Capacitance type temperature compensation oil level measurement sensor

A measurement sensor and temperature compensation technology, which is applied to the liquid level indicator, measurement device, liquid/fluid solid measurement, etc. for physical variable measurement. It can solve the problem that the sensor does not have fuel temperature measurement components, cannot compensate for errors, and poor process technology problem, to solve the effect of low concentric positioning accuracy, high concentric positioning accuracy and good manufacturability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and examples, but the present invention is not limited to the scope of the examples.

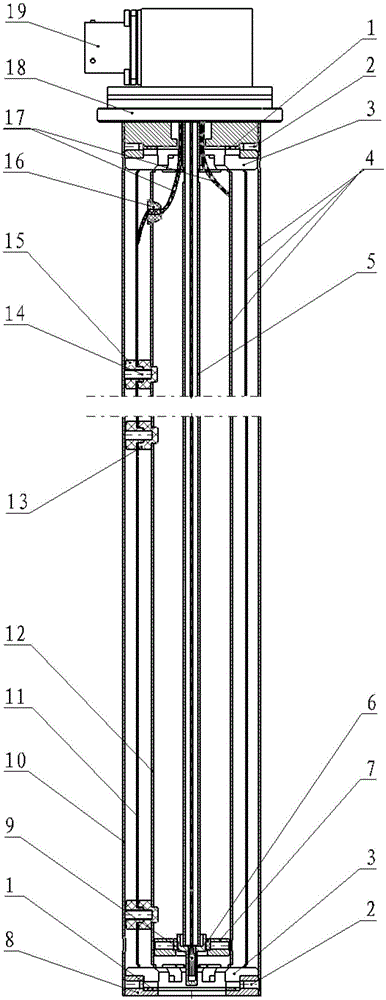

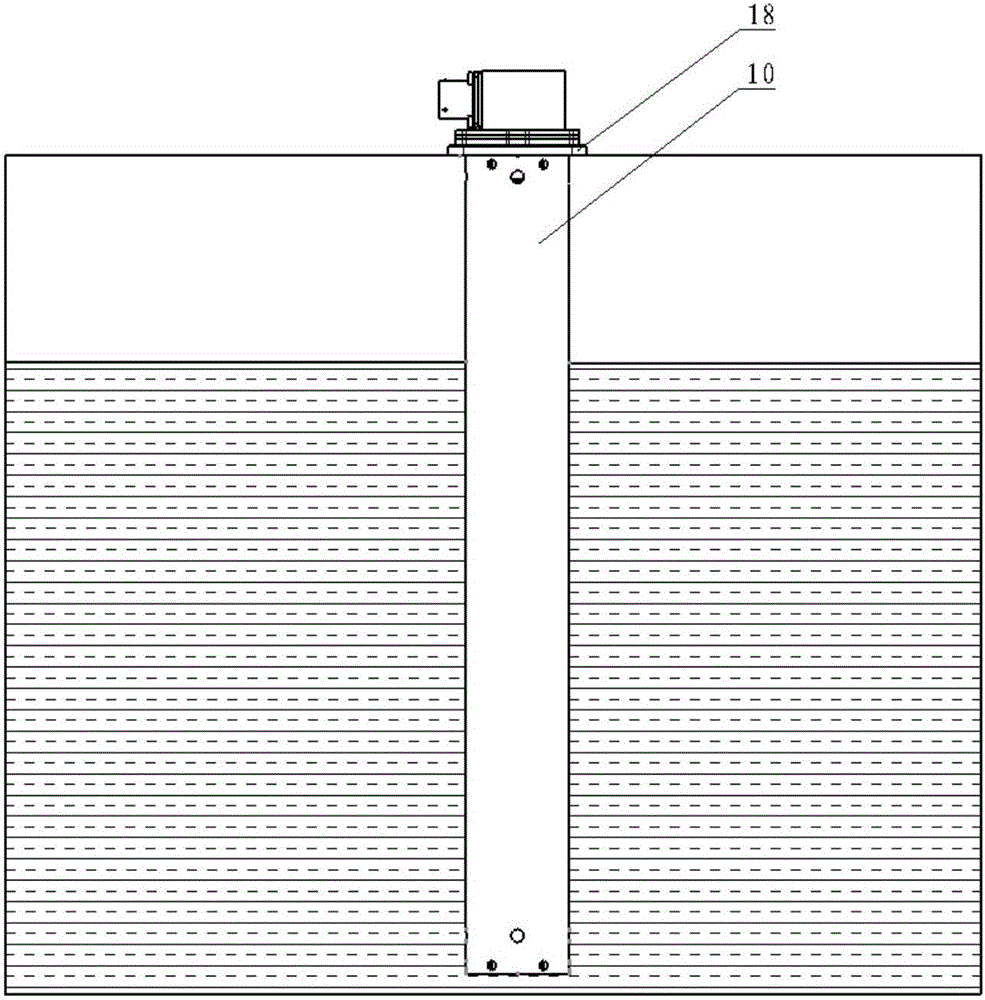

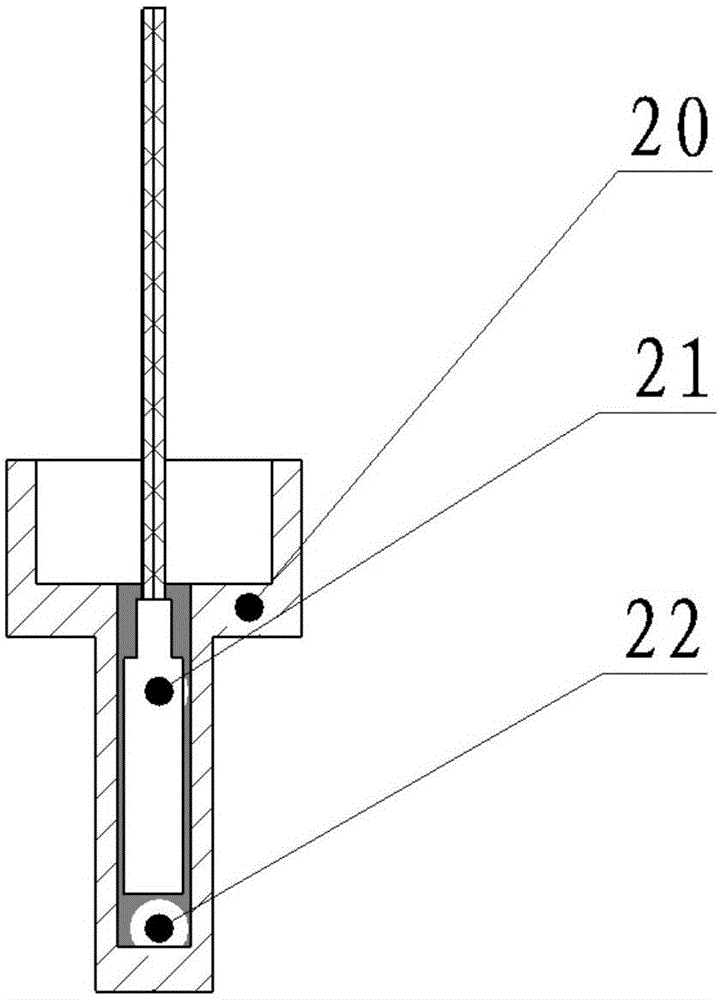

[0019] see figure 1 . A capacitive temperature-compensated oil level measurement sensor provided by the present invention includes an oil level measurement module 4 and a temperature compensation module 9 fixed at the bottom of the oil level measurement module, as a shielded outer tube of the entire sensor and a fixed support outer tube. Layer metal pipe body 10, middle layer metal pipe body 11 and inner layer metal pipe body 12. The oil level height measurement module 4 is composed of three coaxial metal tubes insulated from each other. The positive and negative probes are filled with a liquid medium that changes linearly with the liquid level to form a capacitor, and the oil level is obtained by relying on the change of the liquid medium in the tube. height and oil volume, and outpu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com