Flange fast and firm in connection

A flange and strong technology, applied in the direction of flange connection, pipe/pipe joint/pipe fitting, mechanical equipment, etc., can solve the problems of slowing down the construction progress, time-consuming and laborious, and failure of flange connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

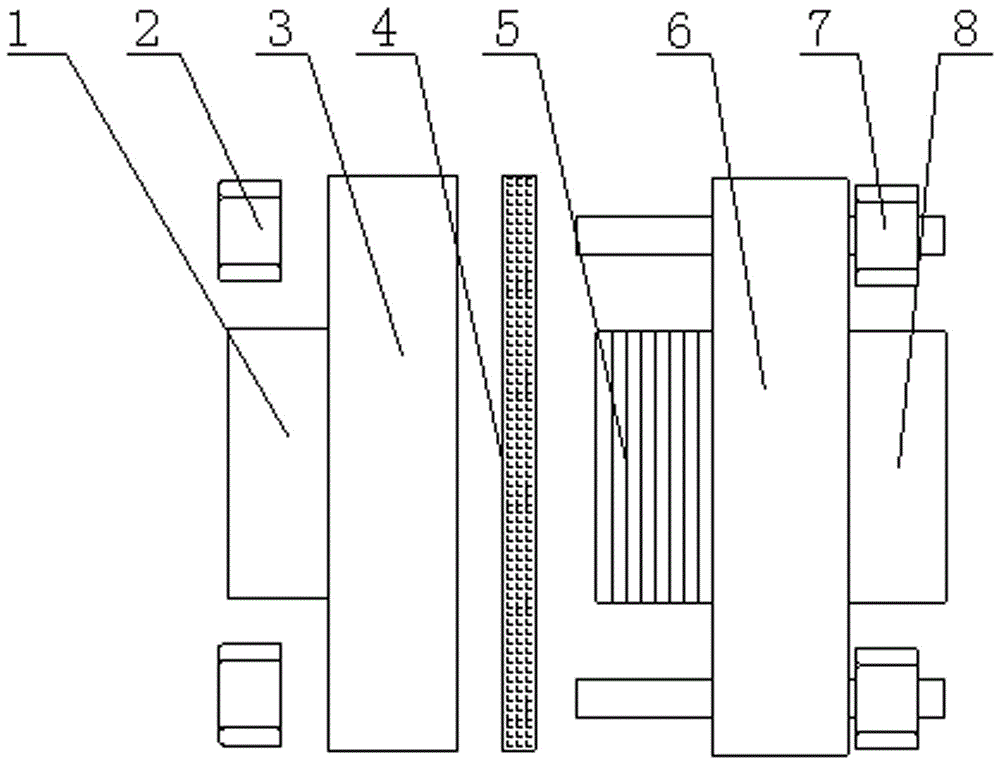

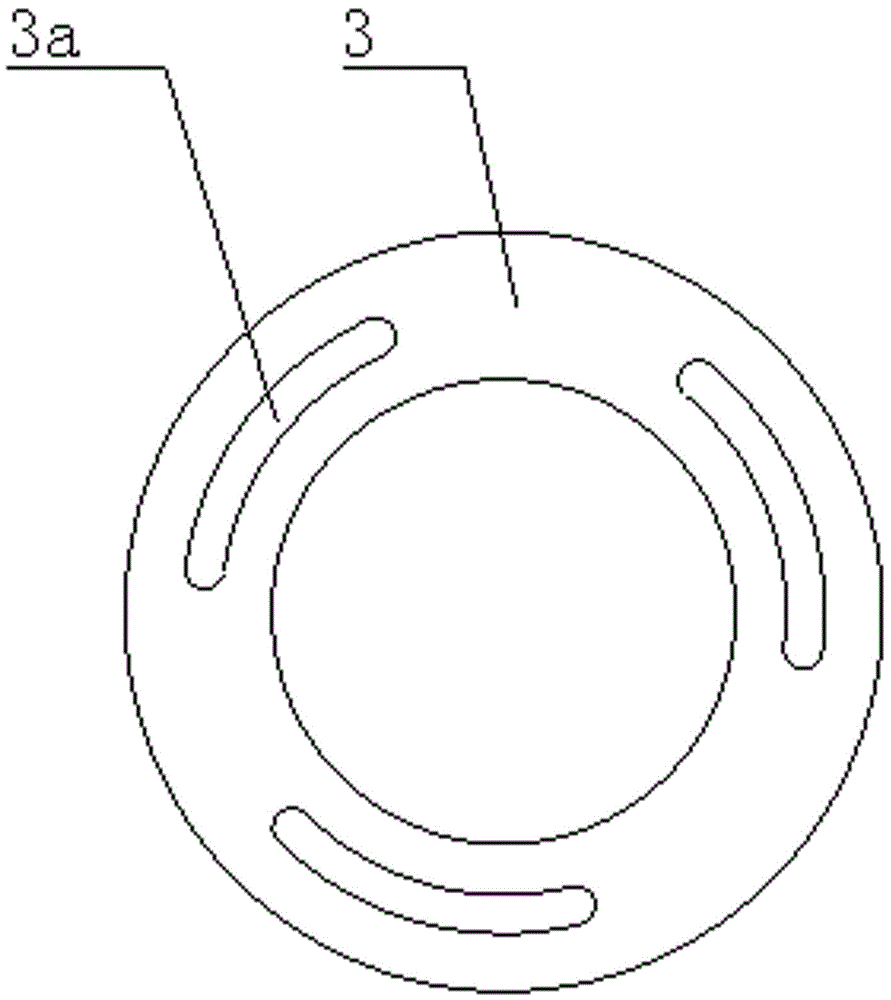

[0056] The fast and firm flange of this embodiment connects, as figure 1 with 2 As shown, including the first flange 3, the second flange 6, the sealing gasket 4, the fastening bolt 7 and the nut 2, the corresponding positions of the first flange 3 and the second flange 6 are provided with arc-shaped holes 3a respectively, The fastening bolts 7 pass through the arc-shaped holes 3a of the first flange 3 and the second flange 6 in turn to be threaded with the nut 2, and the sealing gasket 4 is arranged between the first flange 3 and the second flange 6. The second method The flange 6 is provided with an annular connecting block 5 near the side of the first flange 3, and the outside of the annular connecting block 5 is shaped on an external thread, and the first flange 3 is provided with a