Saline-alkali soil improving agent, and preparation method thereof

An improvement agent and saline-alkali land technology, which is applied in the field of saline-alkali land improvement agent and its preparation, can solve the problems of serious soil compaction, failure to improve compaction, and increase in soil bulk density, so as to improve the soil environment, improve stress resistance, and improve soil structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

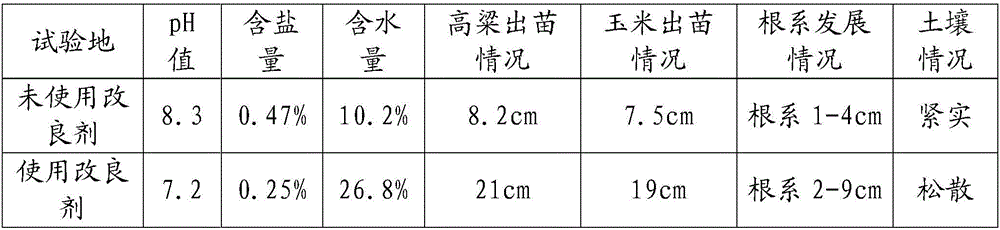

Image

Examples

Embodiment 1

[0036] The saline-alkali soil improver of the present invention comprises the following raw materials in proportion by weight: 5 parts of humic acid, 4 parts of furfural slag, 5 parts of phosphate rock powder, 2 parts of vermiculite, 1 part of medical stone, 2 parts of wood vinegar, fermented plant fiber 30 parts, 40 parts of fermented animal manure, 0.5 parts of microbial agent, 3 parts of sodium alginate and 2 parts of polyacrylamide.

[0037] The humic acid used is a mixture of black humic acid, fulvic acid and brown humic acid in a ratio of 1:1:1 by weight.

[0038] The furfural slag used is the waste residue produced after the mixture of corncobs, corn stalks, rice husks, cottonseed hulls and agricultural by-product processing leftovers is hydrolyzed by Bacillus subtilis to produce furfural under the action of catalyst sulfuric acid.

[0039] The fermented plant fiber used is a mixture of sawdust, rice husk, wheat bran, crop stalks, fallen leaves and moss, which is obtain...

Embodiment 2

[0057] The saline-alkali soil improver of the present invention comprises raw materials in the following proportions by weight: 10 parts of humic acid, 6 parts of furfural slag, 8 parts of phosphate rock powder, 5 parts of vermiculite, 3 parts of medical stone, 4 parts of wood vinegar, fermented plant fiber 45 parts, 70 parts of fermented animal manure, 2 parts of microbial agent, 6 parts of sodium alginate and 5 parts of polyacrylamide.

[0058] Among them, humic acid is fulvic acid.

[0059] The furfural slag used is the waste residue produced after the mixture of corncobs, corn stalks, rice husks, cottonseed hulls and agricultural by-product processing leftovers is hydrolyzed by Bacillus subtilis to produce furfural under the action of catalyst sulfuric acid.

[0060] The fermented plant fiber used is a mixture of sawdust, rice husk, wheat bran, crop stalks, tree leaves and moss, which is obtained by fermenting the plant fiber fermentation mixture at a weight ratio of 1:5:3...

Embodiment 3

[0070] The saline-alkali soil improver of the present invention includes the following raw materials in proportion by weight: 8 parts of humic acid, 5 parts of furfural slag, 2.5 parts of phosphate rock powder, 3 parts of vermiculite, 2 parts of medical stone, 3 parts of wood vinegar, fermented plant fiber 38 parts, 55 parts of fermented animal manure, 1.5 parts of microbial agent, 4 parts of sodium alginate and 3 parts of polyacrylamide.

[0071] The humic acid used is a mixture of black humic acid, fulvic acid and brown humic acid in a ratio of 1:3:1 by weight.

[0072] The furfural slag used is the waste residue produced after the mixture of corncobs, corn stalks, rice husks, cottonseed hulls and agricultural by-product processing leftovers is hydrolyzed by Bacillus subtilis to produce furfural under the action of catalyst sulfuric acid.

[0073] The fermented plant fiber used is a mixture of sawdust, rice husk, wheat bran, crop stalks, tree leaves and moss, which is obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com