A method for non-destructive sampling and measurement of carbon cake layer in particle trap

A particle trap and non-destructive sampling technology, which is applied in the direction of measuring devices, internal combustion engine testing, machine/structural component testing, etc., can solve the problems of inaccurate sampling, carbon cake layer falling off, fragmentation, pollution, etc., to improve pollution situation, improving usage efficiency, and reducing usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1: A method for non-destructive sampling and measurement of carbon cake layer in engine particulate filter: Cut the particle trap into blocks of different sizes according to the density and step size of sampling in different axial and radial regions of the particle trap;

[0032] Number each sub-block, and reassemble the sub-blocks according to the numbering order to form a complete particle trap;

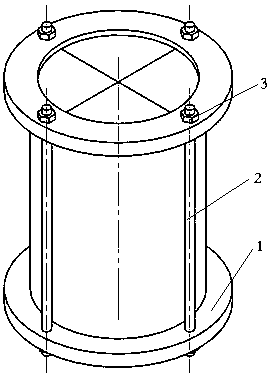

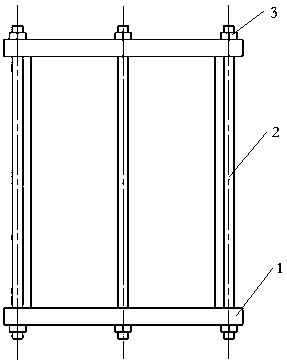

[0033] The assembled particle filter is wrapped with flexible high-temperature resistant material, then wrapped with copper skin, and then fastened with a stainless steel frame;

[0034] Pack the fastened particulate filter into the engine exhaust pipe, and carry out the soot loading test according to different engine speeds and loads;

[0035] After the loading test is completed, take out the particle trap from the engine exhaust pipe, disassemble and remove each numbered block in turn, and then sample and measure the soot on each block.

[0036] Such ...

Embodiment 2

[0040]Embodiment 2: The particle trap block 4 can be cut into equal parts by axially segmenting and radially dividing the particle trap, or calculating the soot distribution result in the particle trap according to CFD simulation , non-equal cut block.

[0041] The thickness of the copper skin layer 6 needs to be appropriate, and it should be selected according to the geometric size of the particle trap. It needs to be able to tightly wrap the split particle trap wrapped with the high-temperature-resistant asbestos layer 5. If the copper skin layer 6 is too thick, it cannot be tightly packed. On the other hand, if the package is too thin, it will lack sufficient strength to provide sufficient support for the particle filter after splitting.

[0042] Before the test, the blocks 4 were put together and tightly wrapped with a high-temperature-resistant asbestos layer 5 and a copper skin layer 6 for reinforcement. The through holes on the two ring-shaped frames 1 are used to comp...

Embodiment 3

[0045] Embodiment 3: Under the condition of ensuring the processing size of the limit boss on the circular frame 1 and the through hole of the screw rod 2, the size of the air flow hole should be increased as much as possible, so as to ensure that the exhaust gas entering the particle trap will not be excessive. Much hindrance.

[0046] The number of screw rods 2 between the two circular frames 1 depends on the size of the particle trap, and can be set as a connection with 4 holes or 6 holes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com