Ignition device with flame stabilization function for liquid fuel ramjet engine

A ramjet and flame stabilization technology, applied in the field of ramjet, can solve the problems of increasing the complexity of the structure, low temperature of the oil and gas mixture, difficult gas ignition, etc., and achieve the effect of increasing the point or reliability, simplifying the assembly difficulty, and improving the reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

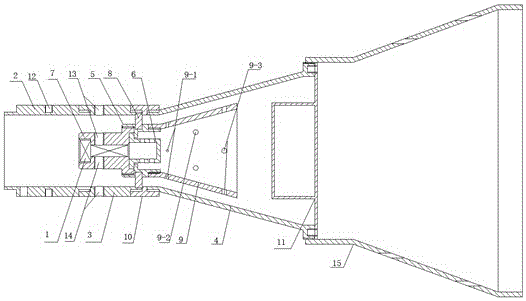

[0022] combine figure 1 , an ignition device for a liquid ramjet with a flame stabilization function, comprising an igniter, an oil supply passage 13, an air supply passage 14, a front casing 2, a middle casing 3, a connecting ring 10, a rear casing 4, an expansion Pipe 9, flame stabilizer 11, main combustion chamber flame stabilizer 15 and four fastening plugs 8, front housing 2 and middle housing 3 are fixedly connected by threads, middle housing 3 and rear housing 4 are connected by connecting ring 10 Fixed connection, the igniter is located at the junction of the middle housing 3 and the rear housing 4, the segmented design of the housing facilitates the installation of the igniter, four fastening plugs 8 are symmetrically distributed on the inner wall of the connecting ring 10, and the fastening plugs 8. One end is clamped between the connecting ring 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com