A method and system for recovering insoluble alkali metal catalyst in catalytic gasification ash

A recovery method and technology of a recovery system are applied in the field of recovery of insoluble alkali metal catalysts in catalytic gasification ash and slag, and can solve the problems of poor solubility, low recovery efficiency and high economic cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

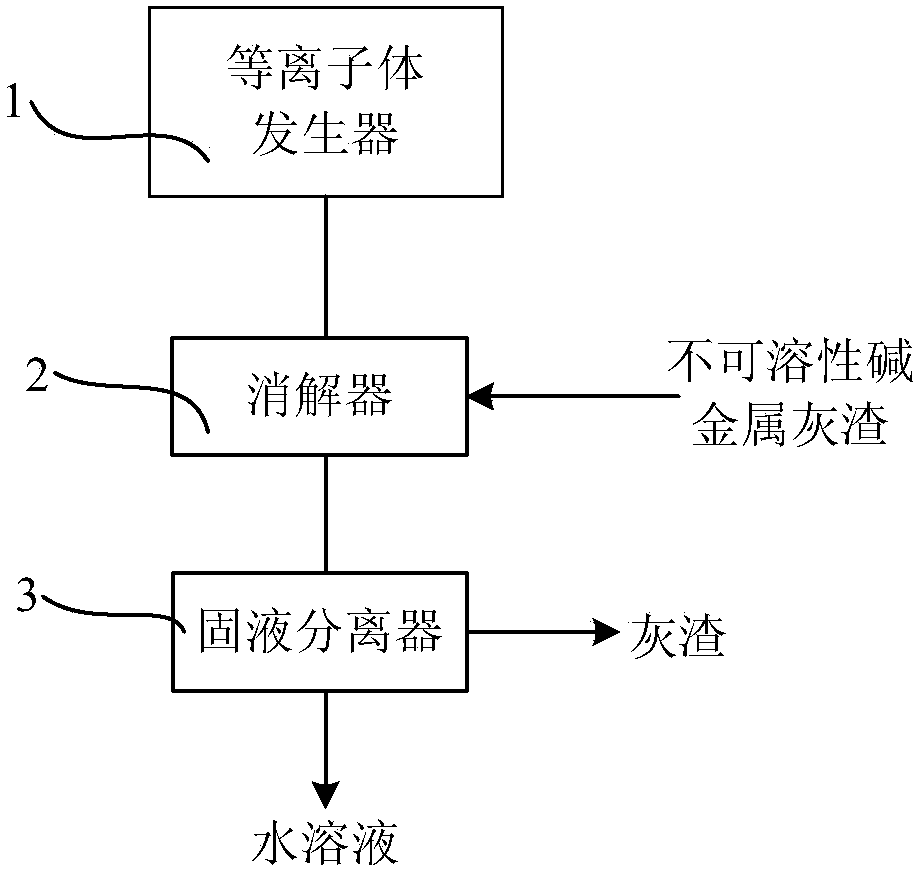

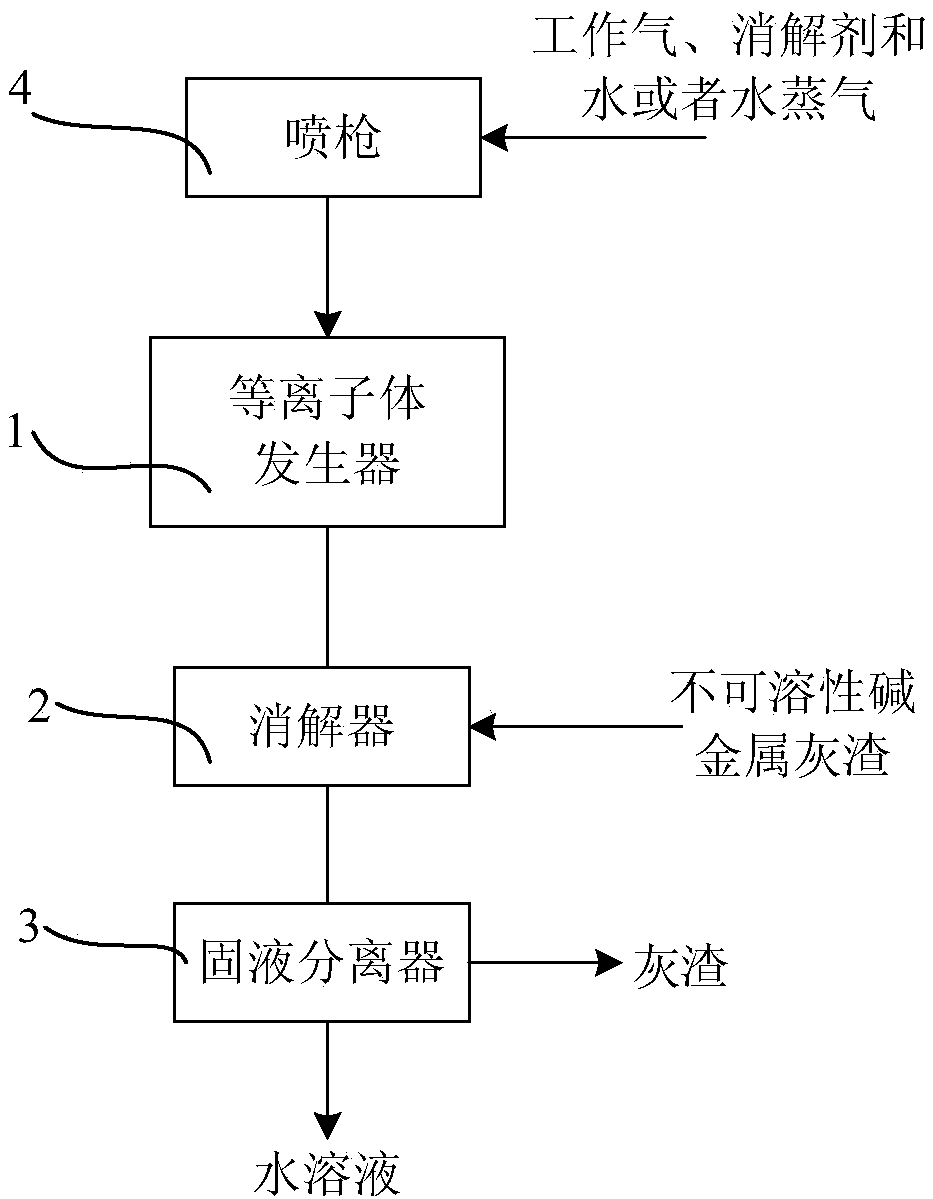

Image

Examples

Embodiment 1

[0077] Obtain insoluble alkali metal ash:

[0078] The coal catalytic gasification ash is subjected to water washing treatment, and the solid-liquid separation is carried out to obtain insoluble alkali metal ash and water washing liquid.

[0079] To recover the catalyst in the insoluble alkali metal ash:

[0080] 001) Detect the potassium ion content in the insoluble alkali metal ash, weigh a certain amount of digestant (calcium hydroxide), so that the molar ratio of calcium ion to potassium ion is 2, and add to the calcium hydroxide 1.5% polymer dispersant, and the mixture is ground in a wet mill until the particle size is less than or equal to 350 mesh.

[0081] 002) Inject the digester powder obtained in step 001) into a spray gun, and use the high-pressure airflow generated by a nitrogen compressor to entrain the digester powder with water vapor (the mass ratio of the water vapor to the insoluble alkali metal ash The mixture of 2) flows through the plasma charging unit in the pla...

Embodiment 2

[0085] The insoluble alkali metal ash used in the embodiment 2) is the same as that in the embodiment 1);

[0086] To recover the catalyst in the insoluble alkali metal ash:

