Garment dyeing lining cloth and manufacturing method thereof

A garment dyeing and manufacturing method technology, which is applied in the direction of protective clothing, special outerwear, textiles and papermaking, and can solve problems such as insufficient elasticity and softness, inability to color, and clothing appearance defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

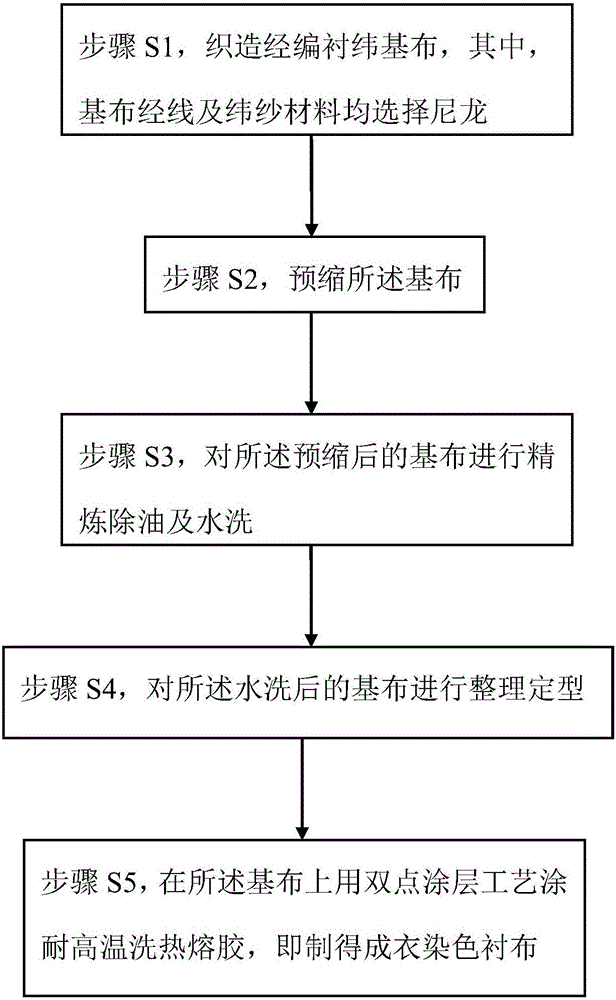

[0044] Step S1, weaving warp-knitted weft-inlaid nylon base fabric.

[0045] Use Ermeyer 24-needle warp knitting and weft inserting machine as the loom, the warp yarns are fully threaded, the warp yarn loops are knitted chain weave, the warp yarn material is nylon 66FDY 40D, and the weft yarn is nylon 6DTY 75D / 24F untwisted yarn. The weft density of the machine is 14 threads / cm, and the width of the upper machine is 220cm. When getting off the machine, the door width will shrink to about 205cm.

[0046] Step S2: Pre-shrunk the base cloth.

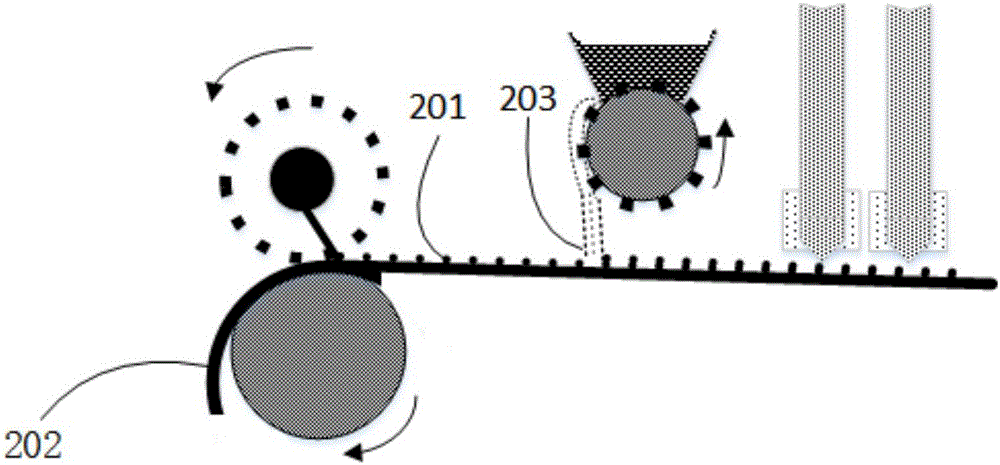

[0047] Specifically, the base is placed in a steam pre-shrinker, and pre-shrunk at a temperature of 145°C, a vehicle speed of 20m / min, and a tension-free state, so that the door width shrinks from 205cm to 135cm. After pre-shrinking, the base fabric becomes compact, fluffy and soft, with sufficient elasticity in the warp and weft directions, which can reduce scratches and snags during refining, degreasing and washing in open-width washing...

Embodiment 2

[0059] Step S1, weaving the woven base fabric.

[0060] Specifically, the Ermeyer 24-needle warp knitting weft inserting machine is used as the weaving machine, the warp thread is threaded through the needle (one empty guide needle is threaded through one warp thread), the warp thread looping structure is a knitting chain structure, and the warp thread material is nylon 66FDY 40D, the weft yarn is nylon 6DTY 75D / 24F, micro mesh untwisted yarn, the weft density of the upper machine is 15.5 pieces / cm, and the width of the upper machine is 220cm. When getting off the machine, the door width will shrink to about 202cm.

[0061] Step S2: Pre-shrunk the base cloth.

[0062] Specifically, the base is placed in a steam pre-shrinker, and pre-shrunk at a temperature of 145°C, a vehicle speed of 20m / min, and a tension-free state, so that the door width shrinks from 205cm to 135cm. After pre-shrinking, the base fabric becomes compact, fluffy and soft, with sufficient elasticity in the w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Square gram weight | aaaaa | aaaaa |

| Square gram weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com