Relative humidity sensor based on PCF air chamber and tilted fiber bragg grating

A tilted fiber grating, relative humidity technology, applied in instruments, scientific instruments, phase influence characteristic measurement, etc., can solve problems such as the inability to meet the actual needs of humidity sensing, and achieve improved sensitivity and thermal stability, compact structure, and enhanced coupling. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

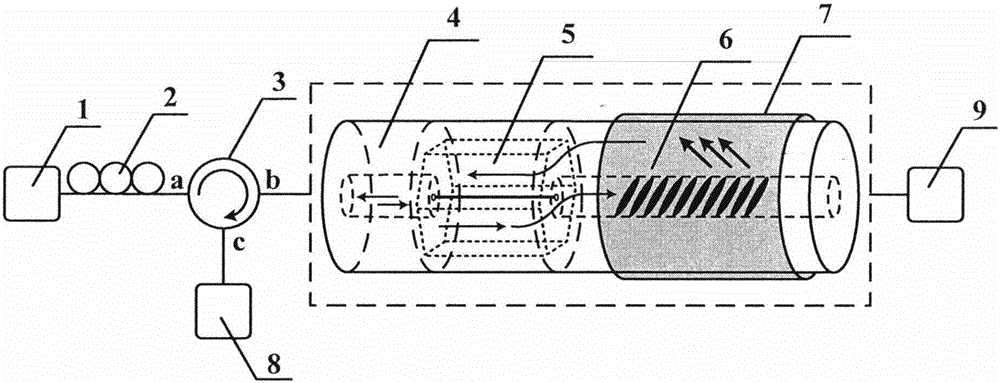

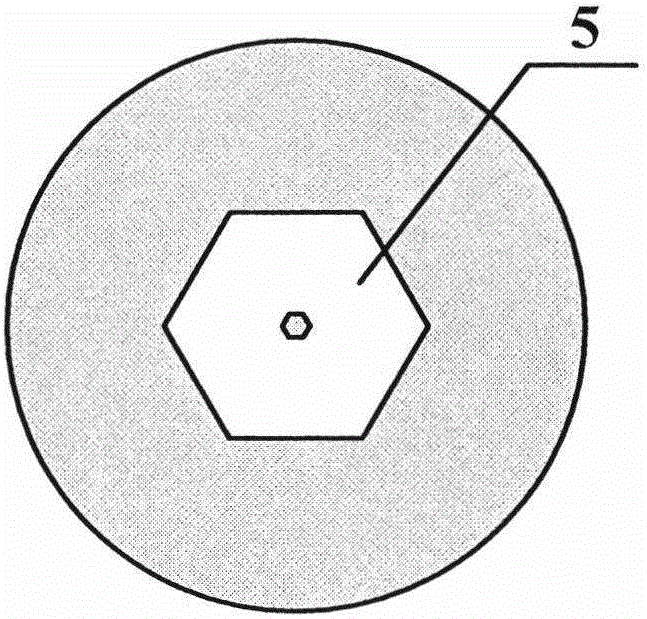

[0023] See attached figure 1 , a relative humidity sensor based on a PCF air cavity and a tilted fiber grating, characterized in that: a broadband light source (1), a polarization controller (2), an optical fiber circulator (3), a single-mode optical fiber (4), a PCF air A cavity (5), a tilted fiber grating (6), a graphene oxide film (7), a first spectrometer (8), and a second spectrometer (9); the broadband light source (1) circulates with the optical fiber through a polarization controller (2) The a port of the optical fiber circulator (3) is connected to the a port, and the b port of the optical fiber circulator (3) is connected to the left end of the single-mode optical fiber (4); the single-mode optical fiber (4), the PCF air cavity (5), the inclined fiber grating (6) and The graphene oxide film (7) constitutes a moisture-sensit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com