High-frequency and high-speed electronic circuit board based on high thickness-radius ratio deep hole electroplating technology

A deep-hole electroplating, high-speed electronic technology, applied in flexible printed circuit boards, circuit devices, printed circuits, etc., can solve the problems of increased interlayer, too dense component row of high-frequency circuits, radiation interference, etc., to achieve proper design , reducing the volume, good heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

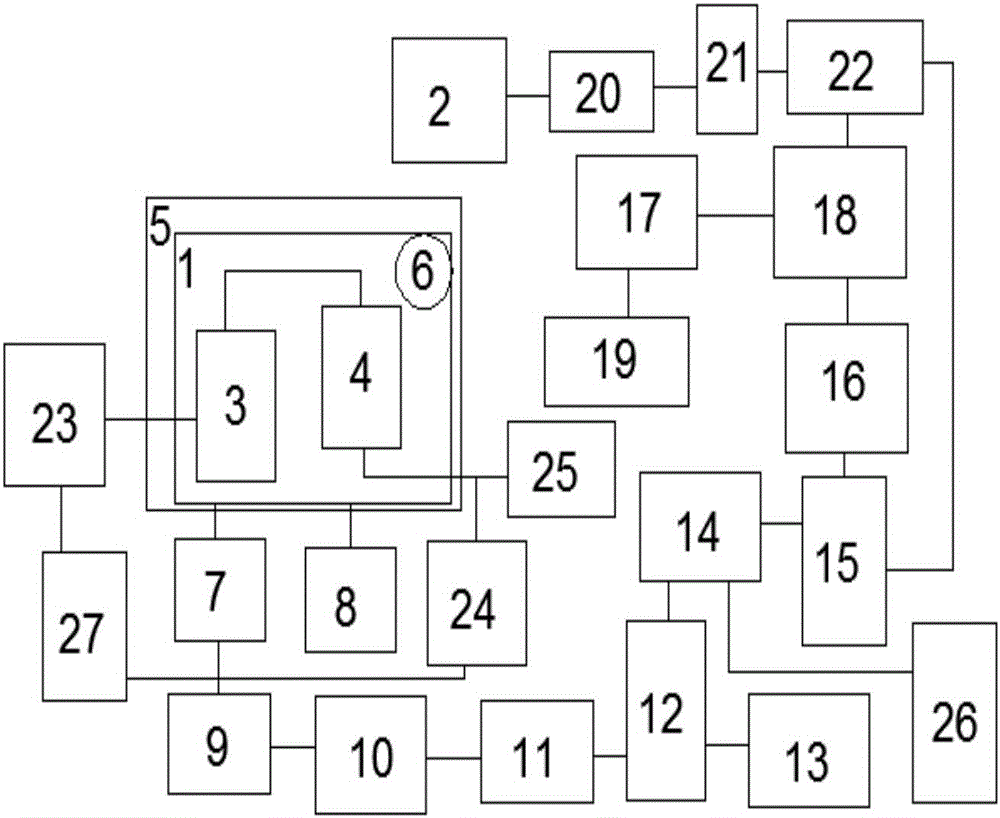

[0014] see figure 1 and figure 2 , the present invention provides a technical solution: a high-frequency and high-speed electronic circuit board based on high-thickness-diameter ratio deep-hole electroplating technology, including a main control board 1 and a signal transmission module 2, and the main control board 1 includes a receiving chip 3 and a driver Chip 4, the communication port of the receiving chip 3 is connected with the driver chip 4 through the control line, and the input terminal of the receiving chip 3 is also connected with the clock control bus 23, and the input terminal of the driver chip 4 is connected with the gate signal respectively. Line 24 is connected with data signal line 25, and strobe signal line 24 is connected with clock control bus 23 through delay circuit 27, and described main control board 1 adopts double-sided flexible circuit board, and outside main control board 1 The surface is also provided with polycool resin material 5, four holes 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com