Power cable sealed transmission mechanism for low-temperature submersed pump

A power cable and transmission mechanism technology, applied in the direction of machines/engines, air-filled/oil-filled cable accessories, pumps, etc., can solve problems such as technical support can not keep up, manufacturing and testing difficulties, high product prices, etc., to achieve avoidance performance The effect of lowering, simple structure, and reducing maintenance and replacement costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

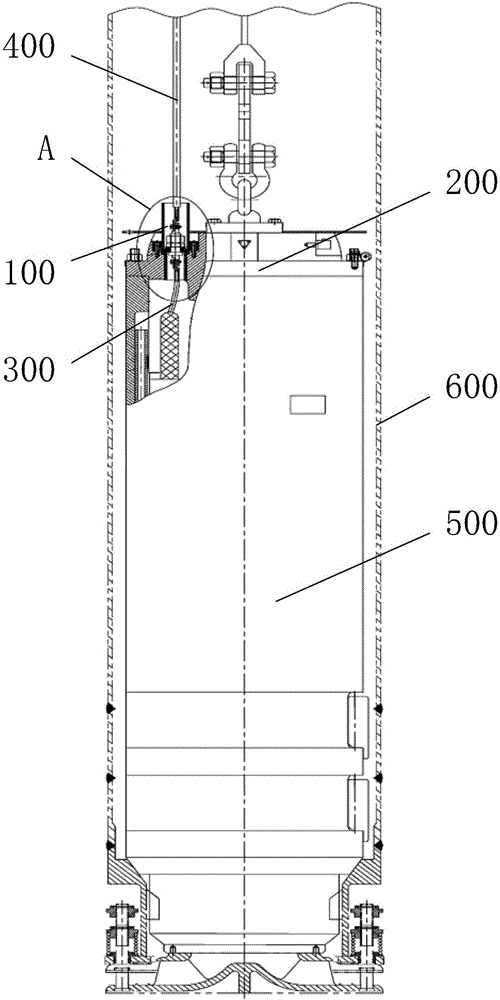

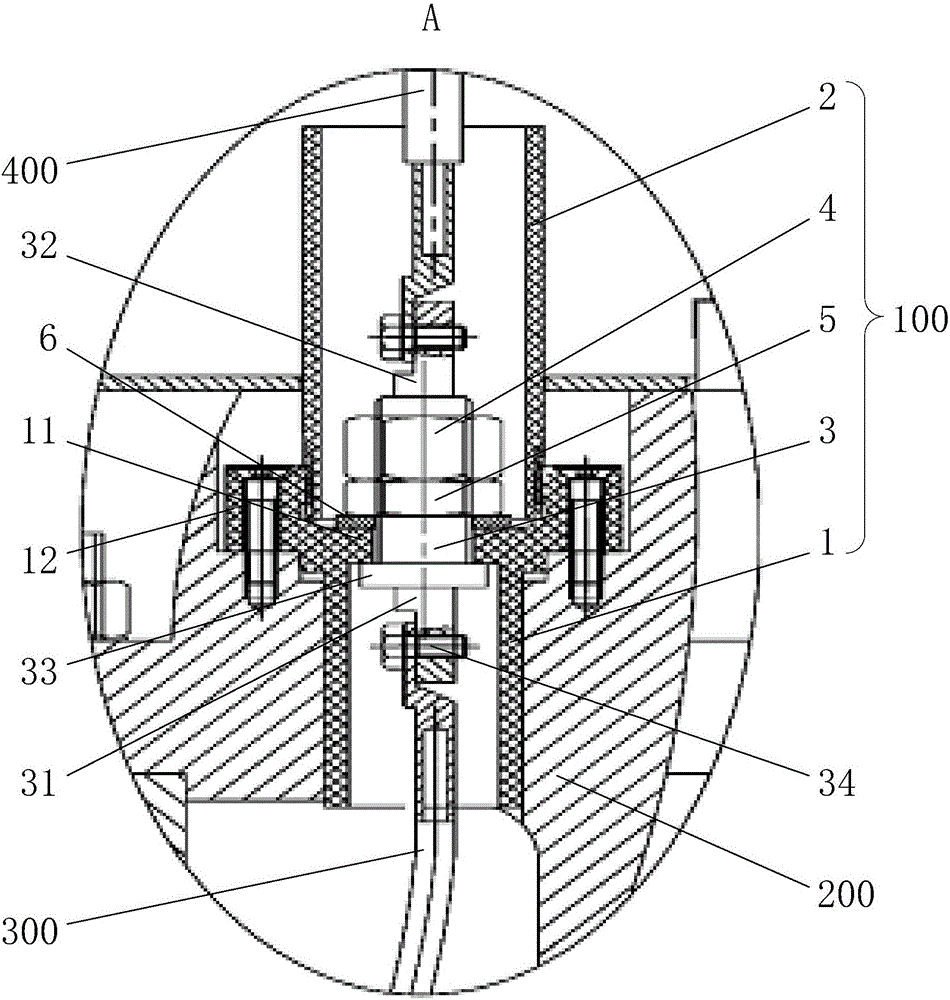

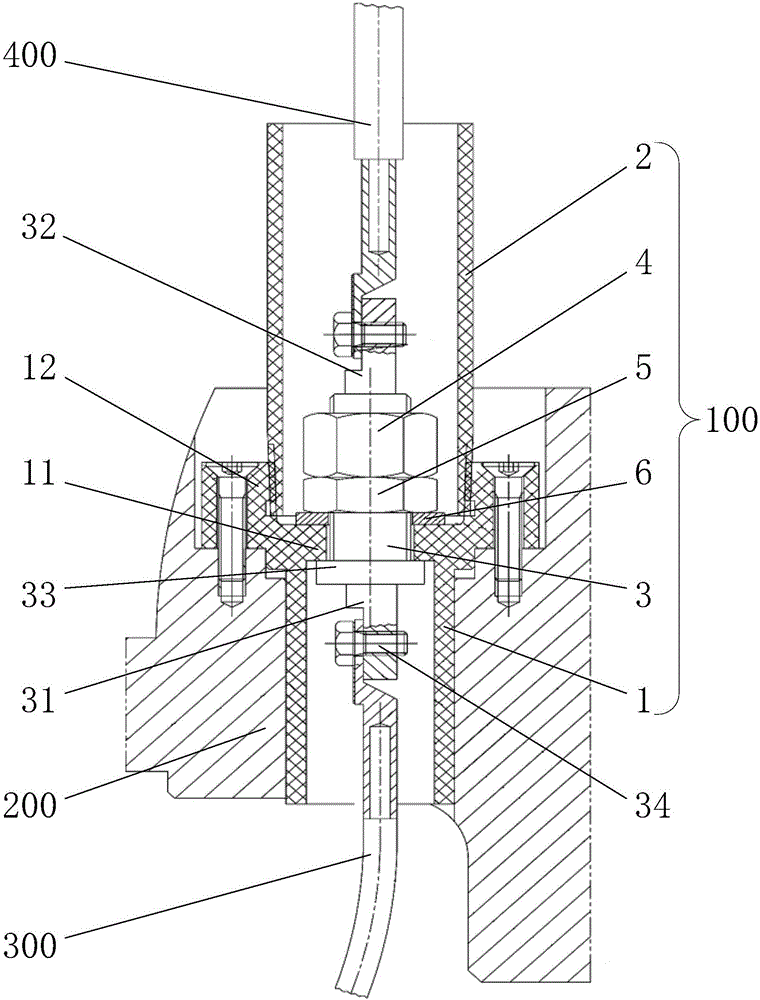

[0016] Such as figure 1 , figure 2 and image 3 As shown, the present invention provides a power cable sealing transmission mechanism 100 for a cryogenic submersible pump, which includes a first insulating sleeve 1, a second insulating sleeve 2 and a copper conductor 3; wherein the first insulating sleeve 1 is in the form of A hollow cylindrical shape with one end open and the other end sealed, the power cable sealing transmission structure 100 is fixedly and airtightly connected to the motor end cover 200 of the cryogenic submersible pump 500 through the first insulating sleeve 1 , and the opening of the first insulating sleeve 1 One end of the motor end cover 200 leads to the inside of the cryogenic submersible pump 500; the second insulating sleeve 2 is in the shape of a hollow cylinder with two ends open, one end is fixed and sealed with the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com