Crankshaft and method of strengthening shaft component

A technology of shaft parts and crankshafts, applied in the directions of crankshafts, shafts and bearings, rotating parts resistant to centrifugal force, etc., can solve problems such as the decrease of relative bending moment strength, and achieve the effect of reducing tensile stress, restraining stretching, and avoiding processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 Embodiment approach

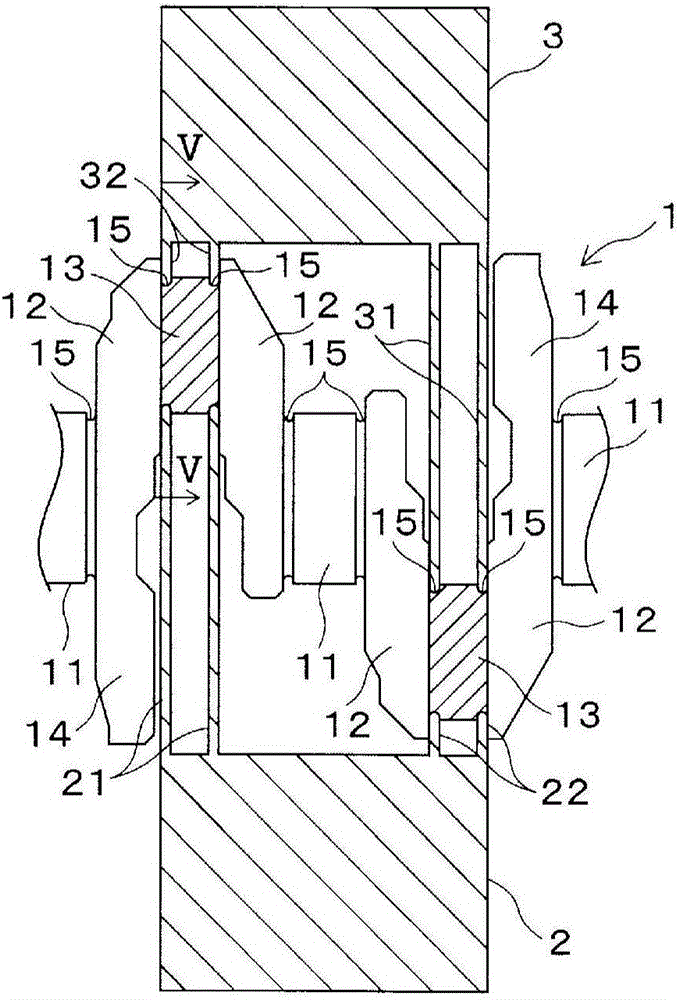

[0055] refer to Figure 7 and Figure 8 A second embodiment of the present invention will be described.

[0056] Figure 7 The side view shapes of the first lower punch 121 and the second upper punch 132 are shown. A pressing surface 133 is formed on the lower surface of the second upper punch 132 . The pressing surface 133 has a molding section A consisting of a substantially cylindrical curved surface within a range of 45° on both sides of the circumferential direction from the direction of the normal line I (direction from the center of curvature O toward the center line of the second upper punch 132). , the substantially cylindrical curved surface has a radius of curvature obtained by subtracting the pressing amount from the radius of curvature of the cross section of the chamfered portion 15 . Here, the so-called “pressing amount” refers to the thickness of the pressing surface 133 processed along the normal line I to the chamfered portion 15 . In the molding section...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com