A high-efficiency and stable perovskite battery containing impermeable carbon film and its preparation method

A perovskite battery and carbon thin film technology, which is applied in circuits, electrical components, photovoltaic power generation, etc., can solve problems such as entry, poor repeatability, and affecting battery stability, and achieve a good combination effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] 1. On the ITO substrate, dense TiO is sequentially prepared 2 Electron transport layer, FAPbI 3 perovskite thin film.

[0044] 2. On the perovskite film, a uniform and dense graphite film with a thickness of 100 nm is prepared on the perovskite film by magnetron sputtering. The carbon film color is a very light gray.

[0045] 3. On the dense graphite film, scrape a layer of commercial carbon paste with a thickness of about 15 μm by the scraper method.

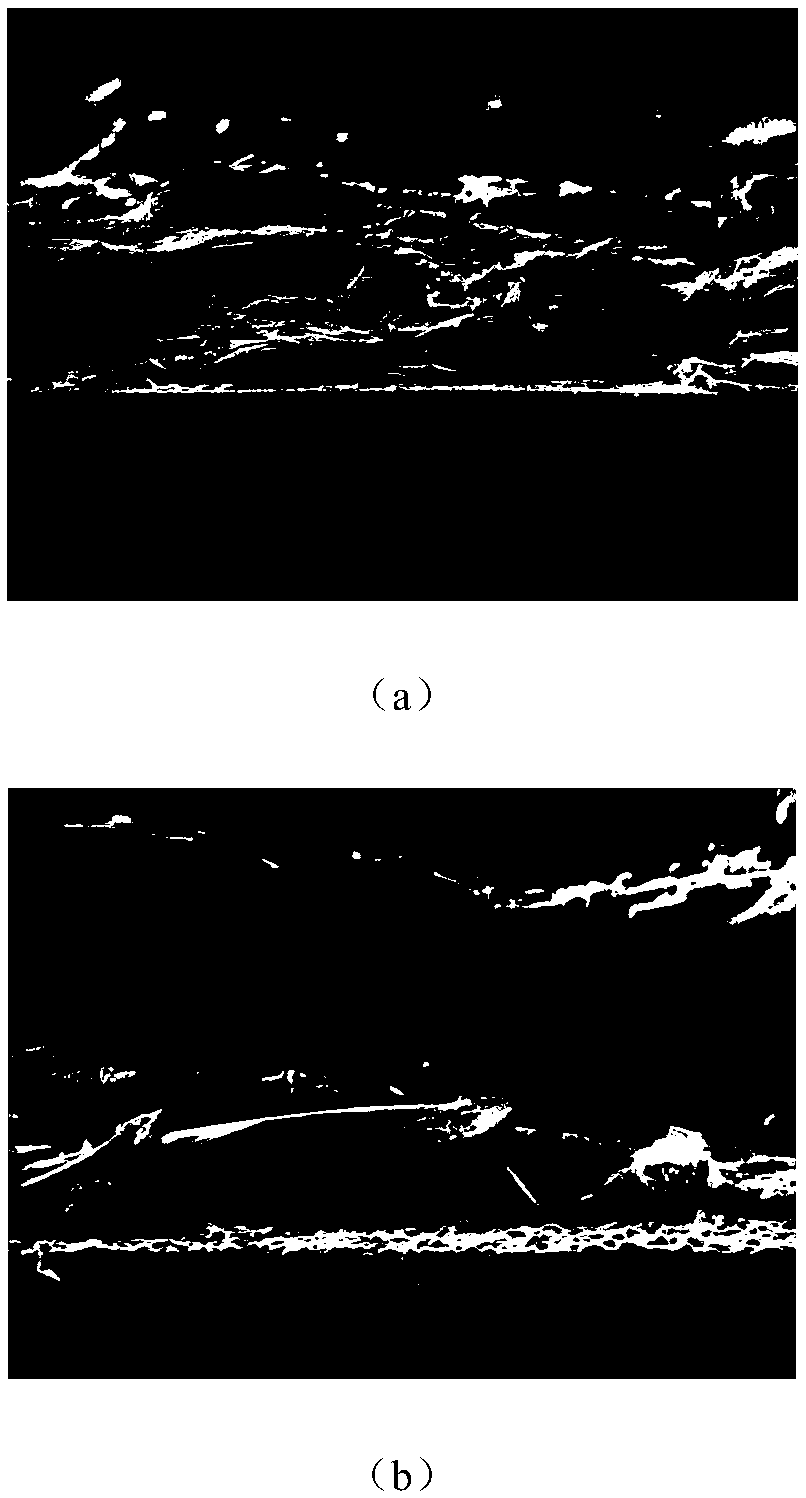

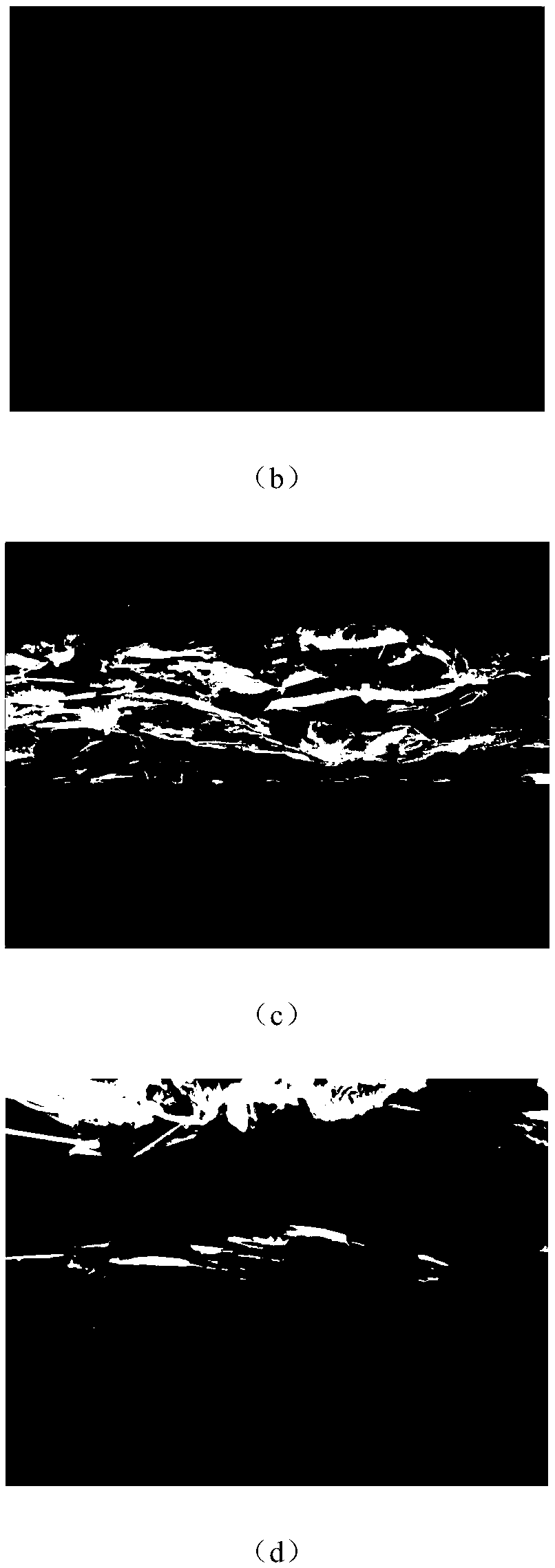

[0046] 4. Place the prepared battery on a hot plate and heat for 15 minutes to evaporate the solvent. Test and record the surface morphology of the carbon film as figure 2 (a), figure 2 (b), the cross-sectional morphology of the battery is as follows figure 2 (c), figure 2 As shown in (d), it can be seen that there is a uniform and dense carbon film between the perovskite and the carbon electrode, and the morphology of the perovskite is kept intact without corrosion.

