to make the first pellet, and the rumen small intestine release coating material is composed of ethyl cellulose, palmitic acid and fatty acid calcium in a weight ratio of 3:4:3; After the acid protease and papain are mixed, they are coated with the rumen abomasum release coating material to make the second pellet. The rumen abomasum release coating material is composed of fatty acid calcium, microcrystalline cellulose and polyacrylic acid resin IV. 5:3:2 weight ratio composition.

[0036] The preparation method of compound enzyme product is the same as embodiment one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com