[0087] 001) Detect the potassium ion content in the insoluble alkali metal ash, weigh a certain amount of digestant (calcium hydroxide) so that the molar ratio of calcium ion to potassium ion is 0.6, and add to the calcium hydroxide 0.5% polymer dispersant, and grind the mixture in a wet mill until the particle size is less than or equal to 350 mesh.

[0088] 002) Inject the digester powder obtained in step 001) into a spray gun, and use the high-pressure airflow generated by a nitrogen compressor to entrain the digester powder with water vapor (the mass ratio of the water vapor to the insoluble alkali metal ash The mixture of 3.9) flows through the plasma charging unit in the plasma generator at high speed, and the temperature of the plasma is controlled to 180°C.

[0089] 003) The mixture flowing through the ...

Embodiment 3

[0092] The insoluble alkali metal ash used in the embodiment 3) is the same as that in the embodiment 1);

[0093] To recover the catalyst in the insoluble alkali metal ash:

[0094] 001) Detect the potassium ion content in the insoluble alkali metal ash, weigh a certain amount of digestant (calcium hydroxide) so that the molar ratio of calcium ion to potassium ion is 1.95, and add to the calcium hydroxide 1% polymer dispersant, and grind the mixture in a wet mill until the particle size is less than or equal to 350 mesh.

[0095] 002) The digestion agent powder obtained in step 001) is injected into the spray gun, and the high-pressure air flow generated by the air compressor is used to entrain the digestion agent powder with water vapor (the mass ratio of the water vapor and the insoluble alkali metal ash The mixture of 0.5) flows through the plasma charging unit in the plasma generator at a high speed, and the temperature of the plasma is controlled to 160°C.

[0096] 003) The mix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com