Polyacetal resin molding

A technology of polyacetal resin and molded body, applied in the field of polyacetal resin molded body, can solve the problems of sticking, difficult to produce products, sticking of molded body, etc., and achieve excellent blocking resistance, stable sliding property, and low odor. excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1、2

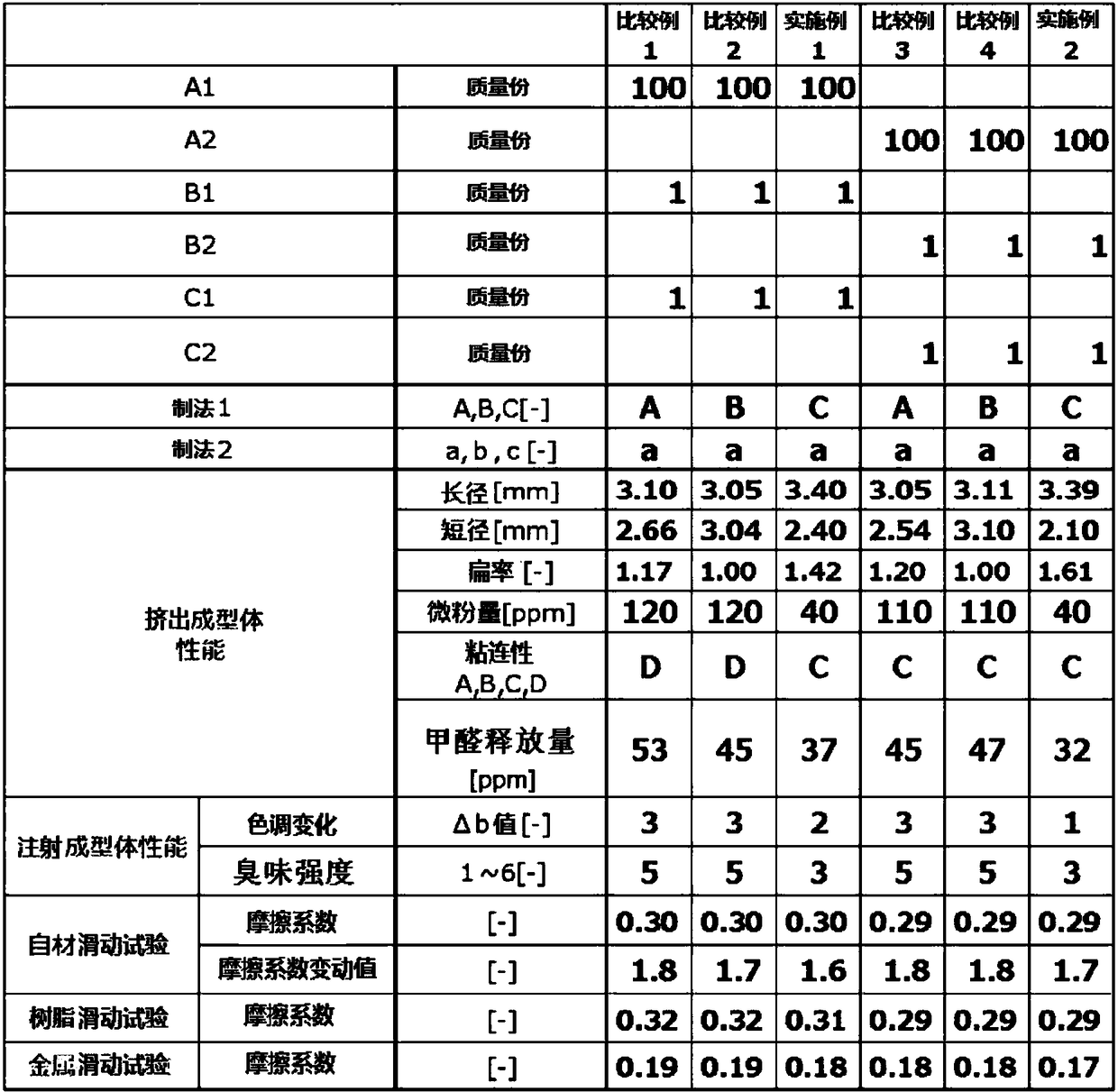

[0208] [Example 1, 2, Comparative Examples 1-4]

[0209] Each component was blended in the ratio shown in Table 1, and melt-kneaded according to the above-mentioned production method to obtain a resin molded body. Using the obtained molded body, various physical properties were evaluated. By changing the production method based on the results, a molded article having the desired shape in this embodiment can be obtained. It can be seen that in Examples 1 and 2 where such a molded article was obtained, the amount of fine powder was reduced, the blocking property was improved, and formaldehyde was released. amount decreased. It was also found that the color change and the intensity of the odor were improved after injection molding.

