Anti-flaming polylactic acid plastic for automotive trim

A polylactic acid and plastic technology, applied in the field of plastic processing, to achieve the effect of improving flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

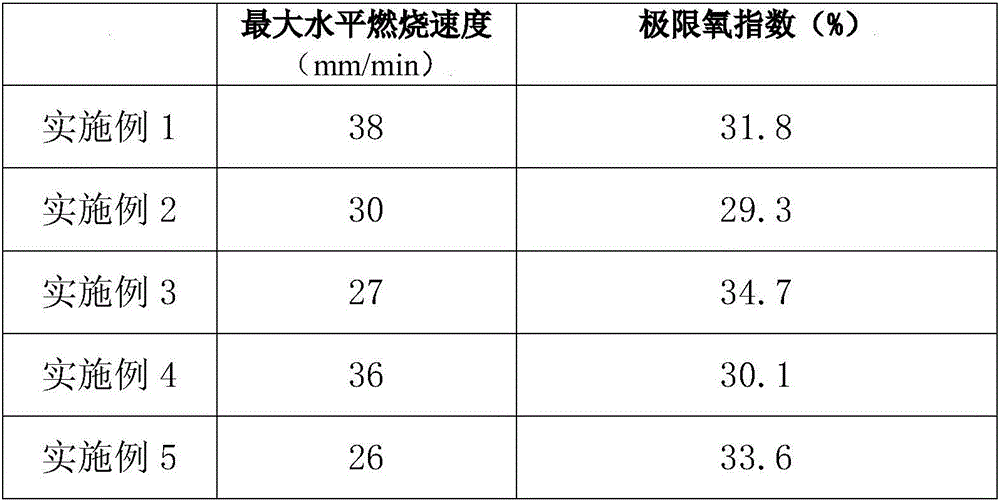

Examples

Embodiment 1

[0028] A flame-retardant polylactic acid plastic for automotive interior, which is prepared by the following method:

[0029] (1) Degumming treatment of asparagus fiber:

[0030] Chemical degumming method for degumming treatment;

[0031] (2) Microbial fermentation modified asparagus fiber:

[0032] Bacillus licheniformis, Bacillus subtilis, and Acetobacter xylinum are formulated into a composite bacterial agent according to the quantitative ratio of 1:0.5:0.8;

[0033] Wash the degummed asparagus, spray the fungus evenly, and ferment at 38°C for 38 hours. After the fermentation is over, wash it with warm water, shake it loose, and dry it;

[0034] (3) Blending of raw materials:

[0035] Set the temperature at 160°C, preheat for 1 hour, and configure the dried raw materials according to the following weight fractions: 10 parts of modified asparagus fiber, 90 parts of polylactic acid, 2 parts of chitosan powder; 0.5 part of nano-montmorillonite powder, 0.8 parts of calcium ...

Embodiment 2

[0041] A flame-retardant polylactic acid plastic for automotive interior, which is prepared by the following method:

[0042] (1) Degumming treatment of asparagus fiber:

[0043] Chemical degumming method for degumming treatment;

[0044] (2) Microbial fermentation modified asparagus fiber:

[0045] Bacillus licheniformis, Bacillus subtilis, and Acetobacter xylinum are formulated into a composite bacterial agent according to the quantitative ratio of 1:0.9:0.8;

[0046] Wash the degummed asparagus, spray the fungus evenly, and ferment at 38°C for 20 hours. After the fermentation, wash it with warm water, shake it loose, and dry it;

[0047] (3) Blending of raw materials:

[0048] Set the temperature at 160°C, preheat for 1 hr, and configure the dried raw materials according to the following weight fractions: 15 parts of modified asparagus fiber, 80 parts of polylactic acid, 2 parts of chitosan powder; 0.5 part of nano-montmorillonite powder, 0.8 parts of calcium carbonate;...

Embodiment 3

[0054] A flame-retardant polylactic acid plastic for automotive interior, which is prepared by the following method:

[0055] (1) Degumming treatment of asparagus fiber:

[0056] Chemical degumming method for degumming treatment;

[0057] (2) Microbial fermentation modified asparagus fiber:

[0058]Bacillus licheniformis, Bacillus subtilis, and Acetobacter xylini are formulated into a composite bacterial agent according to the quantitative ratio of 1:0.6:0.8;

[0059] Wash the degummed asparagus, spray the bacteria evenly, and ferment at 38°C for 30 hours. After the fermentation, wash with warm water, shake loose, and dry;

[0060] (3) Blending of raw materials:

[0061] Set the temperature at 160°C, preheat for 1 hr, and configure the dried raw materials according to the following weight fractions: 11 parts of modified asparagus fiber, 89 parts of polylactic acid, 2 parts of chitosan powder; 0.5 part of nano-montmorillonite powder, 0.8 parts of calcium carbonate;

[0062...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com