Whole-course load control method for supercritical direct current furnace

A supercritical once-through furnace and load control technology, applied in control systems, engine components, steam generation, etc., can solve the problems of backward operation mode, loss of economic benefits, loss of peak-shaving power of generator sets, etc., to reduce fluctuations, prevent Wasteful, responsive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] Below in conjunction with accompanying drawing, the present method invention is described in further detail, below is the explanation to the present method invention and the present method invention is not limited to following brief introduction, wherein disclosed data, function, code name etc. are not the limitation of this method invention, the technical field Personnel can obtain other data and functions to realize the purpose of the invention according to the solutions provided by the instructions and drawings without creative labor.

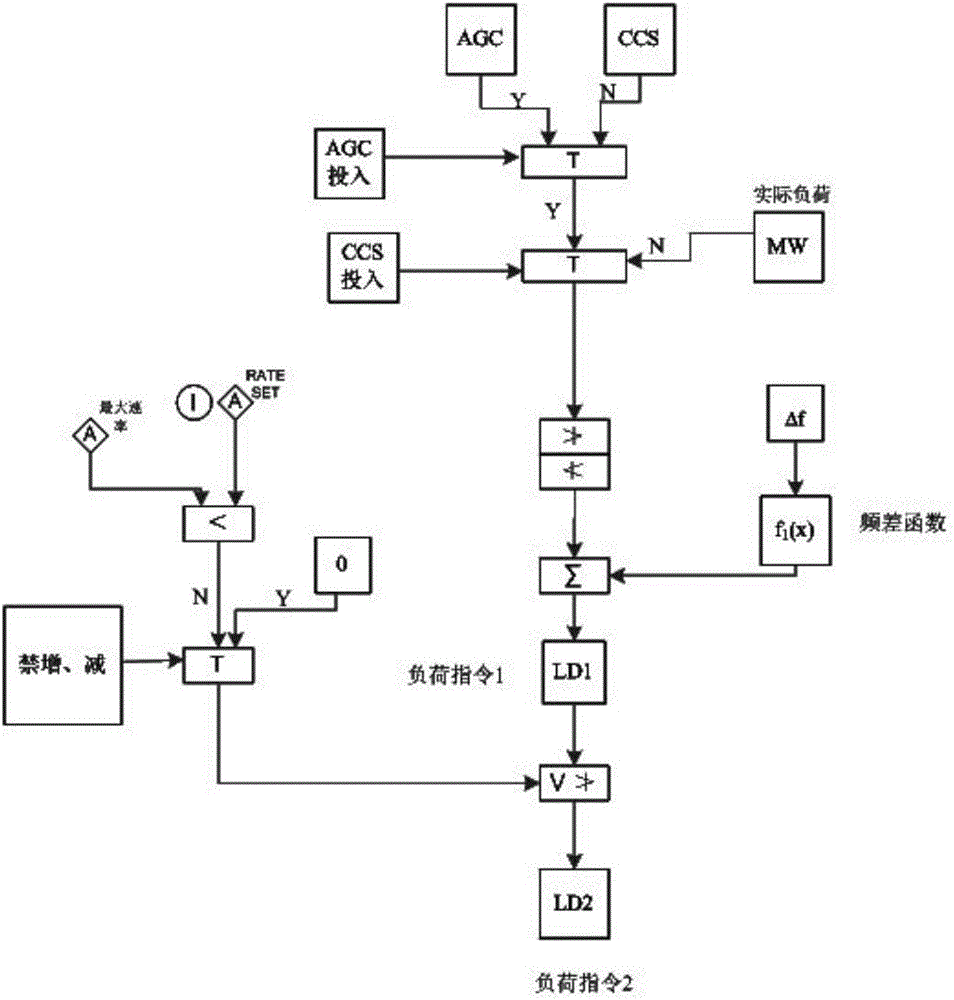

[0051] Such as figure 1 As shown, the input signal is selected by the switching function module. The input of the first switching function module is AGC and CCS commands. The output of the second switching function module is the output of the first switching function module, otherwise it is the actual load MW; the load processing center will limit the speed of the CCS and AGC commands and then add the frequency difference function f ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com