Method for extrusion puffing of cereal fiber powder, and puffed cereal fiber particle

A technology of grain fiber and fiber powder, applied in the field of extruded grain fiber particles and extruded extruded grain fiber powder, can solve the problems of high oil and high fat in products, reduce losses, speed up the adjustment of structure, and improve the effect of acceptance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] The production of embodiment 1 upland wheat fiber powder

[0063] The dryland wheat raw grains purchased from Hongdong County Zhongyi Agricultural Development Co., Ltd. were crushed and ground with Dengfeng brand 6F-40 roller stone mill or 6F-38 roller steel mill produced by Shandong Sishui Xinfeng Flour Machinery Co., Ltd. Dryland wheat refers to wheat grown on hilly land and mountain slopes in arid and semi-arid areas and cultivated by natural precipitation. The dryland wheat used in this example is grown in some hilly lands and hillsides in and around Hongdong County, Shanxi. . In the above crushing and grinding, the vertical grinding disc is used, which greatly reduces the ash content in the flour. The speed of the stone mill is 20 rpm, the temperature is 45 degrees, and this kind of flour milling process that pays equal attention to the skin and heart greatly reduces the number of times the wheat is milled, and the aroma of wheat germ, protein, carotene, carbohy...

Embodiment 2

[0064] Example 2 Determination of Energy and Major Nutrients of Dryland Wheat Fiber Powder

[0065] The energy and major nutrient content of the obtained upland wheat fiber meal were tested according to standard methods. Energy and carbohydrates are tested according to GB / T 21922-2008; protein, fat and dietary fiber powder are tested according to the first method of GB 5009.5-2010, acid hydrolysis method of GB / T 5009.6-2003 and AOAC 991.43.

[0066] The main nutrient content of the upland wheat fiber powder prepared and detected according to the above method is shown in Table 1 below. Compared with common upland wheat flour, dietary fiber (wheat fiber powder 23.7g vs. common wheat flour 2.1g) and protein (wheat fiber powder 16.2g vs. common wheat flour 11.2g) content increased significantly, while carbohydrates (wheat fiber Flour 50.4g vs. Common wheat flour 73.6g) The content is greatly reduced. At the same time, the same weight of wheat fiber powder and common wheat flou...

Embodiment 3

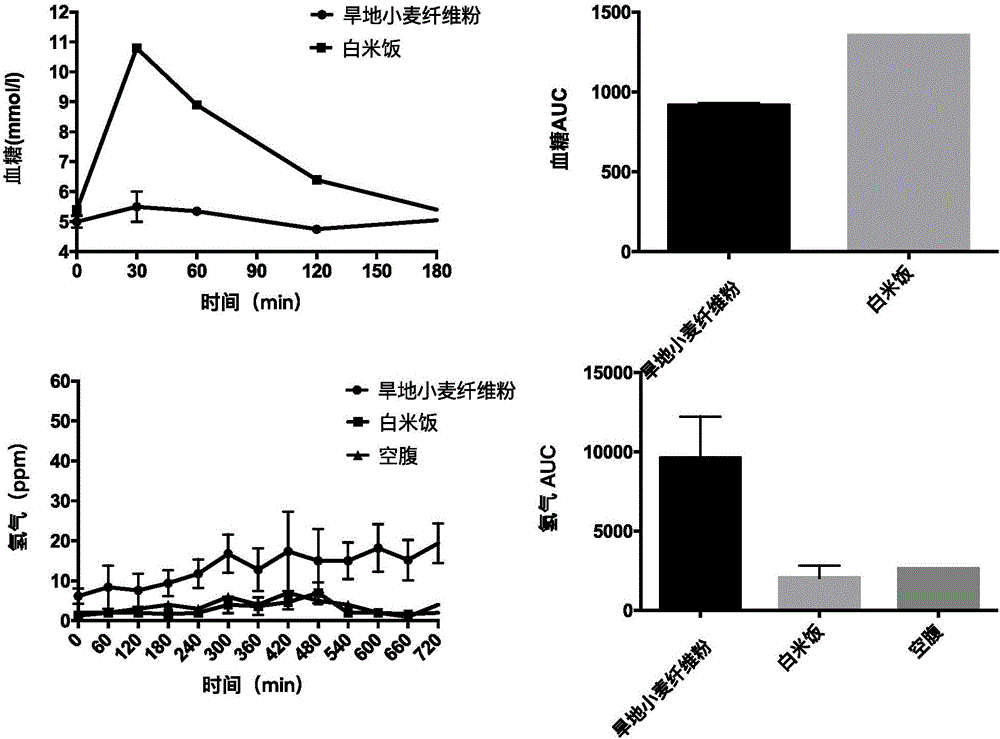

[0070] Example 3 Postprandial blood glucose and hydrogen production test of dryland wheat fiber powder

[0071] In this example, the postprandial blood glucose and hydrogen production were measured for the wheat fiber powder prepared in Example 1, and compared with white rice and various common prebiotics.

[0072]A total of 4 healthy subjects (aged 28-45 years old, BMI 18.0-22.3, without impaired glucose tolerance) participated in the test, fasted for 12 hours before the test, collected fasting exhaled hydrogen before eating on the day of the test, measured fasting blood glucose, and Test the blood sugar level within 3 hours after the meal, and detect the hydrogen production within 12 hours after the meal, every 60 minutes. Eat after the test. These 4 healthy subjects participated in 2 rounds or 3 rounds of testing, with several days between the two rounds of testing. Wherein, 1 experimenter took 20g upland wheat fiber powder prepared by embodiment 1 in the first round of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com