Inner layer windowing multilayer flexible circuit board cover removing method

A technology of opening windows and inner layers, applied in multilayer circuit manufacturing, electrical components, printed circuit manufacturing, etc., can solve the problems of protective cover burrs, abnormal circuit tearing, uneven thickness of protective cover, uncontrollable laser depth, etc. Achieve the effect of reducing risk, good cutting depth and controlling scrap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

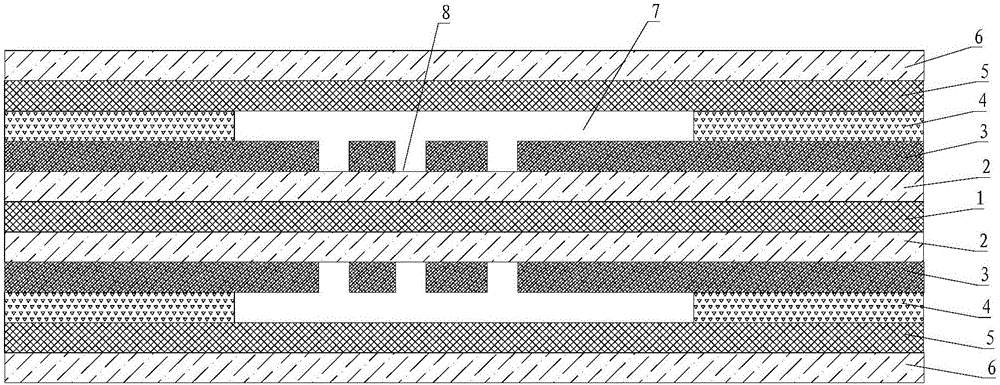

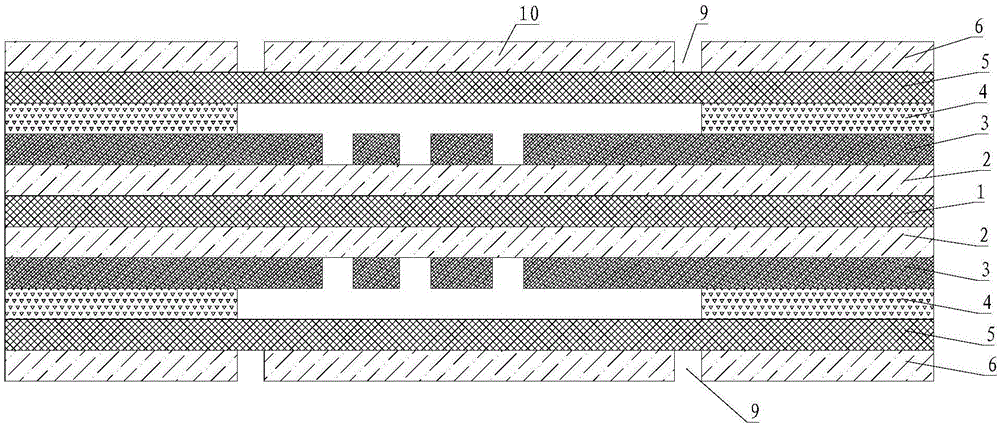

[0019] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

[0020] The most critical design of the present invention is: technology of the present invention, reserve a circle of copper-free grooves on the outer layer copper skin facing the window of the inner layer, and cut the outer layer FCCL along the copper-free grooves using laser cutting lines, the present invention It can effectively prevent damage to the inner circuit of FPC.

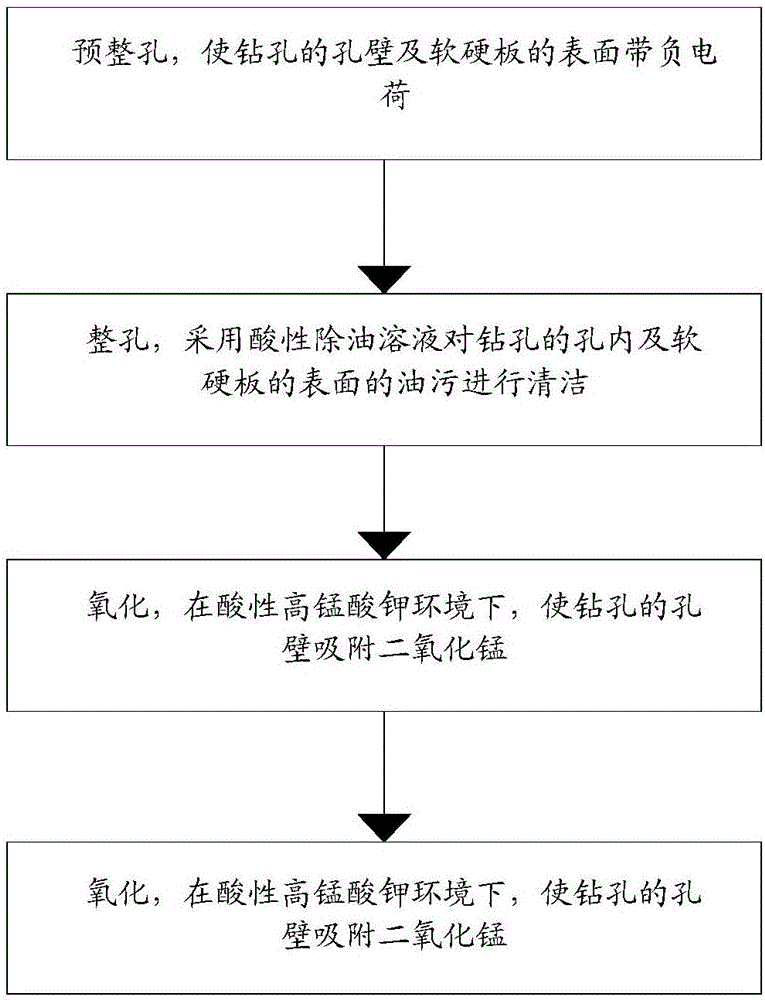

[0021] see figure 1 , the method for uncapping the multi-layer soft board with inner layer window opening of the present invention comprises the following steps:

[0022] S1. Perform copper electroplating on the multi-layer soft board with the inner window open, and set up a circle of copper-free grooves on the periphery of the protective cover facing the inner wind...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com