Ceramic tile back coating glue and preparation method thereof, and tile adhering method

A back-coating and ceramic tile technology, applied in adhesives, adhesive additives, construction, etc., can solve the problems of overall slurry performance cost constraints, occupying construction time, large amount of tile adhesive, etc., to improve construction efficiency and construction performance, Reduced construction cost and low temperature cracking resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

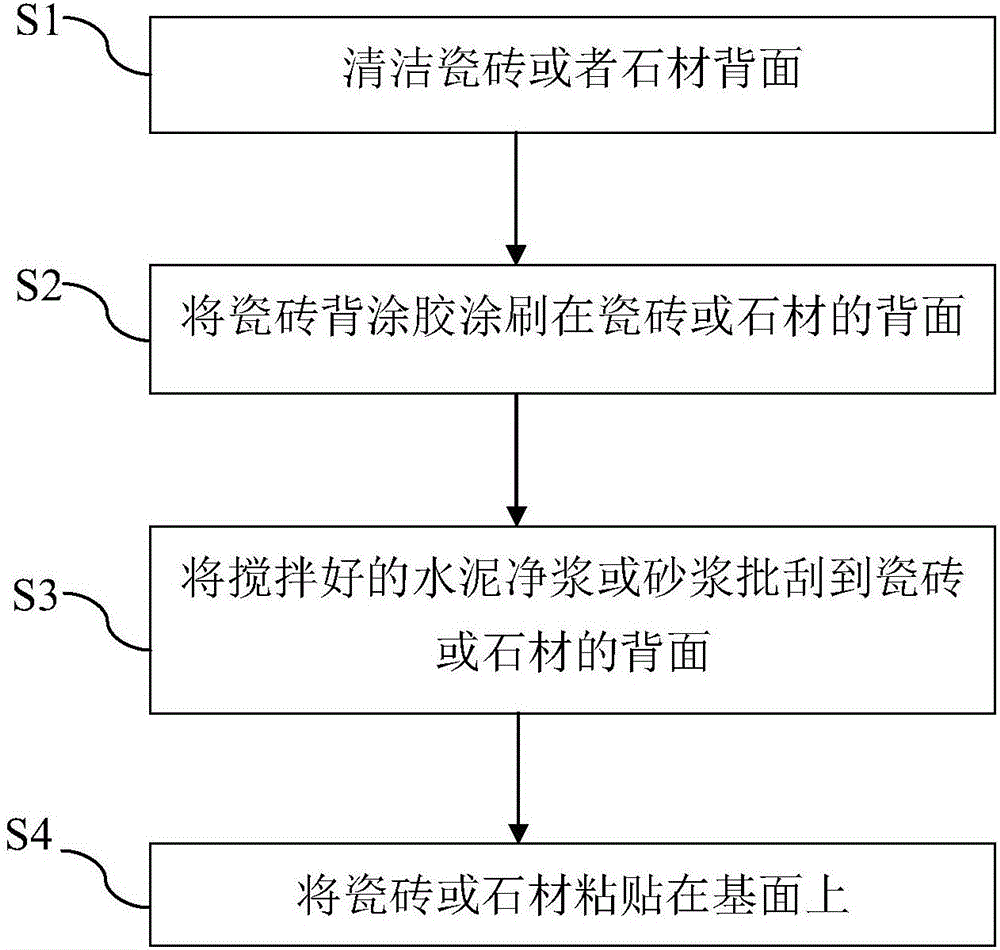

Method used

Image

Examples

experiment example 1

[0035] Add 350 kg of styrene-butadiene emulsion and 600 kg of acrylic acid emulsion into a 1500-liter tank mixer in sequence, and keep stirring at a stirring speed of 20 rpm for 3 minutes until the two are fully mixed; then pour 10 kg of propylene glycol into the reactor. Thereafter, 75kg of nano-calcium carbonate was fed from the top of the stirrer, and the feeding was completed at a constant speed within 15 minutes, while continuing to stir, and 15kg of calcium formate was dropped at a constant speed within 10 minutes. Afterwards, put the remaining auxiliary materials chelating coupling agent 7kg, wetting and dispersing agent 4kg, shrinkage reducing agent 3kg, bactericide 1kg, defoamer 0.1kg, yellow pigment 0.3kg in sequence, and throw them all within 15 minutes. Then mix well.

[0036] The total mass of the ceramic tile back glue that makes is 1065.4kg, wherein, the massfraction of styrene-butadiene emulsion is 32.85% (350 / 1065.4), the massfraction of acrylic acid emulsion ...

experiment example 2

[0042] Add 400kg of styrene-butadiene emulsion and 498kg of acrylic acid emulsion into a 1500-liter tank mixer in turn, and keep stirring at a stirring speed of 20rpm for 3 minutes until the two are fully mixed; then pour 16kg of propylene glycol into the reactor. Thereafter, 50 kg of nano-calcium carbonate was fed from the top of the stirrer, and the feeding was completed at a uniform speed within 15 minutes, while continuing to stir, and 20 kg of calcium formate was dropped at a uniform speed within 10 minutes. Afterwards, add 6kg of chelating coupling agent, 4.5kg of wetting and dispersing agent, 3kg of shrinkage reducing agent, 2kg of fungicide, 0.5kg of defoamer, and 0.2kg of yellow pigment in sequence, and finish all the injection within 15 minutes. , and then mix thoroughly.

[0043] The total mass of the ceramic tile back glue that makes is 1000.2kg, wherein, the massfraction of styrene-butadiene emulsion is 39.99% (400 / 1000.2), the massfraction of acrylic acid emulsio...

experiment example 3

[0049] Add 490 kg of styrene-butadiene emulsion and 408 kg of acrylic acid emulsion into a 1500-liter tank mixer in sequence, and keep stirring at a stirring speed of 20 rpm for 3 minutes until the two are fully mixed; then pour 16 kg of propylene glycol into the reactor. Thereafter, 50 kg of nano-calcium carbonate was fed from the top of the stirrer, and the feeding was completed at a uniform speed within 15 minutes, while continuing to stir, and 20 kg of calcium formate was dropped at a uniform speed within 10 minutes. Afterwards, add 6kg of chelating coupling agent, 4.5kg of wetting and dispersing agent, 3kg of shrinkage reducing agent, 2kg of fungicide, 0.5kg of defoamer, and 0.2kg of yellow pigment in sequence, and finish all the injection within 15 minutes. , and then mix thoroughly.

[0050] The total mass of the ceramic tile back glue that makes is 1000.2kg, wherein, the massfraction of styrene-butadiene emulsion is 48.99% (490 / 1000.2), the massfraction of acrylic acid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com