A wear-resistant and low-friction composite coating on the surface of titanium and its alloys and its preparation method

A composite coating and low-friction technology, which is applied in the direction of surface reaction electrolytic coating, metal material coating process, coating, etc., can solve the problem of aging of the resin-based film layer, accelerate the wear and tear of friction pairs, and reduce the coating Friction coefficient and other issues, to achieve the effect of expanding the use range and space, strong bonding force, and reducing the tendency of peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

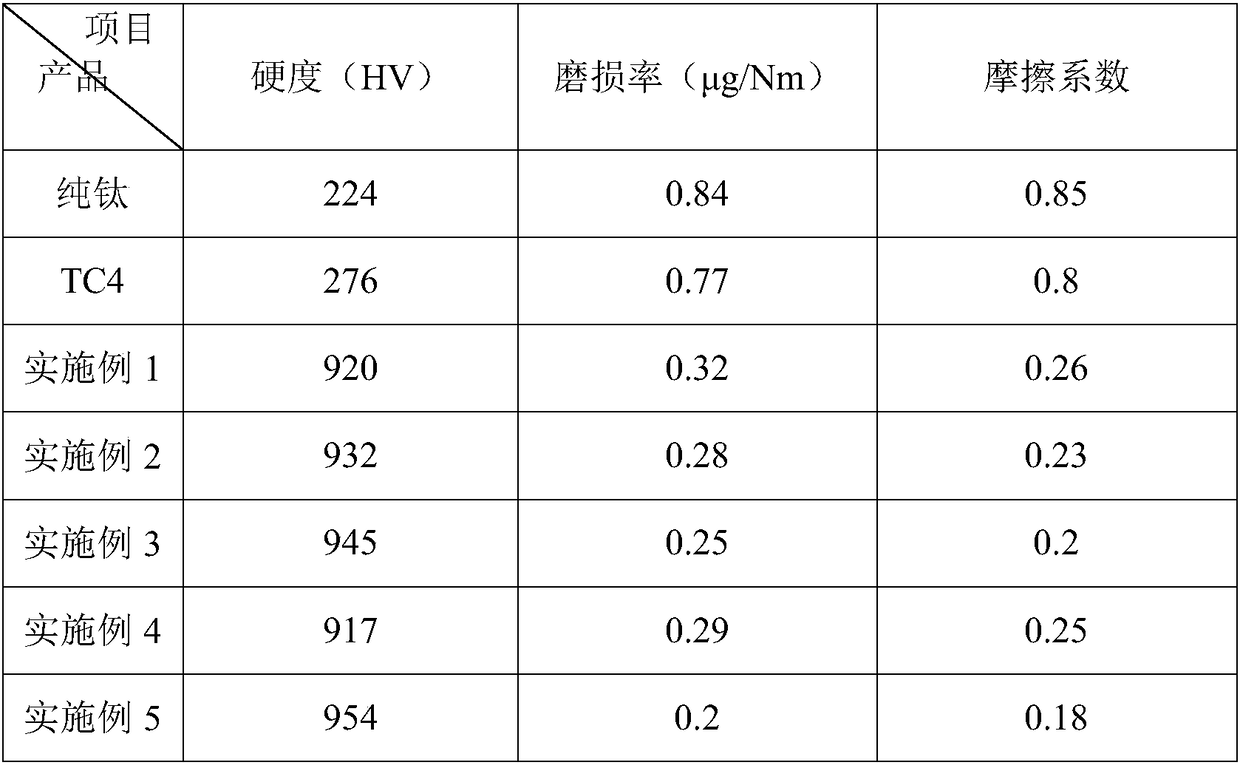

Examples

Embodiment 1

[0020] Using TA1 pure titanium as the substrate, the preparation method of the wear-resistant and low-friction composite coating mainly includes: using the micro-arc oxidation technology to prepare the pre-treated titanium in the graphite mixed electrolyte to prepare the precursor oxidation coating containing graphite, wherein In the micro-arc oxidation process, the voltage is 380V, the processing time is 20min, the frequency is 50Hz, and the duty cycle is 20%; the electrolyte composition is 10g / L Na 2 SiO 4 , 3g / LKOH, 2g / L nano graphite (thickness≤40nm, sheet diameter≤400nm), 40mL / L absolute ethanol and, 1g / L sodium hydroxymethylcellulose. Then plasma nitriding treatment is carried out on the precursor oxide coating, wherein the voltage is 400V, the treatment time is 2h, Ar / N 2 =0.5, vacuum degree 40Pa.

Embodiment 2

[0022] With TA1 pure titanium as the substrate, the preparation process of the composite coating is the same as in Example 1, except that in the micro-arc oxidation process, the voltage is 400V, the treatment time is 25min, the frequency is 100Hz, and the duty ratio is 10%; the electrolyte composition is 13g / L Na 2 SiO 4 , 5g / LKOH, 3g / L nano-graphite (thickness≤40nm, sheet diameter≤400nm), 50mL / L absolute ethanol and, 1.5g / L sodium hydroxymethylcellulose. In the plasma nitriding treatment process, the voltage is 450V, the treatment time is 2.5h, Ar / N 2 =0.1, vacuum degree 50Pa.

Embodiment 3

[0024] With TA1 titanium alloy as the substrate, the preparation process of the composite coating is the same as in Example 1, except that in the micro-arc oxidation process, the voltage is 410V, the treatment time is 25min, the frequency is 100Hz, and the duty ratio is 10; the electrolyte composition is 12g / L Na 2 SiO 4 , 2g / LKOH, 3g / L nano-graphite (thickness≤40nm, sheet diameter≤400nm), 50mL / L absolute ethanol and, 1g / L sodium hydroxymethylcellulose. In the plasma nitriding treatment process, the voltage is 450V, the treatment time is 3h, N 2 Atmosphere, vacuum degree 50Pa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com