Normal-temperature drinking type yoghourt and preparation method thereof

A drinking-type, yogurt technology, applied in milk preparations, applications, dairy products, etc., can solve the problems of poor viscous taste, unsatisfactory production process, short shelf life of low-temperature drinking-type yogurt, etc., to reduce the scope of stabilizers , Guarantee the amount of milk used and improve the effect of viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

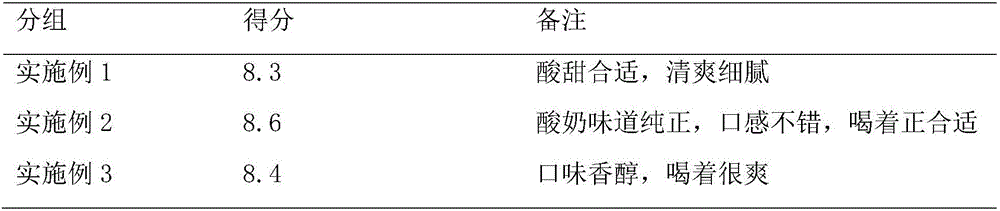

Embodiment 1

[0047] Raw materials are taken according to the following mass percentages: 81% of fresh milk, 8.5% of white sugar, 2% of whey protein powder, 0.4% of pectin, 0.15% of agar, 0.01% of gellan gum, 0.02% of food essence, and water supplemented to 100% %. Prepare yogurt first, take part of the milk and heat it up to about 50°C, add whey protein powder, agar, gellan gum, and white sugar, dissolve with high shear for 15-20min, preheat at 65-70°C, homogenize at 20-22MPa, and 95°C , sterilized for 300s; cooled to 42°C, added strains for fermentation. Two hours before the end of yogurt fermentation, raise the temperature to 80°C with RO water, add pectin, circulate and dissolve for 15 minutes, and cool to below 40°C for later use. After the yogurt fermentation is over, add the pectin solution into the fermented yogurt, homogenize it under air pressure, heat-treat it at 80°C for 15s plate pasteurization, cool it down to below 25°C, and transfer it to an aseptic tank. It is filled in a...

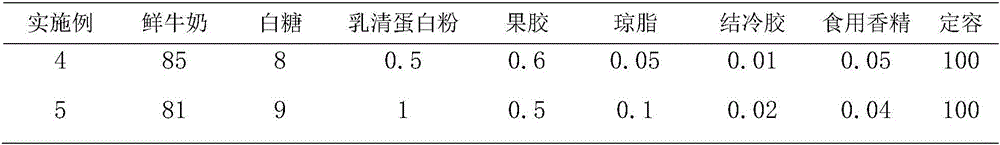

Embodiment 2

[0049] A normal-temperature drinkable yogurt, which is made of the following raw materials in mass percentage: 83% fresh milk, 9% white sugar, 1.5% whey protein powder, 0.5% pectin, 0.1% agar, 0.03% gellan gum, food Use 0.03% essence and add water to 100%. The preparation steps are the same as in Example 1.

Embodiment 3

[0051] A normal-temperature drinkable yogurt, which is made of the following raw materials in mass percentage: 83% fresh milk, 9.5% white sugar, 2% whey protein powder, 0.5% pectin, 0.05% agar, 0.02% gellan gum, food Use 0.04% essence and water to make up to 100%, and the preparation steps are the same as in Example 1.

[0052] Heat part of the milk to about 50°C, add whey protein powder, agar, gellan gum, white sugar and other auxiliary materials, high-shear and dissolve for 15-20min, preheat at 65-70°C, homogenize at 20-22MPa, sterilize at 95°C for 300s ; Cool to 42 ° C, add strains for fermentation. Two hours before the end of yogurt fermentation, heat up to 80°C with RO water, add pectin, circulate and dissolve for 15 minutes, and cool for later use. Add the pectin solution into the fermented yogurt, homogenize under air pressure, 80°C, 15s plate pasteurization heat treatment, cool to below 25°C and transfer to the aseptic tank. After being filled in aseptic packaging an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com