[0210] [Table 1]

[0211]

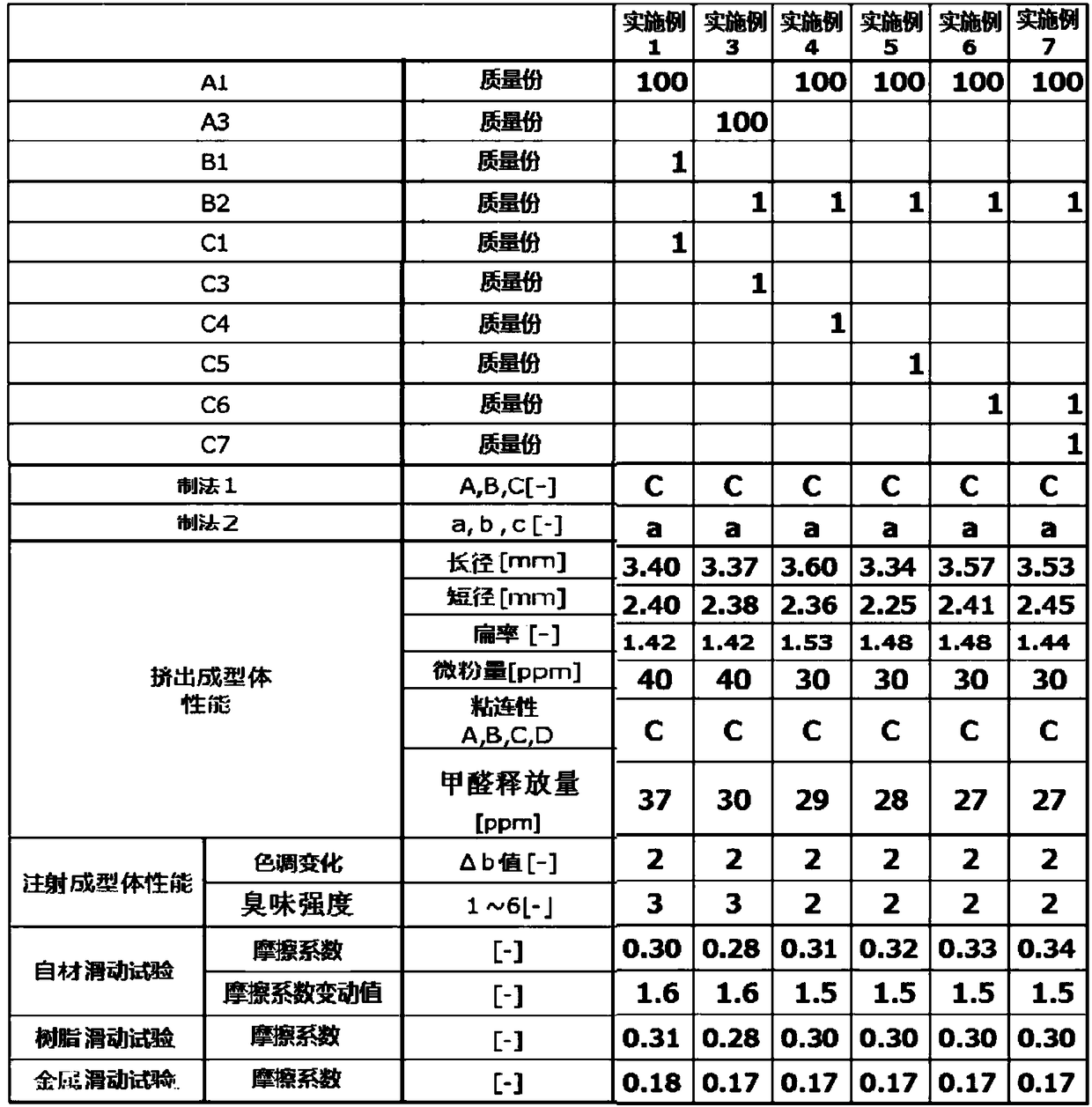

Embodiment 1、3~7

[0213] Each component was blended in the ratio shown in Table 2, and melt-kneaded according to the above-mentioned production method to obtain a resin molded body. Using the obtained molded body, various physical properties were evaluated. It can be seen that by changing the composition, the amount of fine powder, adhesion, and formaldehyde emission are kept at a certain level, and the performance and friction coefficient of the molded sheet change in this state, and the friction coefficient variation value is improved.

[0214] [Table 2]

[0215]

Embodiment 1、8~11

[0217] Each component was blended in the ratio shown in Table 3, and melt-kneaded according to the above-mentioned production method to obtain a resin molded body. Using the obtained molded body, various physical properties were evaluated. It can be seen that the sliding performance is further improved by using the component (C) in combination, and the variation value of the friction coefficient is also improved. In addition, it has been found that not only self-material sliding tests but also resin sliding tests and metal sliding tests can be improved by using them in combination.

[0218] [table 3]

[0219]

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com