A two-way synchronous rotating clamping device for steel pipe cutting

A two-way synchronization, clamping device technology, applied in positioning devices, auxiliary devices, welding/cutting auxiliary equipment, etc., can solve the problem that the steel pipe cannot be clamped and rotated, so as to reduce the force, the cutting process is efficient, and the guarantee The effect of clamping quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

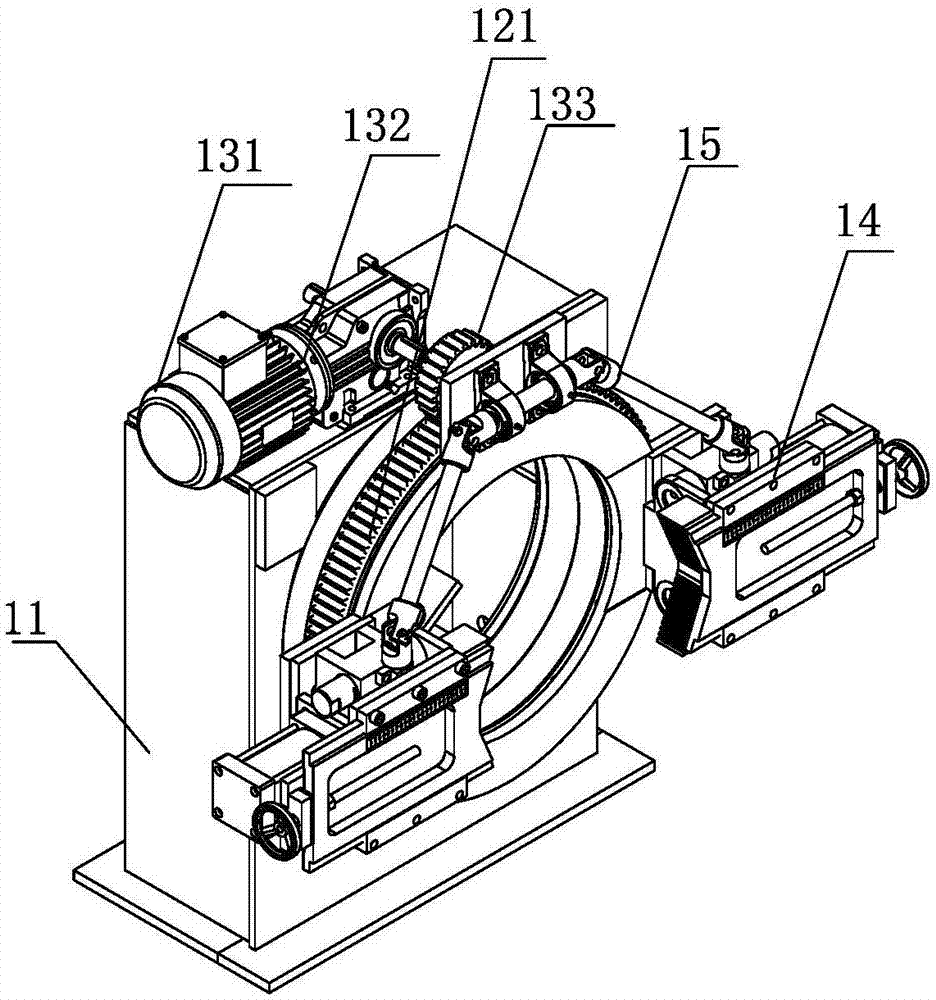

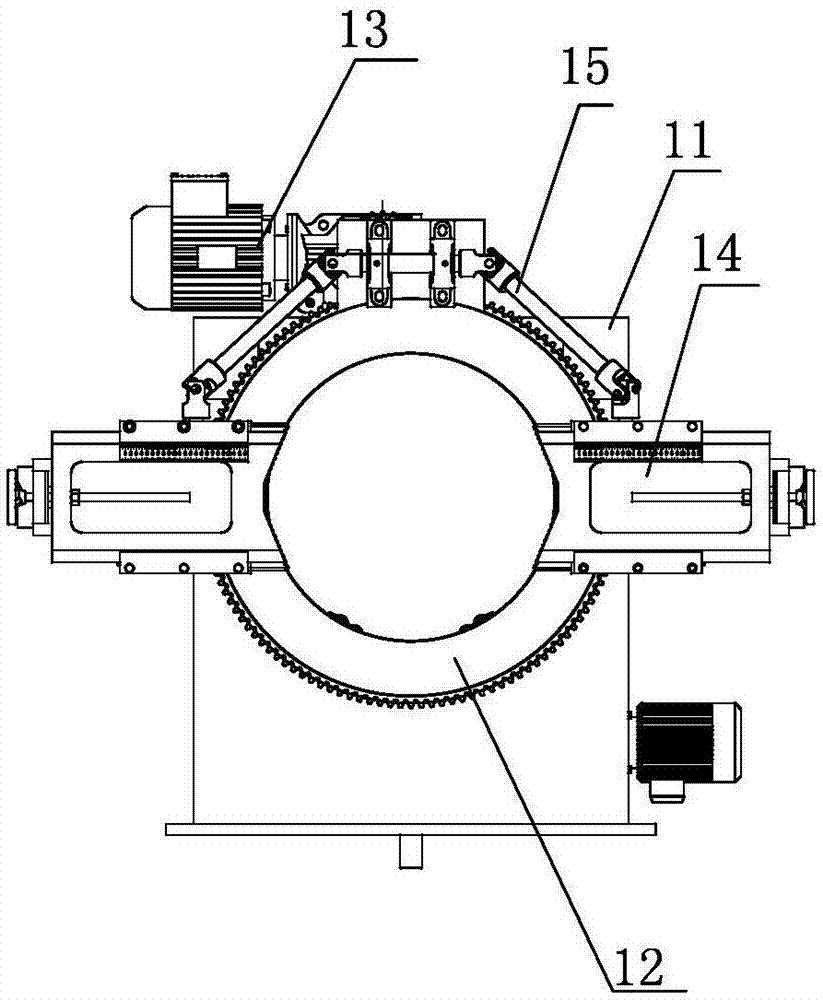

[0037] Such as Figures 1 to 12 As shown, a bidirectional synchronous rotating clamping device for steel pipe cutting is used for clamping and rotating the steel pipe to be cut. A bidirectional synchronous rotary clamping device for steel pipe cutting includes a clamping installation frame 11, a turntable mechanism 12, a clamping mechanism 14, a bidirectional synchronous clamping drive connection mechanism 15, a turntable drive mechanism 13, a lifting mechanism 16 and a control system.

[0038] The clamping installation frame 11 is mainly used for fixing and installing other devices of the present invention. The clamping installation frame 11 adopts a rectangular frame structure, and the middle longitudinal direction of the clamping installation frame 11 is provided with a feeding hole. The feeding hole is a circular through hole, and the feeding hole is used to pass the steel pipe that needs to be cut; the front end of the feeding hole is provided with a turntable installatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com