Apparatus for machining, particularly for cutting a tubular or round section body

A technology of mechanical processing and equipment, applied in metal processing equipment, sawing equipment, metal sawing equipment, etc., can solve the problems of difficult operation, expensive, large equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

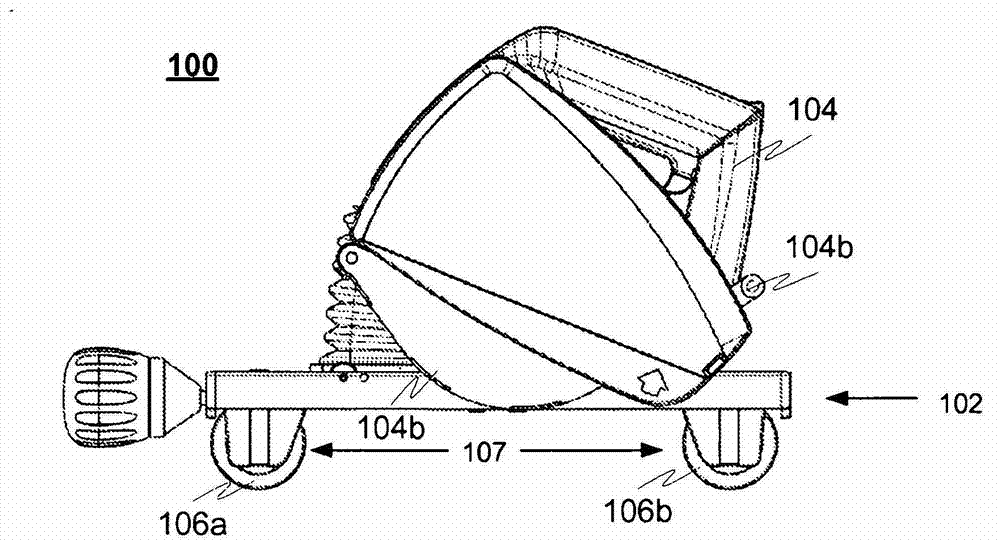

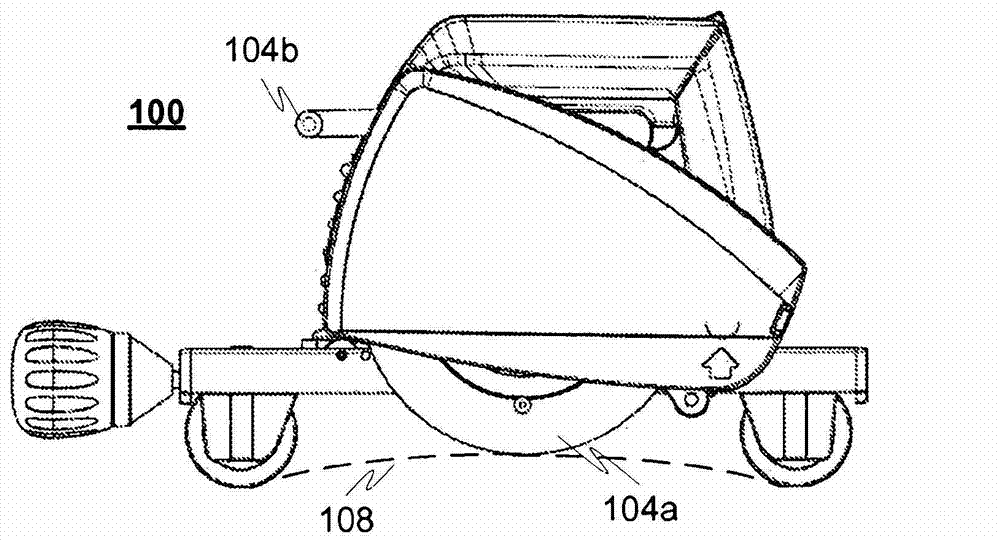

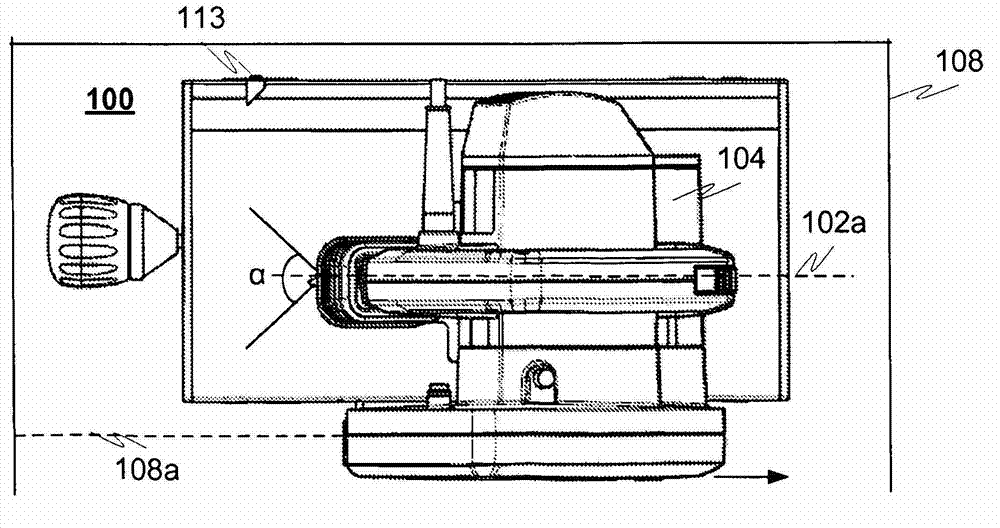

[0029] figure 1 and 5 shows an example device 100 in a transport state, wherein the tool part 104a is covered by a pivotable protective cover 104b, and figure 2 The apparatus 100 is shown in an operative condition, wherein the pivotable guard 104b is rotated such that at least a portion of the tool part 104a is exposed outside the guard 104 . The device 100 comprises a frame element 102 and a machining unit 104 for rotating a tool part 104a. Additionally, the example apparatus includes at least one first support element 106a and at least one second support element 106b for supporting the apparatus 100 on a workpiece 108 while the workpiece is being machined. The apparatus is also provided with adjustment elements, such as hinges or slide rails, for moving the tool part 104 a towards or away from the workpiece 108 relative to the frame element 102 . Thus, for example, during the process of cutting and / or beveling the part 108, the tool part 104a is moved toward the workpiece ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com