Embodiment 2

[0048] 1. On the FTO substrate, dense TiO is sequentially prepared 2 Electron transport layer, FAPbI 3 Perovskite thin films and hole transport layers.

[0049] 2. On the hole transport layer, a uniform and dense nano-carbon film with a thickness of 5 nm is prepared on the perovskite film by magnetron sputtering.

[0050] 3. On the dense nano-carbon film, use a doctor blade method to scrape a layer of commercial carbon paste with a thickness of about 15 μm.

[0051] 4. Place the prepared battery on a hot plate and heat it for 15 minutes to volatilize the solvent, and obtain a highly efficient and stable perovskite battery containing an impermeable carbon film.

Embodiment 3

[0053] 1. On the ITO substrate, dense TiO is sequentially prepared 2 Electron transport layer, FAPbI 3 perovskite thin film.

[0054] 2. On the perovskite film, a uniform and dense nano-carbon film with a thickness of 5 μm and a uniform and dense graphene film with a thickness of 5 μm were prepared on the perovskite film by magnetron sputtering.

[0055] 3. On the dense nano-carbon film, use a doctor blade method to scrape a layer of commercial carbon paste with a thickness of about 15 μm.

[0056] 4. Place the prepared battery on a hot plate and heat it for 15 minutes to volatilize the solvent, and obtain a highly efficient and stable perovskite battery containing an impermeable carbon film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com