connecting groove matching the annular connecting block 5, and the inner wall of the connecting groove is formed with The internal thread matched with the external thread of the annular connec...

Embodiment 2

[0097] The fast and firm flange of this embodiment is basically the same as that of Embodiment 1, except that the mass percentages of the components in the first flange and the second flange are: C: 0.08%, Al: 1.33%, Zn : 0.61%, Si: 0.18%, Mn: 0.42%, S: ≤0.030%, P: ≤0.030%, Cr: 0.04%, Ni: 0.42%, Cu: 0.37%, V: 0.08%, Mo: 0.02% , Ti: 0.47%, B: 0.02%, Pd: 0.03%, Pt: 0.19%, W: 0.29%, Ta: 0.02%, Nd: 0.07%, Ce: 0.06%, Eu: 0.07%, Lu: 0.15% , Au: 0.46%, Ag: 0.85%, Ga: 0.02%, Y: 0.05%, Sn: 0.43%, Zr: 0.13%, Re: 0.05%, Os: 0.02%, Hf: 0.07%, Bi: 0.17% , glass fiber: 0.16%, calcium oxide: 0.26%, talcum powder: 0.25%, magnesium oxide: 0.29%, copper oxide: 0.18%, iron oxide: 0.39%, manganese dioxide: 0.49%, copper hydroxide: 0.09% , Iron hydroxide: 0.13%, Calcium hydroxide: 0.18%, Barium hydroxide: 0.16%, Sodium chloride: 0.06%, Calcium carbonate: 0.27%, Potassium nitrate: 0.35%, Magnesium chloride: 0.28%, Calcium chloride: 0.09%, potassium chlorate: 0.17%, the balance is Fe.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com